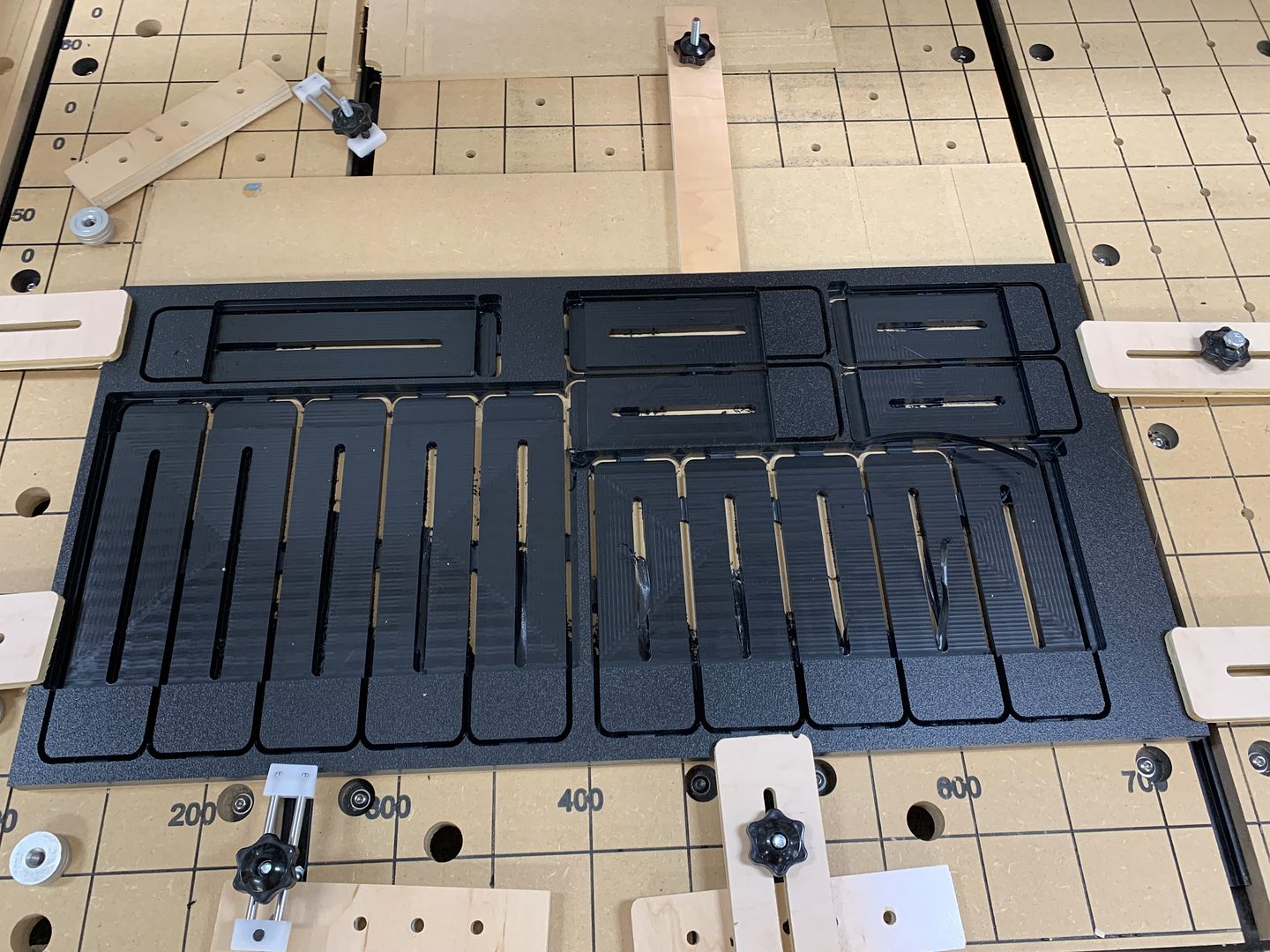

I use “Gator” and “Tiger Claw” clamps from Carbide 3D. The “Tiger Claw” is when I need surfacing clearance. It’s an investment but they work incredibly well and have never slipped on me. My ShopSabre also has a vacuum table, but I use these a lot for all sorts of holding.

Reply With Quote

Reply With Quote