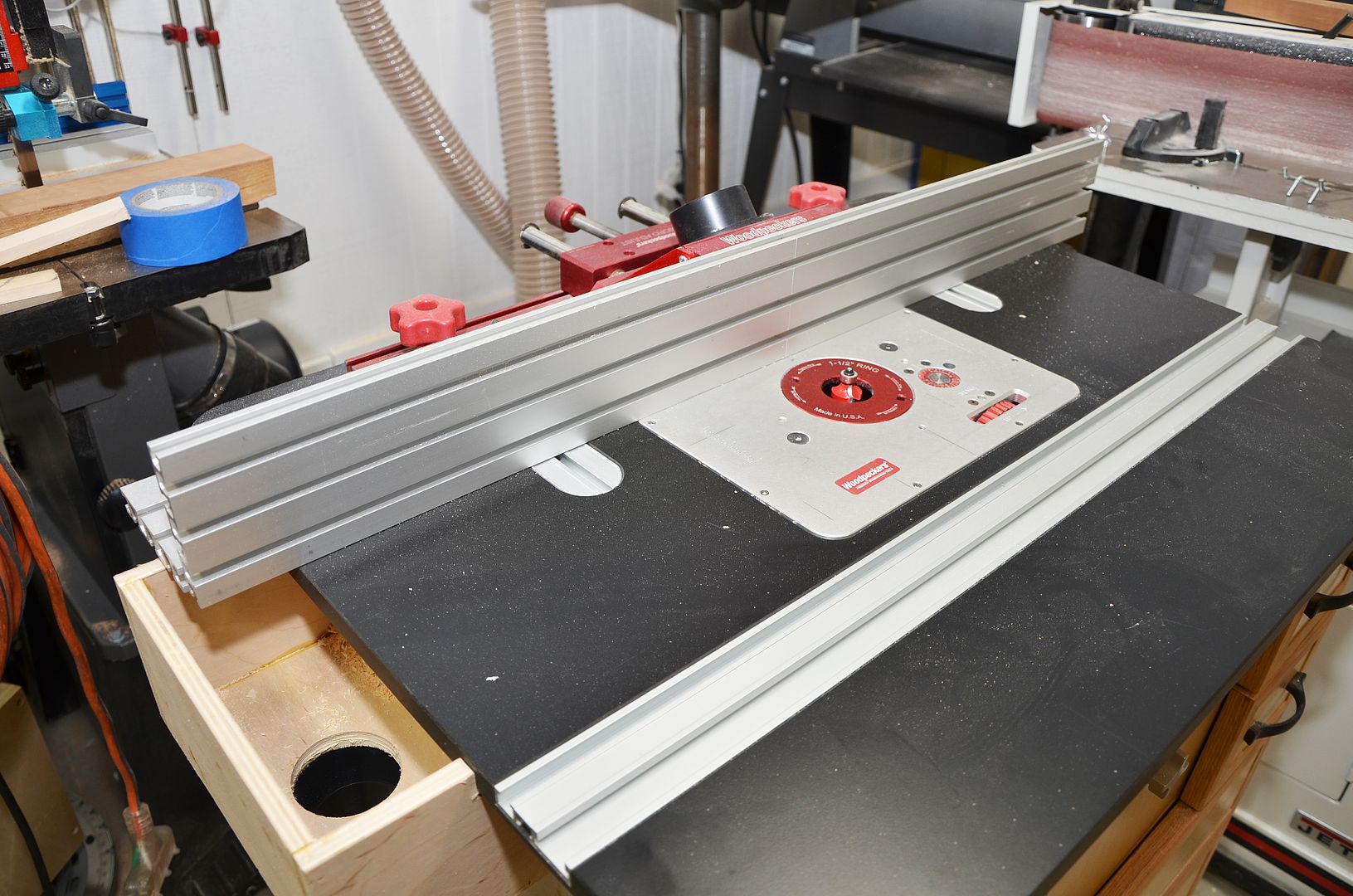

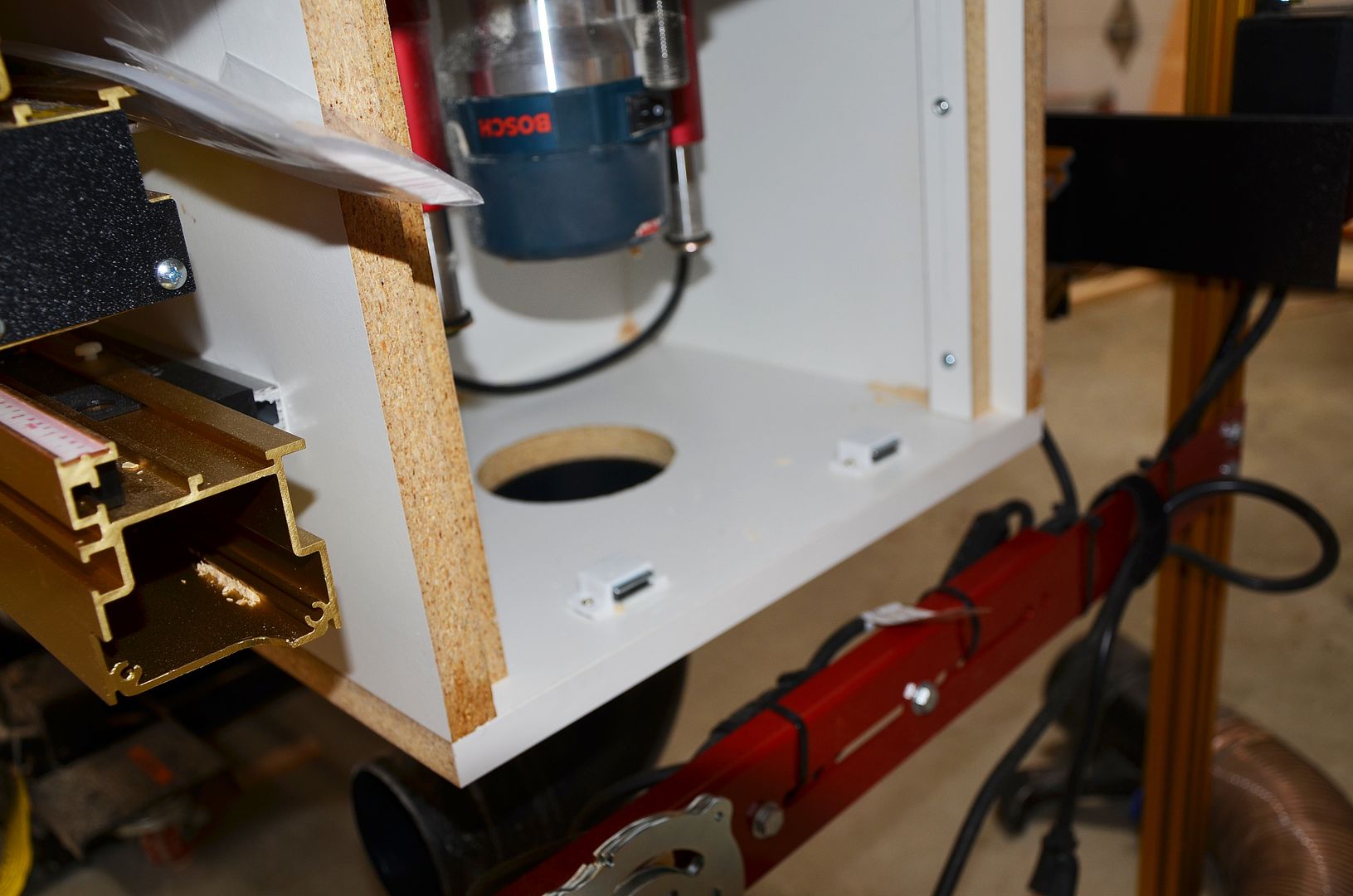

Hello, I have been using a Bench Dog full size router table for years with a Craftsman 16 gallon 5 HP shop vac. It actually does pretty good. I would like to upgrade to a 4 inch for the router enclosure and branch it off to 2 1/2 on the fence and move up to a 1 1/2 HP Delta 2 bag dust collector

Any thoughts on this. If you have done this photos, Please.

Thanks in advance, Kevin

Reply With Quote

Reply With Quote