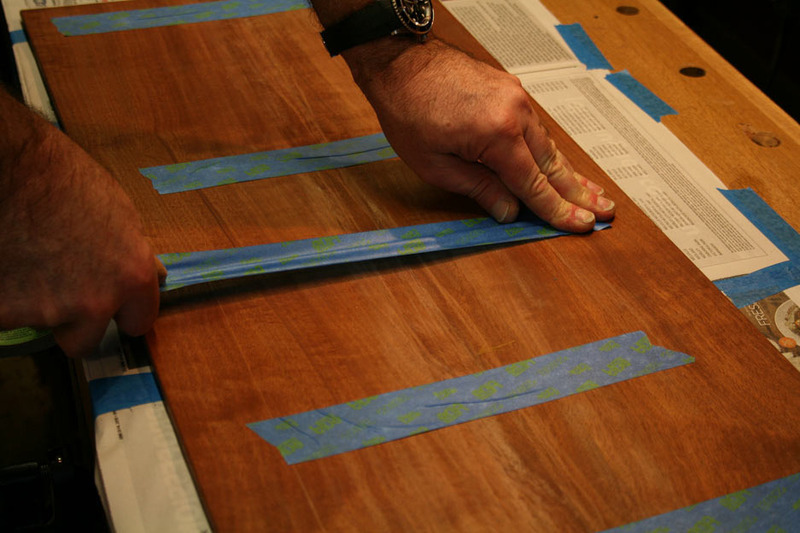

I'm getting started on the chest of drawers from "The Joiner and Cabinet Maker", right now I'm still working on stock prep before gluing up my panels for the case. I've always found clamping and glue ups to be the thing I enjoy least in woodworking, so learning about rub joints as a way to do long edge joints without clamps has been intriguing. If I can make the process more enjoyable, why not? I'm doing this as a hobby after all.

I've done a shorter practice rub joint with Titebond III on some white pine that I think came out pretty good (the glue line came out thicker than with clamped joints, but it's still acceptably thin), and I'm pretty sure with a bit more practice I could make an even better joint.

What glues are really best for rub joints? I know these were traditionally done with hot hide glue (I've got a small package to try out on the way in the mail), and most of the sources I've seen say you can do rub joints with PVA glues, but it's really recommend to clamp joints with PVA glues... On the other hand, watching WoodbyWright's glue testing videos on youtube, it seems like hide glue is definitely weaker, and has poorer gap filling performance than a good quality PVA glue like Titebond III. Maybe that doesn't matter anyway since hot hide glue was used for rub joints for centuries.

I'm interested to hear what you folks on the creek have to say!

Reply With Quote

Reply With Quote