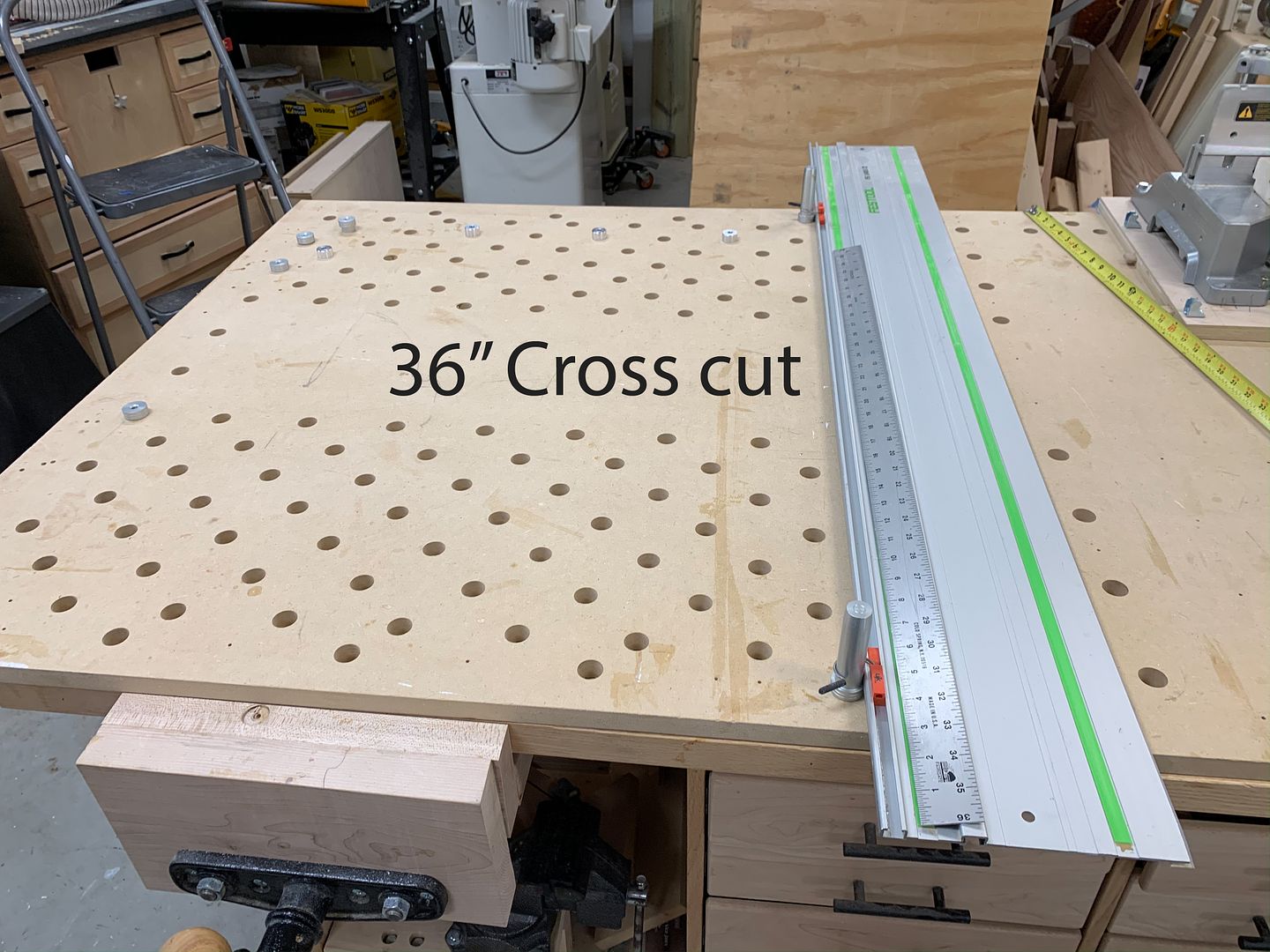

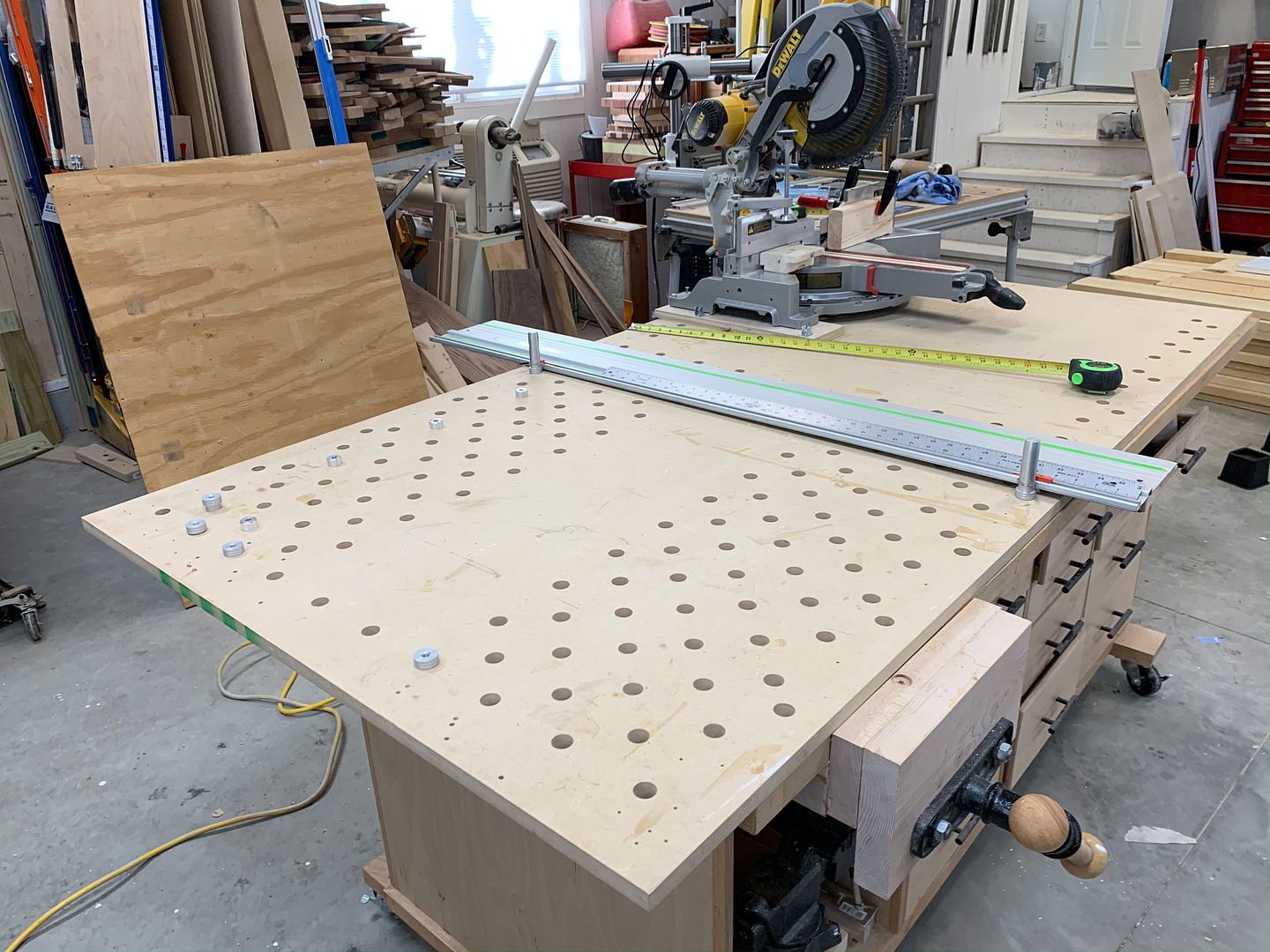

I'm looking at some options to build a table that can serve a few purposes like sanding, outfeed, assembly, domino, tracksaw, etc. and have a curiosity question. My initial inclination was to just buy an MFT/3 and use it. Then I gravitated towards mounting an MFT/3 on top of a cart. Now, I'm thinking of other options but here is my question. Does anyone find value in the actual MFT/3 when they have a table saw and kapex/miter? Thinking about how I would use it, I can see myself using it simply for track saw breakdown, but not miter or small cuts. So, is the MFT 20mm hole pattern all that important when not using it for miter and setup purposes?

Part of my question stems from the cost of the MFT itself. Part from the fact that my hold downs and dogs are all 3/4. And part from the fact that I want something more customized than just the MFT itself. My plan would be to have something around 30x72 that rolls up behind my table saw. But also, when desired I can roll it out and into middle of room, and flip up my sawstop folding outfeed. Keeps equipment footprint down when needed.

So far, I'm looking at ideas like this for inspiration, but again want to know how necessary people find the actual MFT hole pattern:

Made from Bora panels: https://www.reddit.com/r/workshops/c...y_for_about_a/

Made with MFT sitting on top: https://thewoodwhisperer.com/product...-cabinet-plan/

An actual MFT top fitted to kreg table/frame: https://forums.woodnet.net/showthread.php?tid=7347423

Thank you.

Reply With Quote

Reply With Quote