My New Bench arrived sort of today. Some of the materials anyway. I had it sawed up at a Living History show I was demoing at, by a miniature Sawmill powered by a miniature Steam Engine. It stared out as a salvaged Pin Oak log 5 ft long.

Its been stickered in storage inside a friends Quonset building for 7 or 8 years. He needed the space so he delivered it today.

1 - 4¼ by 10¼ by 5ft

2 - 2¼ by 7½ by 5 ft

1 - 2 1/8 by 6 by 5 ft

1 - 2 3/4 by 7½ by 5 ft

1 - 1 by 7½ by 5 ft

1 - 1 by 9½ by 5 ft

1 - 1 by 6 by 5 ft

1 - 1 by 5 by 5 ft

It will reside in my basement for a month while it aclimates to the temp and humidity, 58° and 28% , should give me time to figure out how to work it up into a bench.

I have some 4 by 4 oak dunage material from steel shipments in the past, but to keep the weight down and conserve my precious supply of Oak, I think I will make the foundation from pine 4 by 4's from the lumberyard.

I have no idea of the brd ft in the pile.

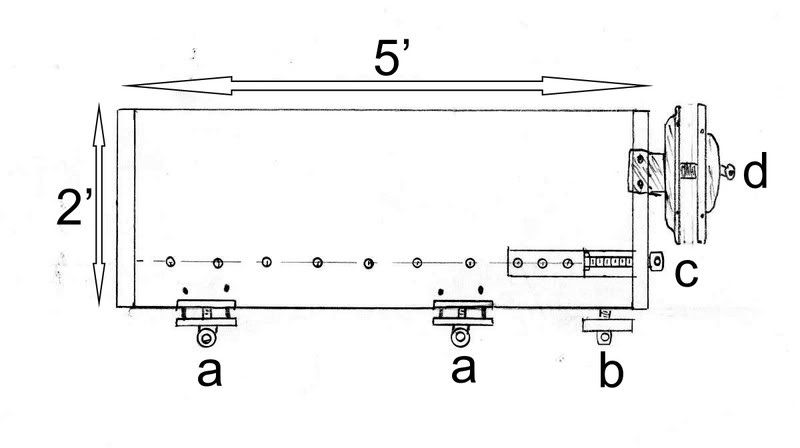

In my mind at the moment it will have a regular leg vise like the old benches on one side at the end, an emmert clone by Columbia on one end, and two regular old vices from school benches on the other long side. Still debating if I should put a tail vise on it.

Jr.

Jr.

Reply With Quote

Reply With Quote