Good Day to All Creekers,

This thread has been quiet for a while.

Life does not always go the way we planned.

At any rate, I am aiming to resume building my chair...

hopefully within the next two weeks.

It seems that as a hobby woodworker, all the things that pop up in life,

do so at the expense of shop time.

I imagine many wish they could find more hours to play in the sawdust?

I'm gonna blow the dust off of my half-chair next week.

There are tumbleweeds blowing through my ghost-town, I mean, workshop.

It's gonna be quite a trick to figure out what I was gonna do next?

I did not see my long layover coming...

but I kinda wish I had left myself a note.

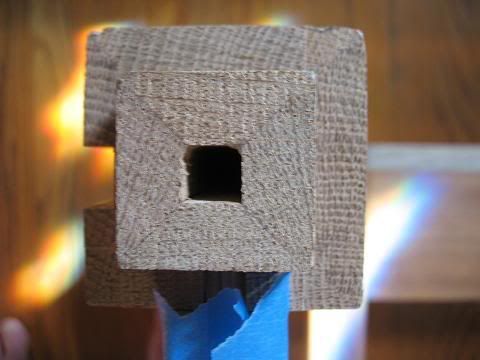

(Dear me: handtune the backrest tenons and do a dry test fit before glueing)

Hope to see you in the sawdust,

and soon!

Walt

ps Anyone building a Morris chair in progress?

Reply With Quote

Reply With Quote