Hi all - first time posting here (I think)...

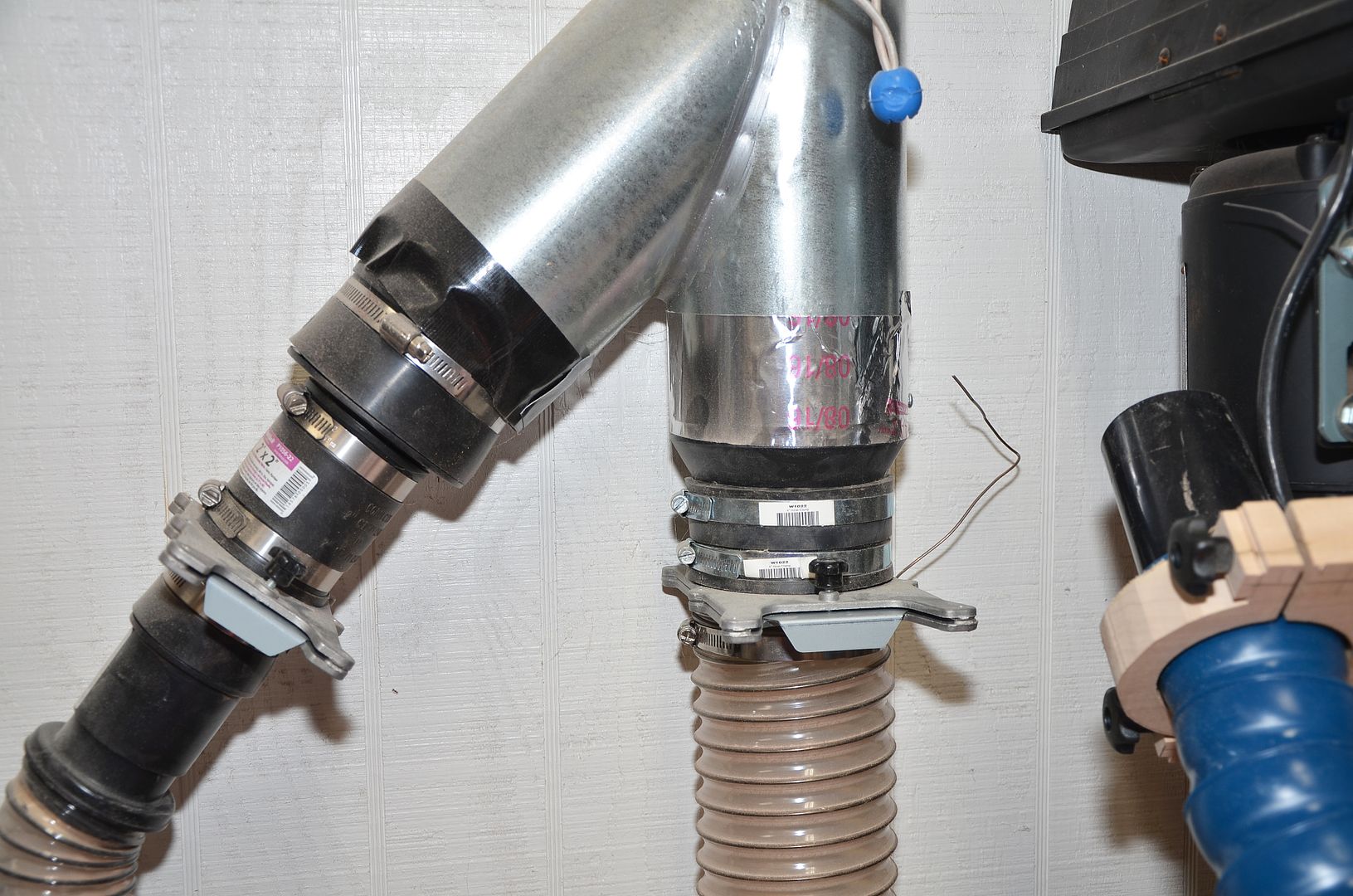

I'm planning to change my Jet 2HP single-stage collector into a 2-stage, by relocating the motor/impeller unit on the wall, ducting the 6" port down to the bag unit, which will be modified into a thein baffle with a 6" fitting. That part is pretty straightforward to me.

What I'm not sure of is how to handle the 5" port on the bag unit (which will be repurposed as the main baffle input). Given that 5" ducting & fittings are far less common than 4" and even 6", I'd like to use one of those sizes to run to my tablesaw, router table, jointer, and planer. None of those tools will be used simultaneously, so I don't need a ton of airflow, but I want the system to be fairly effective in controlling dust in my 440 sq ft garage shop.

If I adapt up to 6", will that cause any issues? I assume that it has to be better than adapting down to 4", but I don't know if creating more space causes more problems than it's worth.

Thanks in advance for any help!

Reply With Quote

Reply With Quote

)

)