Originally Posted by

Alan Lightstone

Ok, now the second issue.

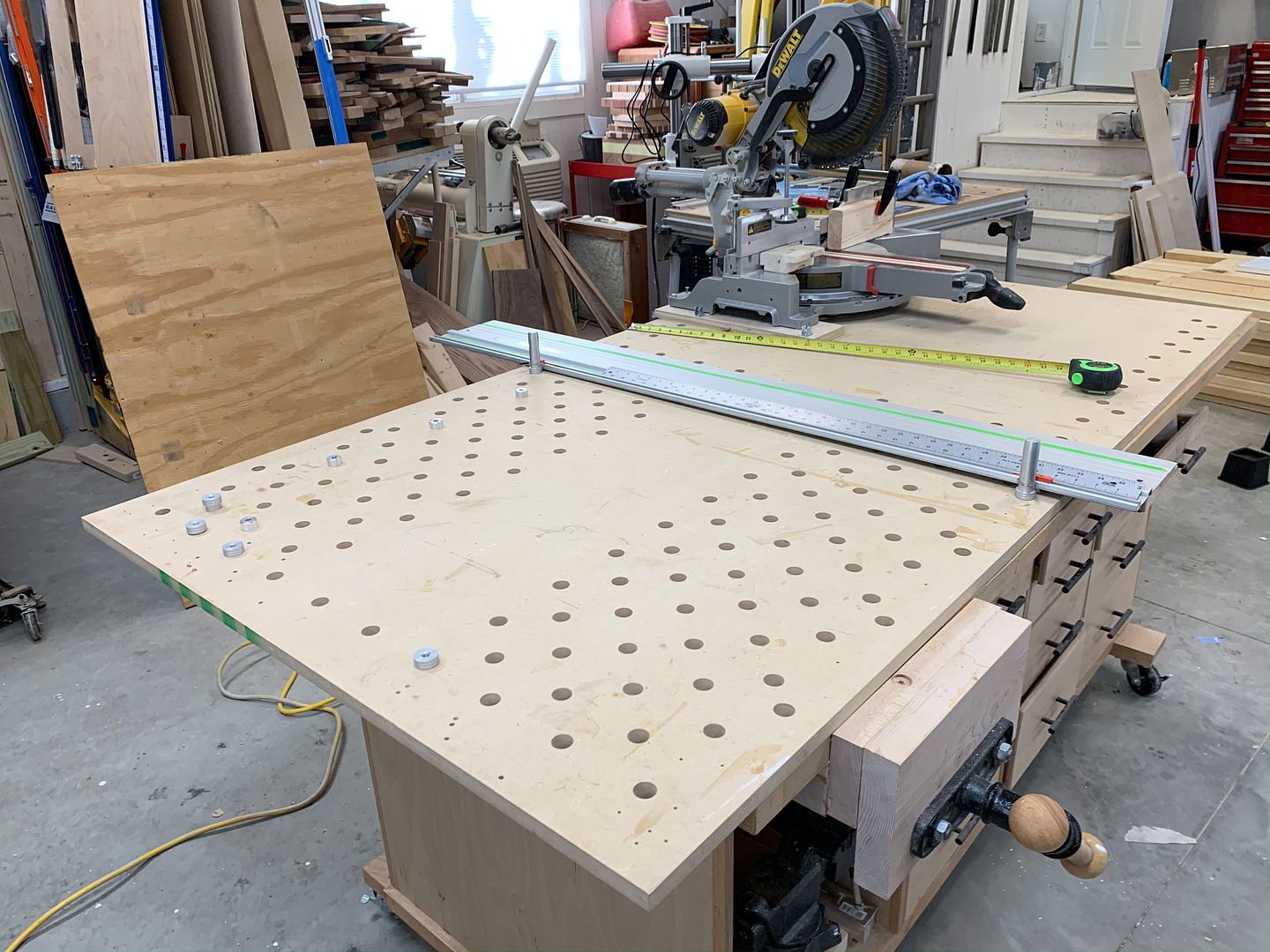

Looking at materials to build the top, or perhaps buy a top and modify it to size.

The best size I think considering the cabinet base below, and to allow sufficient space on the sides is 73" x 32". Of course if I choose to buy one, that extra inch from 72" might be a non-starter and I might have to stick to 72".

My questions are (and I know some of this is covered by some old threads which I have looked for):

1.) Is a 1-1/2" top thick enough for dogs? I know that it's probably too thin for a holdfast (is that true), but I haven't ever used one.

My opinion, you don't need a top thicker than 3/4" to use bench dogs. It=f you want to use clamps that go through the dog holes, you can't go thicker or you can't get the clamp in.

2.) I was planning to make holes every 4", but the Woodpecker jig I have had for this for about a year, makes the holes every 3-3/4" on center. Weird. It's about 96mm, so it's not a convenient metric spacing either. Weird.

Metric dogs are set at 96mm, 3 x 32mm, that's where that spacing comes in

3.) I was planning on using hardwoods. Still not sure which one. Suggestions? I don't know if I can easily get Red Beech, so perhaps something else (? Maple).

I use plywood and 3/4" edgeband solid wood. Do you need this to be a piece of furniture or a workbench?

5.) Is 1-1/2" to thin to build or buy an end-vise, and have it work?

I don't think so, but you always reinforce it underneath where necessary.

6.) Advantages / Disadvantages for making an end-grain butcher block top vs just using long face grain pieces.

See answer to #3.

Reply With Quote

Reply With Quote