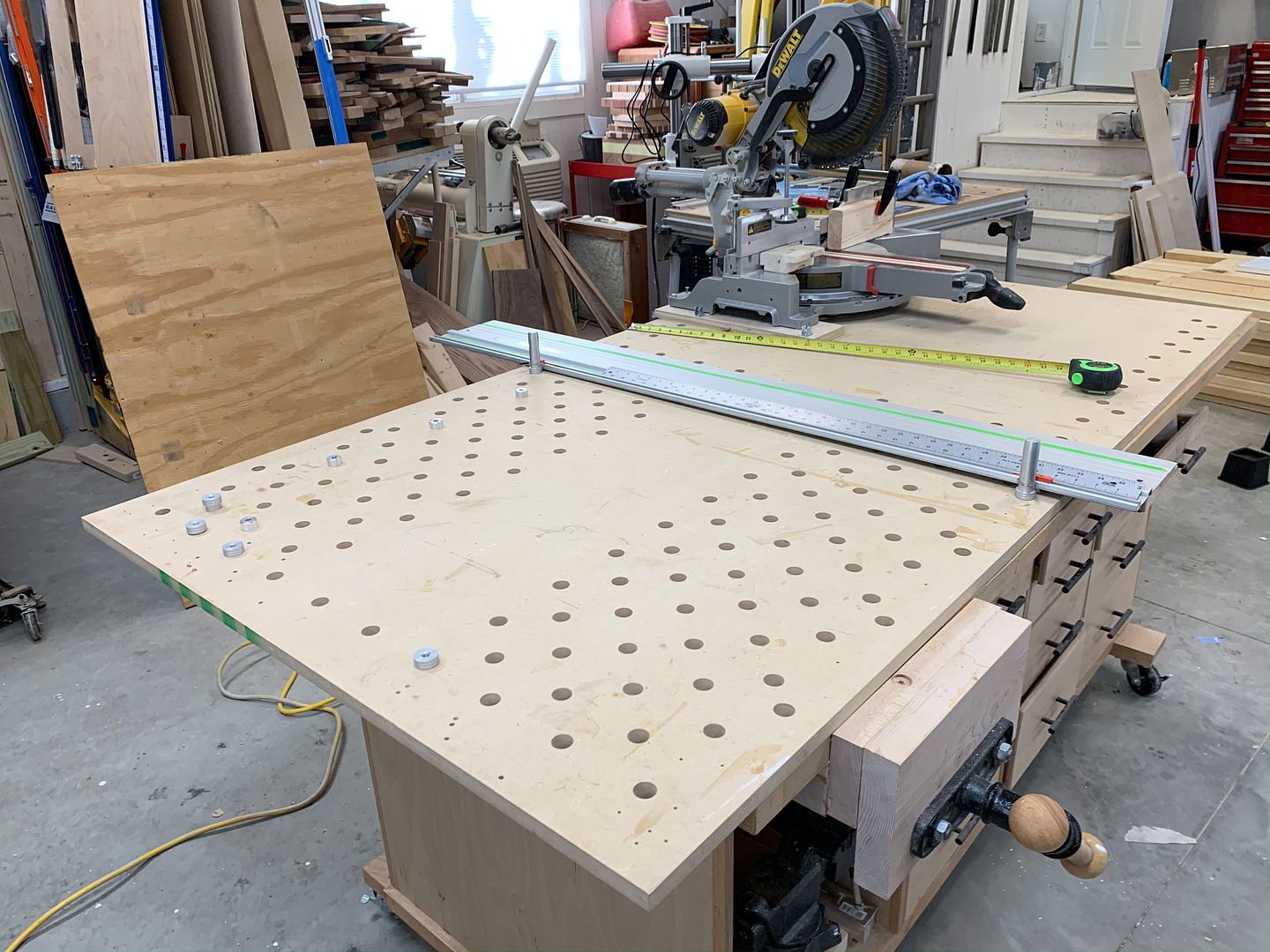

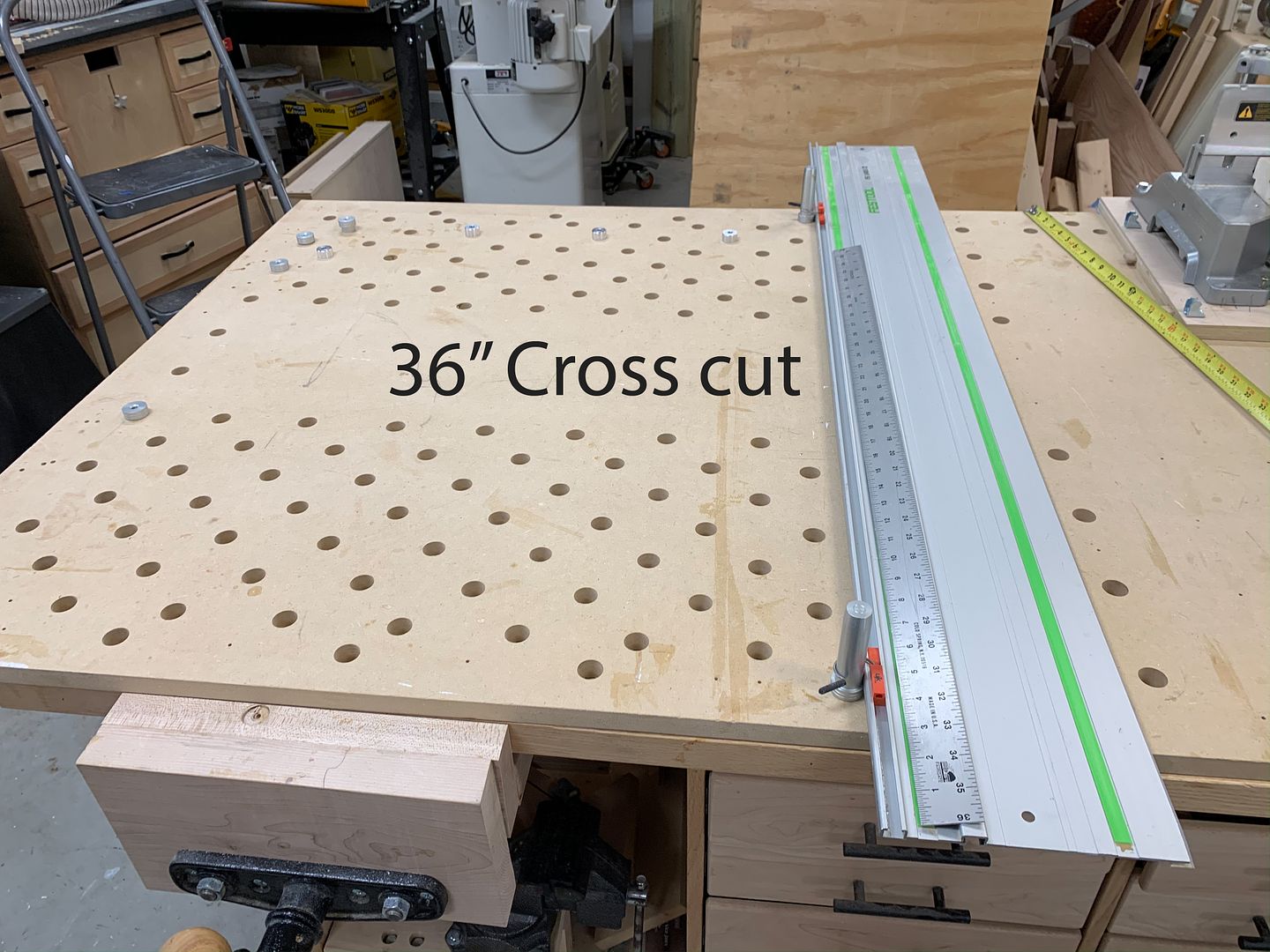

While Chri's (wonderful) implementation is certainly expansive, what's most important about it is that it shows the possibilities for integrating the system into your woodworking workflow...and they work on a smaller scale, too.

I honestly caution about "I'm only a hobbyist" thing. Doing something for personal enjoyment doesn't reduce the value of setting things up so that your shop works for you and makes the activity even more enjoyable. That doesn't require spending huge amounts of money; rather, it requires being creative and being willing to consider and embrace different ways of accomplishing tasks. The "grid" is a good example of that. Make it work for you in a size that's reasonable for your available space.  I can think of a number of projects I did over the years, especially early on, that would have benefitted from the things I've found along the way, many of which from folks here at SMC.

I can think of a number of projects I did over the years, especially early on, that would have benefitted from the things I've found along the way, many of which from folks here at SMC.

--

The most expensive tool is the one you buy "cheaply" and often...

Reply With Quote

Reply With Quote

I can think of a number of projects I did over the years, especially early on, that would have benefitted from the things I've found along the way, many of which from folks here at SMC.

I can think of a number of projects I did over the years, especially early on, that would have benefitted from the things I've found along the way, many of which from folks here at SMC.