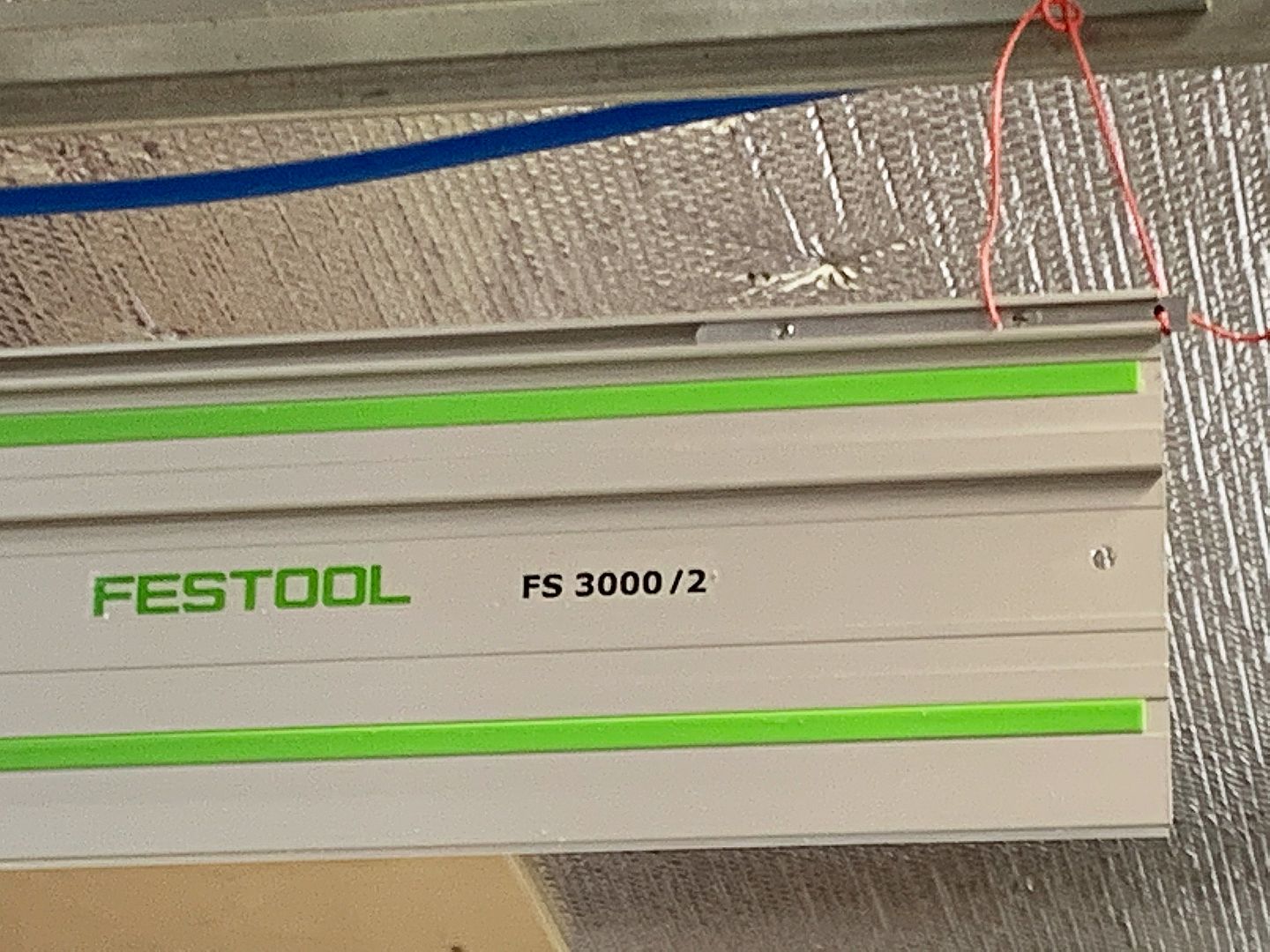

I have two long tracks for my track saw, along with short ones. I now hang them on a central post in my shop, but also use the post for a lot of other items and they are in the way. I am looking for an alternate place to hang the long ones. They are 108", if memory serves.

I saw that someone stored them sideways on the rollup garage door in a You Tube video, and it seemed like a good place.

If anyone has done that I would like to see pics of the brackets you used. I have several ideas, but don't want to reinvent the wheel.

Any other good ideas for storage are welcome also.

I cannot hang them horizontally above windows or any where where I need to reach up high. Pushing 80, and supposed to stay off ladders, and both rotator cuffs are shot. No wall space left.

Thanks,

Reply With Quote

Reply With Quote

). Allowed me to use some space that wasn't usable for much else.

). Allowed me to use some space that wasn't usable for much else.