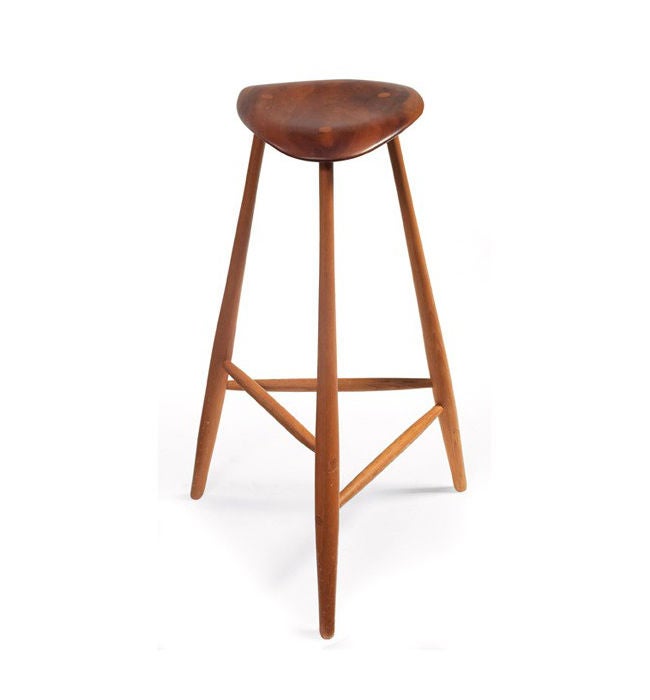

I am in the process of building a number of stools (based on Wharton Esherick's famous design). The seats are shaped and the mortices cut. Now I need to build the legs.

The slider (Hammer K3 short stroke), using an F&F jig, was great for breaking down a wide Hard Maple board roughly 2" thick. The legs were ti be turned from 40mm square sections. This was completed using this simple fixture: a length of veneered ply with two hold downs and a side stop (this was screwed on for here, but I would like to make up a sliding version). This fixture enabled rapid setting up of 40x40mm sides ...

Leg section positioned ...

Ripping underway ...

Now I wanted to bevel the sides in preparation for the lathe and turning cylinders.

I could not do it! The blade leans the wrong way to do this (right tilt) ..

And there is too little registration to clamp the leg to the slider.

So how would you do this? (I ended up using a scrub plane - painless).

Regards from Perth

Derek

Reply With Quote

Reply With Quote

The bandsaw can also be employed for this work and then do your cleanup with planes as you will anyway.

The bandsaw can also be employed for this work and then do your cleanup with planes as you will anyway.