I've struggled with plan D, my go to is plan E and F (Elves and Fairies)......

I've struggled with plan D, my go to is plan E and F (Elves and Fairies)......

Well using an appliance handtruck is second best to getting a narrow pallet jack - you would move it just like you move a refrigerator. Watching the driver try to move it with a standard pallet jack will be a mess. If the freight company strapped it down on a regular pallet, then you should be okay.

Oliver move link. I lost the web site link. I think the angled support is hinged somehow to the base and lowered off vertical with a come along.

Bill D

2F7A9302-3139-49BF-87F8-F07C5D50010A.jpg

Well plan A worked. We used the pallet jack to get it up to the garage and found out it was too tall. We took it off the large crate, tilted it and dragged it in the rest of the way. Crate came in great condition no damage very happy. The driver got enough Starbucks coffee to last almost a week.

Last edited by Michael Sebar; 02-28-2023 at 5:16 PM.

Dave in answer to your question

1) drill press, no

2) router, mine is cordless, and mostly wood, so yeah it has a brake, as soon as I stop pulling it it stops cutting

3) Shaper, yes DC current injection

4) tablesaw, yes DC current injection

5) band saw, yes, homemade DC current injection

A blade brake on a large band saw is wonderful, I wouldn’t be without it…..Regards, Rod

Last edited by Jim Becker; 02-28-2023 at 7:45 PM. Reason: fixed quote tagging

My MM16 has a foot brake. I've not used it very often, but it's been used during those few times that the machine needed stopped "now" and it was not practical or not safe to take hands off the workpiece. Required? No, at least for most situations. Nice to have? Absolutely.

--

The most expensive tool is the one you buy "cheaply" and often...

What's the braking mechanism on these things? Mechanical, electronic? Does something pinch the wheel, a pad press up against the wheel, have an actual disk or other brake on the shaft?

I want to make a brake for my 18" Rikon and have some ideas but I've never looked at the mechanism for one. There are many times I wish I had a brake.

JKJ

John, it's a combination of both a microswitch to kill power to the motor while at the same time putting the brakes on the wheel...literally. You stomp on the pedal and the machine is stopped "really fast". That pedal doubles as the mount point for the johnson bar and caster for mobility on my machine, too.

--

The most expensive tool is the one you buy "cheaply" and often...

Do the brakes have some type of brake pad? Pressing or squeezing some part of the wheel? I could probably find a bandsaw with a mechanical brake locally and look at it.

I've stopped the bandsaw (after turning the power off) by squeezing the flat of the blade between two pieces of wood but that's not a great method. I'd be happy without an emergency stop, just want to stop the wheels.

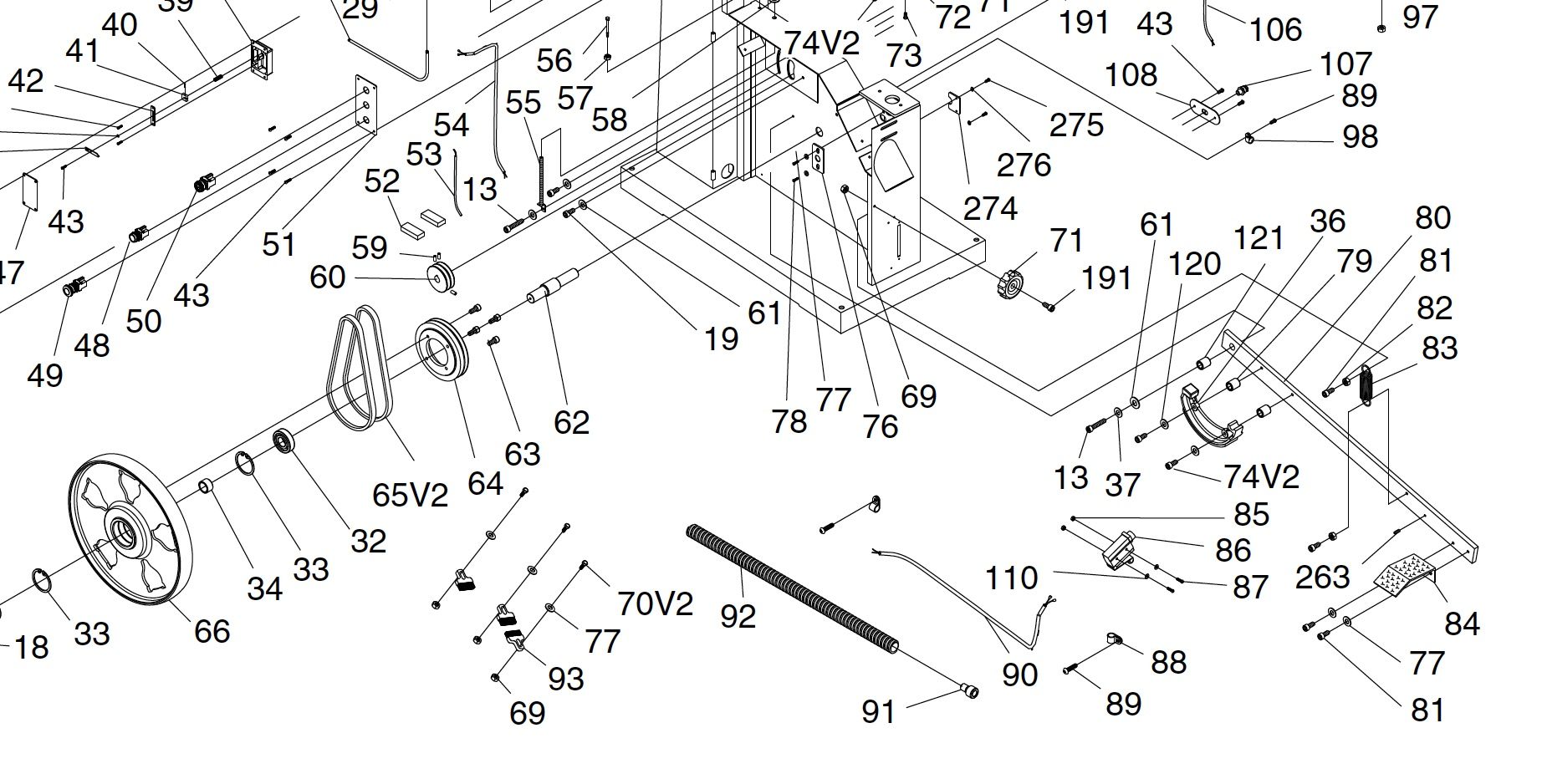

My new Grizzly has a drum brake, part 36.

Thanks. I found the manual for your saw with the part nanes and all which should make things clearer, said it has a magnetic brake. It also states “Use the brake only in emergency situations…” I want something I can use routinely, not just in an emergency. I used a huge bandsaw in the 60’s with a mechanical foot brake we used often for safety, not just for emergencies. That saw had a 20’ long blade and could go for s long time when turned off.

Excellent that the shipping company put in on a larger crate - a total joke trying to move without that. Mine came like it is shown in your photo - imagine someone trying to move that crate with the shoddy base they build - at least they could build a sturdy base and add a few boards for stability. Twisting and dragging works just fine - will not take much effort to uncrate is an upside. Hope all goes good for you in getting ready for service.

On my bandsaw a brake pad simply pushes against the inside of a drum feature (~200 mm diameter) cast into the lower cast iron belt sheave. Nothing terribly exotic beyond a bit of extra material on the sheave and some linkage to connect the foot brake to the friction pad. The pad itself is roughly 20 x 70 mm and appears to be cerametallic. Mine looks more substantial in person than the Grizzly parts list drawing shown here..