I have a short stroke Hammer K3 slider (wagon is 1250 long). The wagon is used with a reversed Fritz and Frans jig (as the crosscut fence is at the start of the wagon). This pushes against the crosscut fence and locks in place ...

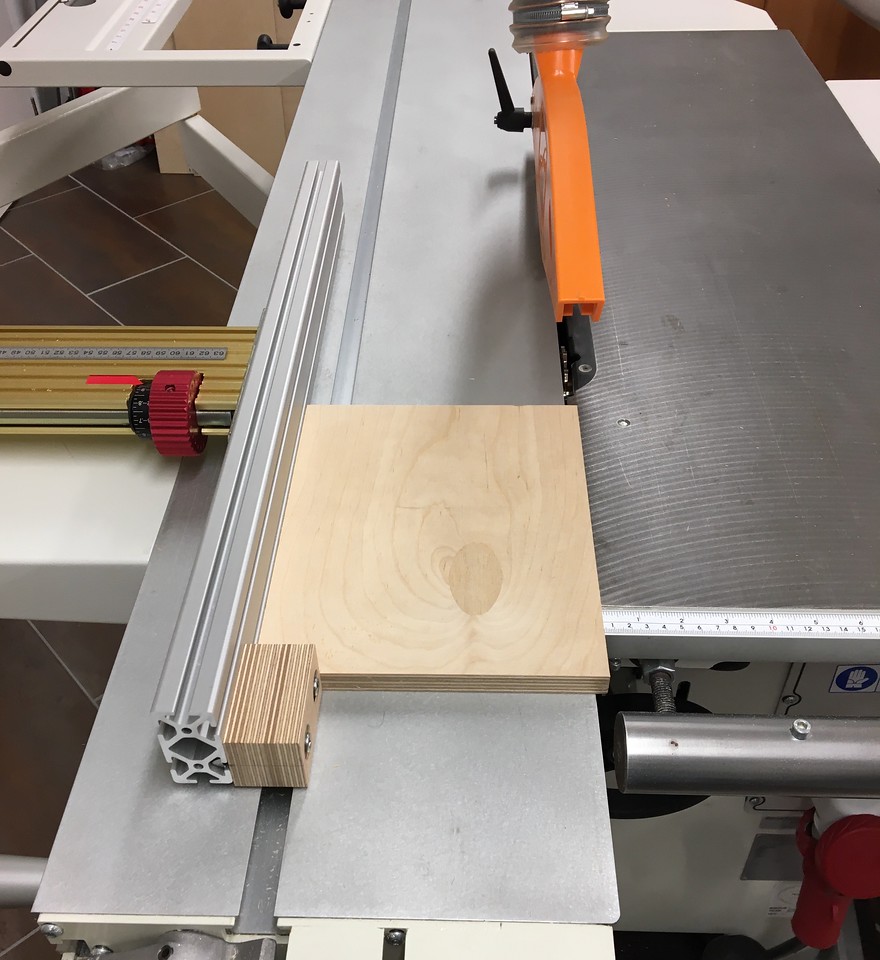

Or I have used a parallel guide, such as this ...

That PG is really quite good in use, but it is a bother at times to bolt to the wagon when needed. What I liked was the one Mike Kreinhop made using an Incra LS25 positioner ...

Two years into Covid and many tools are not available. In the case of the Incra Positioner, it is not available in Australia, and if it was, it would cost $1000 (AUD). So I decided to look elsewhere.

The parts used here were items lying around the workshop. If purchased, there is probably about $100 worth.

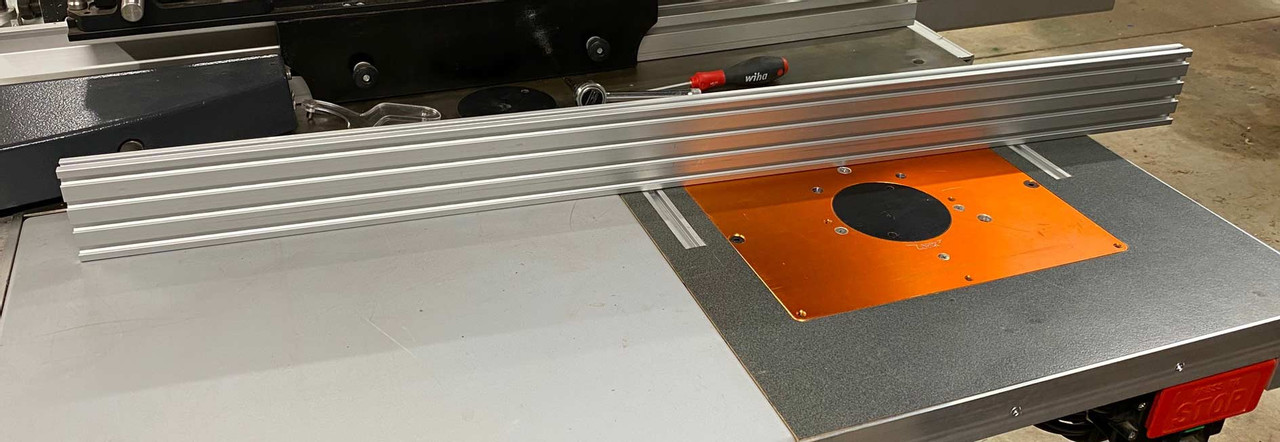

The main component was a 1m length of 8020 aluminium extrusion, identical to the one I used for my router table fence ...

The fence came from an Incra mitre fence (which had been used with the original F&F I made a few years ago, and discarded when the reversed F&F was built).

This is what I came up with ...

The fence along with the stop, which can be used or removed ...

My aim is the use the parallel guide in conjunction with the crosscut fence. The parallel guide is set up square to the blade and, like the stop on the crosscut fence, it can be set at a specific distance.

The maximum setting distance from the blade is 500mm.

The underside of the parallel guide: tracks made of UHMW ...

The rear perspex guides double as a position locater ..

Everything is adjustable. Below, the fence is adjusted for parallel by the side screws ...

Steel angle brackets are used to connect the base to the wagon. The L-bracket on the underside ensures the base is square. This is also adjustable ...

.jpg)

Reply With Quote

Reply With Quote

. Seriously, very nice parallel solution!

. Seriously, very nice parallel solution!