Hi everyone;

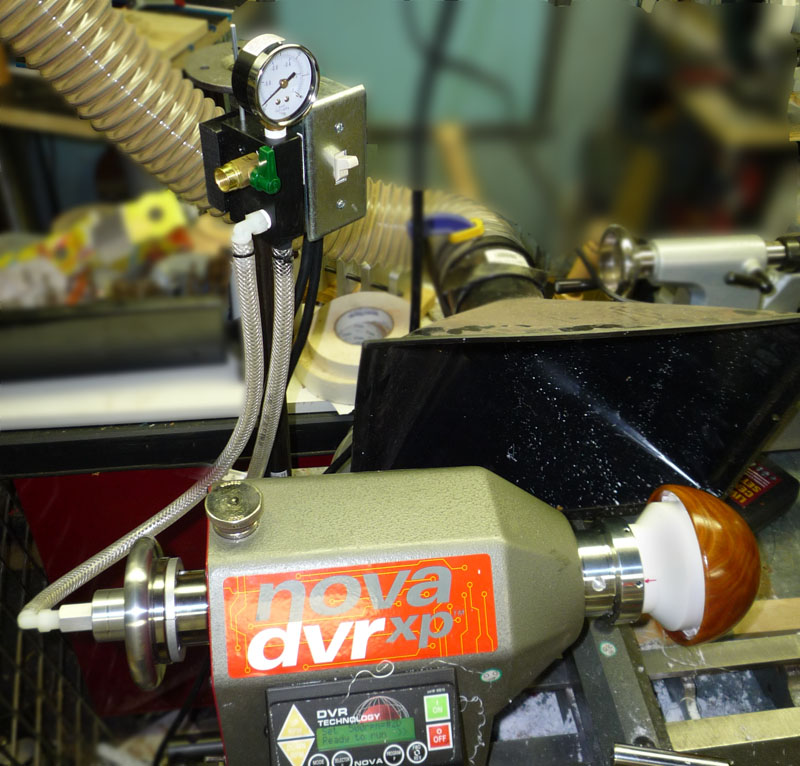

I have completed the installation of my vacuum system. I am using a vacuum pump from the hospital setting so it comes complete with the little glass jar and filter on the intake side. Also, a little hand screw to let in by-pass air for vacuum control.\

I have been having trouble with the Nova vac attachment, it leaks like a sieve. I think it is intended for a shop vac and depends on high volume air flow, which in not possible from a vac pump. So, I built a new adaptor using an old sealed bearing and a piece of 1/2 inch aluminum tubing to attach the hose to it. Works pretty well even though I think there is still some leaking going into the handwheel. I get 22" when putting my finger over the tube and only 17" with the vac chuck and a piece of solid wood on it.

Still the hold is good and workable.

Looking forward to using it on a Spalted Maple bowl currently in progress.

Peter F.

tn_IMG_2922.JPG tn_IMG_2919.JPG

Oops; This picture was not intended, but it is my latest project. Three Turkins Whorls, these are drop spindles with the cross pieces removable for easy storage. The wool is wrapped around the cross pieces and then spun into yarn, when it is about 3 feet long it is wrapped around the cross pieces and the spinning continues. When done it makes a ball of yarn when you pull out the cross pieces and then it can be used to knit stuff.

Reply With Quote

Reply With Quote

Good job-you'll wonder how you ever got along without it.

Good job-you'll wonder how you ever got along without it.