I was in two minds whether to post this, but since the method is a practice, it would be great to get feedback, since the strategy I have come up with is complex. Can you do this another way?

Each row has 4 drawers, and these will be shaped to match the bow across the chest.

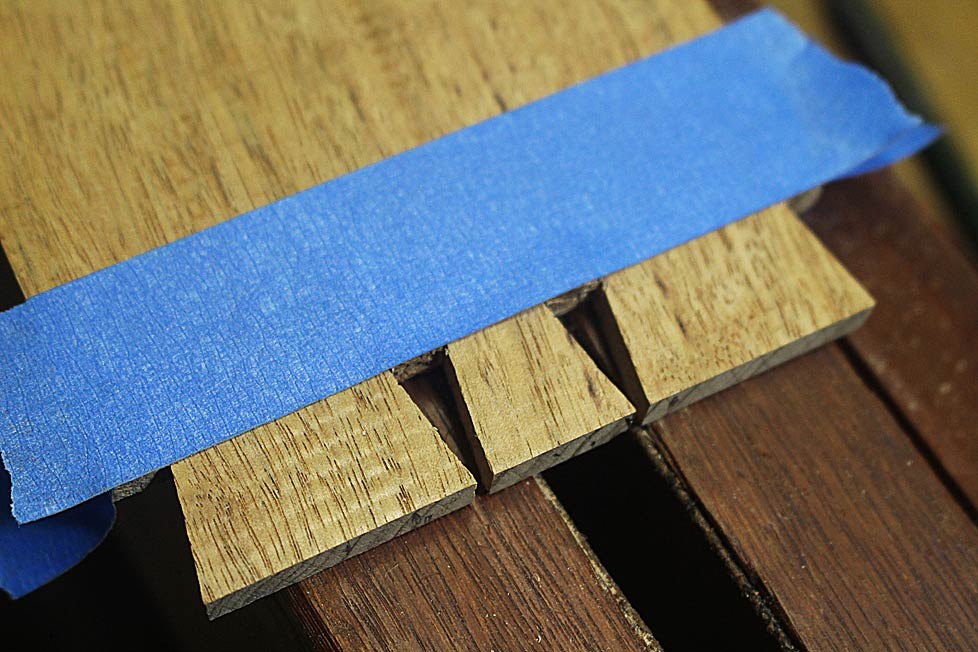

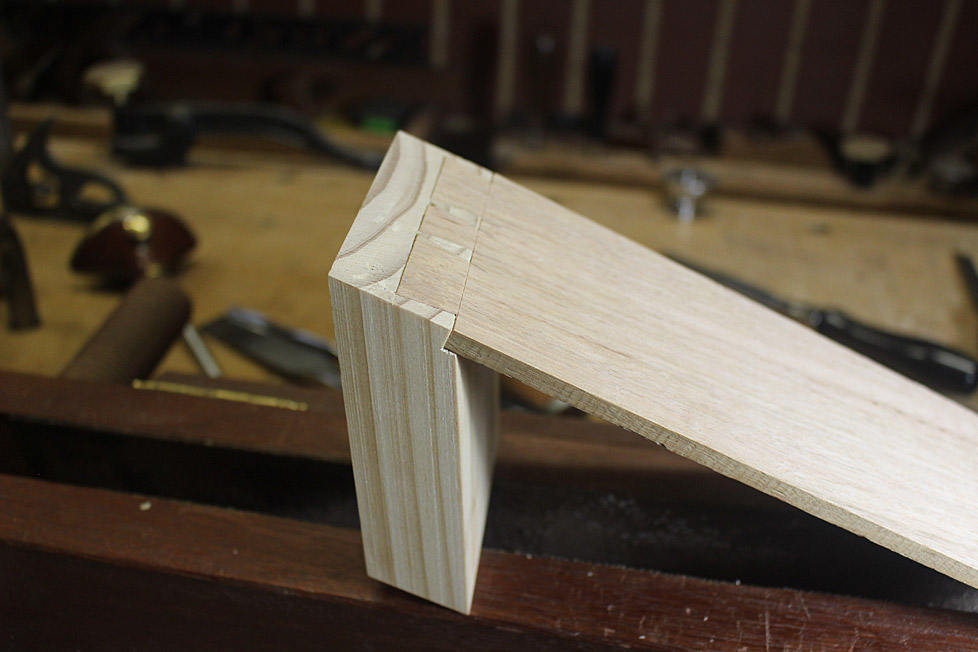

At the start, the drawer fronts are to be left straight. This maintains the reference sides. The ends of each drawer front have been bevelled to match fit the bow of each drawer blade.

This is a fitted (practice) drawer front (posted last time) ..

The drawer side has been dovetailed to the obtuse angled side (again, details in my previous post: http://www.inthewoodshop.com/Furnitu...tWeekend8.html) ...

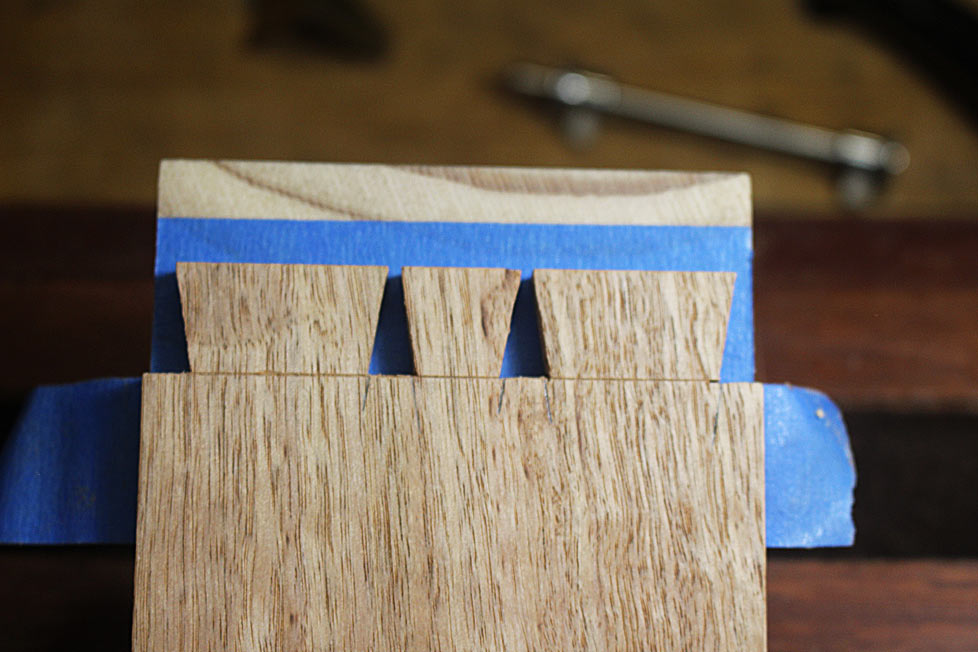

The need now is to dovetail the acute angle ...

This is where it gets interesting. It you look at the lines drawn on the drawer side, if made coplanar with the drawer front, the dovetails will need to me cut at an angle. That is much too complicated, and likely to be a poor fit.

Then, if the baseline is cut square (as usual), the dovetail will end up in the centre of the side (and not extending up from edge of the board).

The only way I could come up with for a fit that simplified the tail board was to rebate the pin board, so ....

The rebate needs to be as deep as the drawer side (for a flush fit), and square to the side (so the baseline of the tail board fits flush).

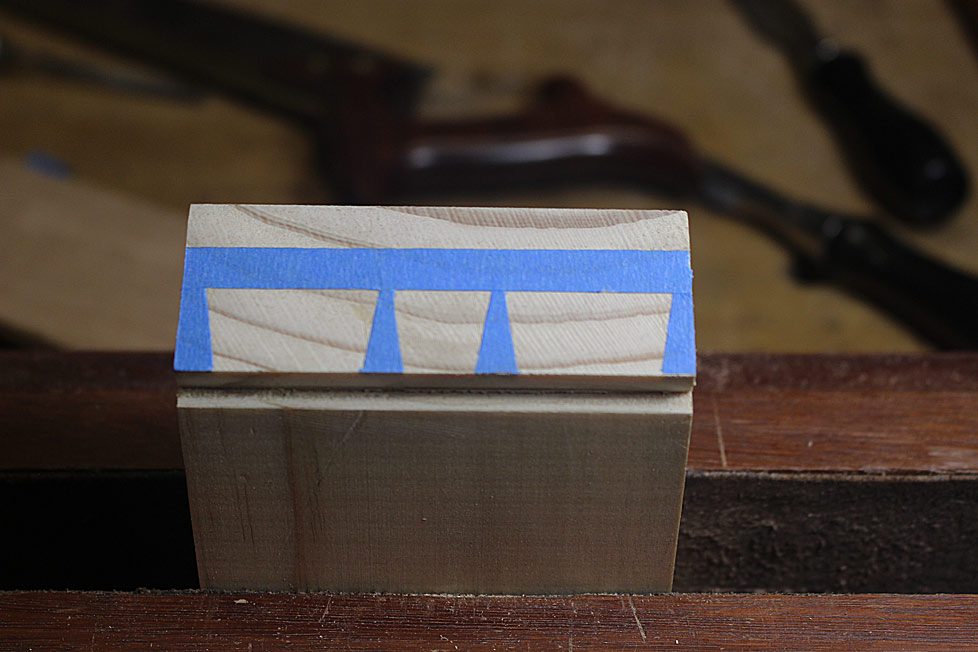

The first step is to mark the baseline ...

On the piece above, you can also see the rebate markings.

The rebate is now cut parallel to the side ...

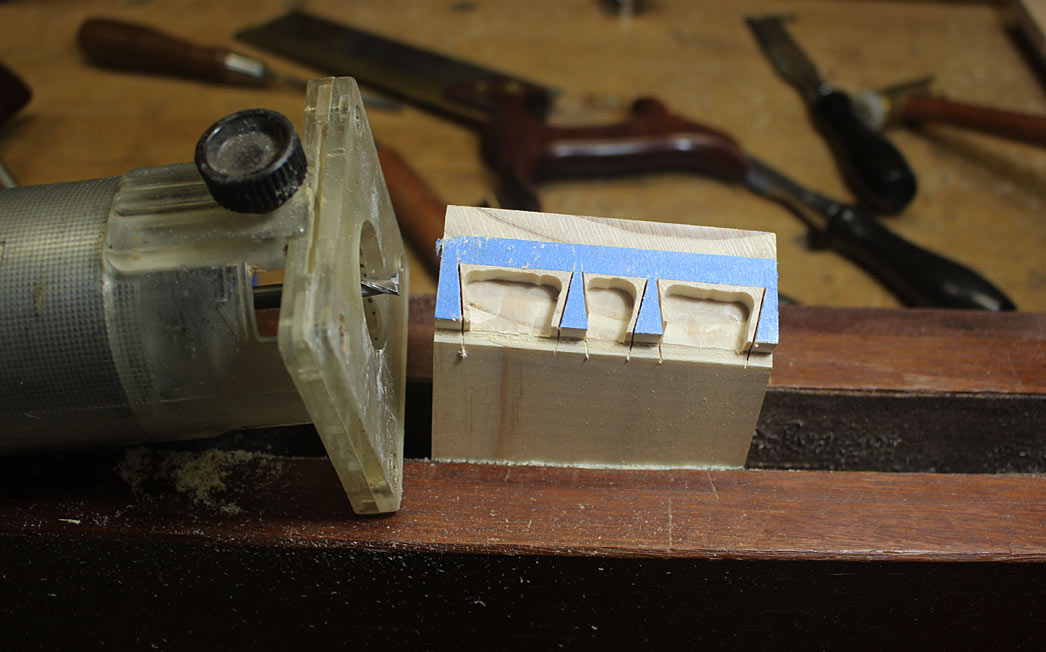

Remove some of the waste with a chisel ...

Now that rebate needed to be both straight and flat. It needs to be an equal depth along its length.

It could have been chiselled, but that is less efficient. A shoulder plane as this would not ensure a square shoulder without extra work to create an absolutely square edge for a tight fit. In the end I came up with this idea to plane it using a LN Edge Plane.

A spacer was attached to plane to the 1/4" depth ...

The finish was spot on ...

Reply With Quote

Reply With Quote