I know the right answer is, “what tool do you own?” but I’ll ask anyway because I am redoing my workshop and splurging on better tools.

I have a Rigid miter saw because I didn’t know any better at the time. It is nice for some jobs but it has a good 1/8 inch deflection if I put any pressure left or right. I have a saw stop with Incra miter gauge and Incra sled. Needless to say, cutting four legs to size on table saw is going to be way more accurate so that’s what I thought was best. I think compared to a Rigid miter saw that answer is correct.

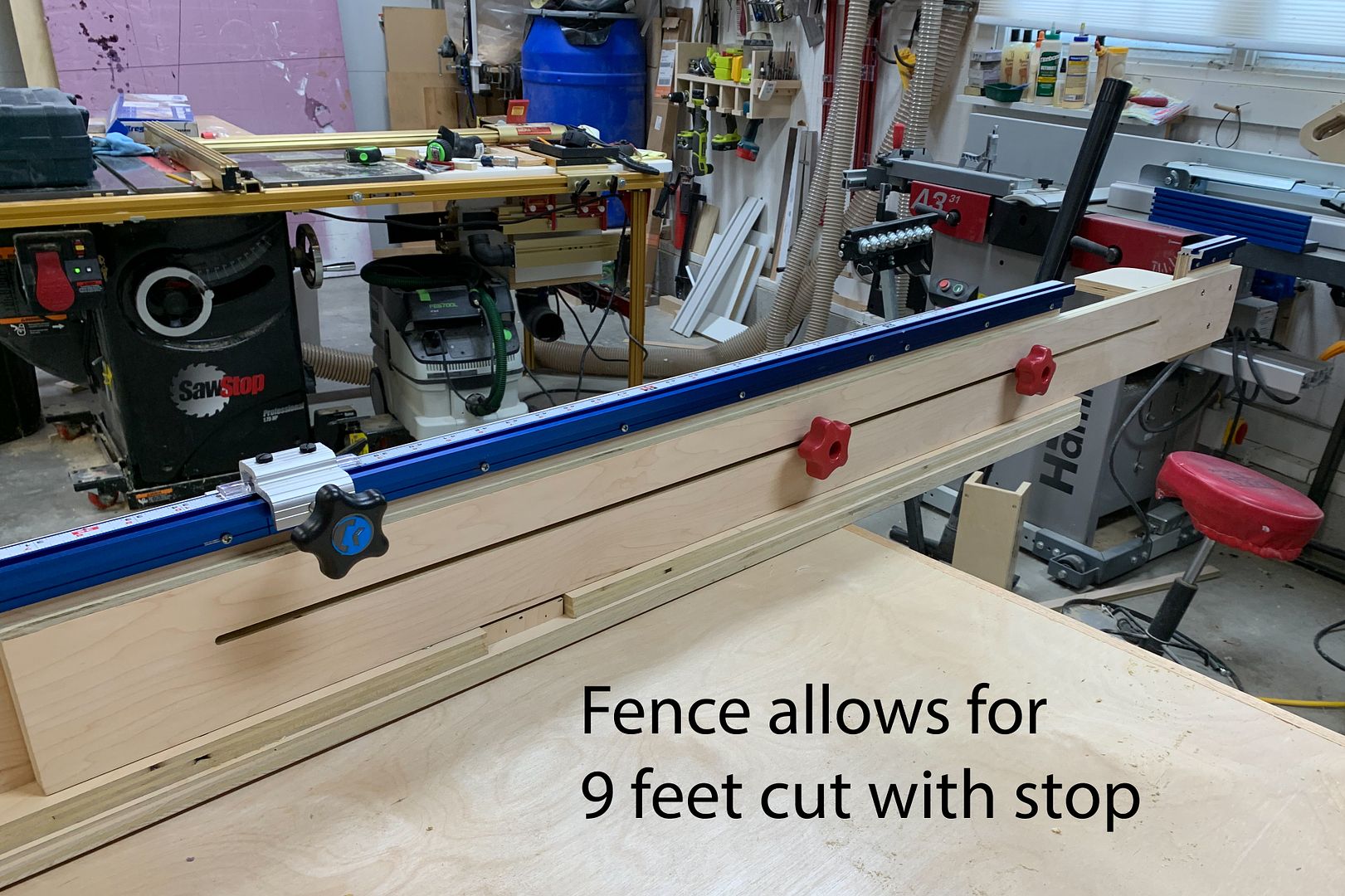

But what if we were talking about a Festool miter saw in a long station with cabinets beneath and stops to the left and right?

At that point would you cut to final length on the miter saw or still use the table saw? Would you use the table saw for short pieces and the miter for long? Would you say don’t use either, use the high end track saw?

I’d think the stationary nature of the miter saw would be best, but the Rigid kind of has me wary.

as always, thanks in advance for the excellent help I know I’ll be getting, and please feel free to give answers to my unasked questions.

Reply With Quote

Reply With Quote