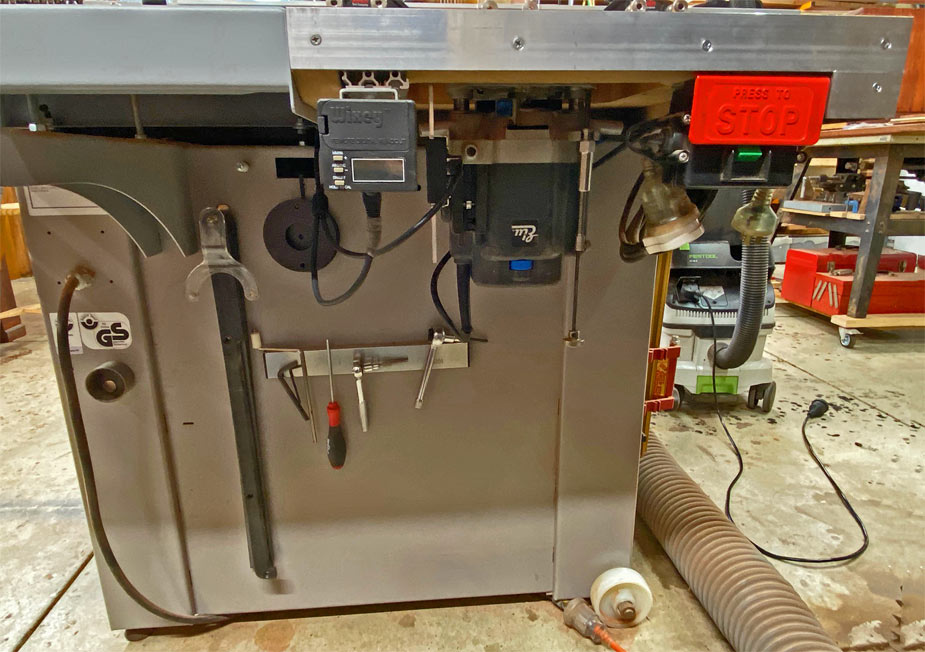

That "rotary adjuster" is a Deulen Safety Fence. It was a 2015 WOOD Innov8Award winner, and I bought one at the time. It is incredibly handy/safer for ripping narrow pieces on the table saw. That being said, sadly I was one of a tiny number of people who bought them, and the inventor had to stop making them.

Interestingly, I e-mailed him recently out of the blue, and he is working on an upgraded version that sounds motorized with a stepper motor and improved. Could be awesome. I very much like his original one. It does make a dodgy operation quite safe, and allows me to use my overhead dust guard more often on narrow pieces. I would seriously consider it when that comes out.

I have no financial relationship with the company. Just one of the few who bought one way back.

- After I ask a stranger if I can pet their dog and they say yes, I like to respond, "I'll keep that in mind" and walk off

- It's above my pay grade. Mongo only pawn in game of life.

Reply With Quote

Reply With Quote