Howdy,

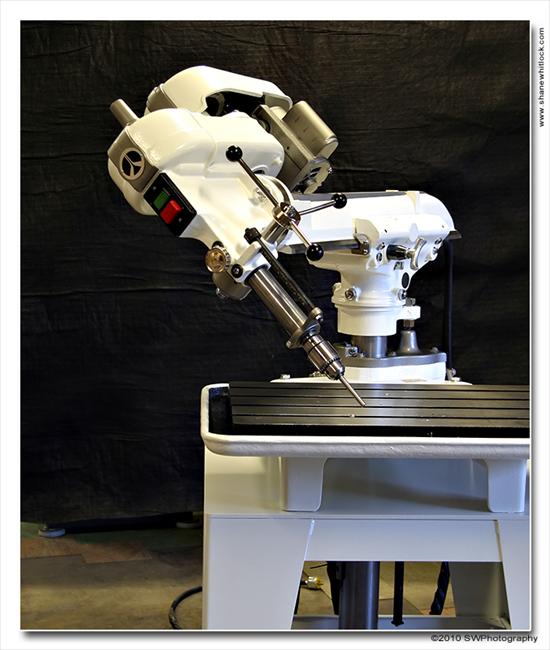

Still shopping for a drill press. What are the benefits and drawbacks to a radial arm drill press Versus a regular drill press?

I am looking at the Grizzly G 7946 Radial Drill Press

Regular Drill press G7944, RIDGID DP-1550, Porter Cable PCB660DP

I am upgrading from a Delta Bench top drill press. Thanks

Joe

Reply With Quote

Reply With Quote

, but you've got to be kidding, or gloating.

, but you've got to be kidding, or gloating.