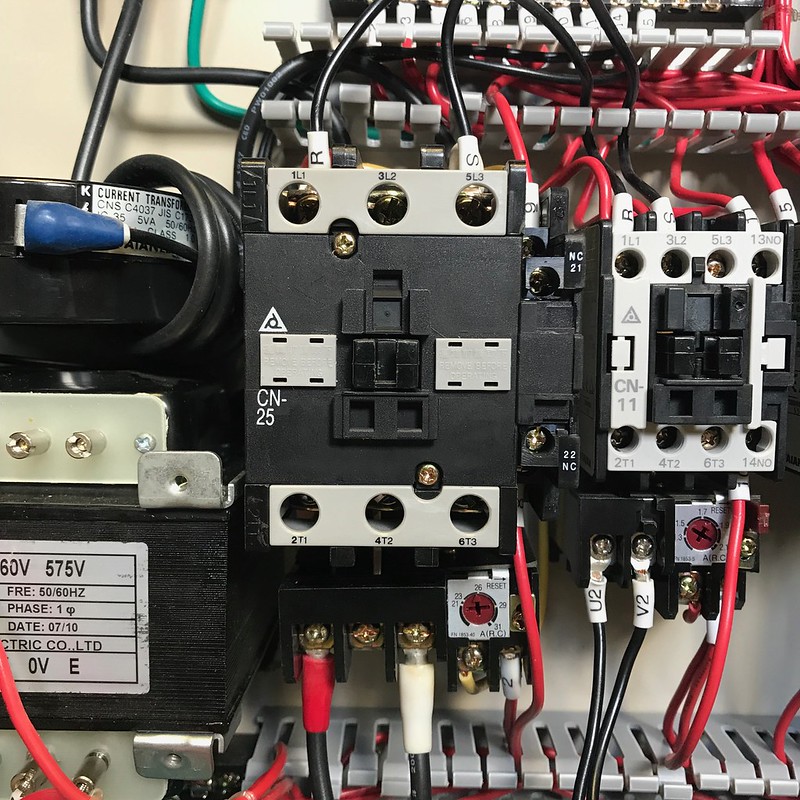

According to the schematic if fuse 1 is removed and it runs then M1 AND M2 are either bypassed or the contacts are stuck. I can't see both of them going bad at the same time. Normally when they go bad they don't work. I've only seen one out of more than a hundred I've had to replace over the years at work that had the contacts welded closed. That was due to a motor that burnt up and the current draw far exceeded what the contacts could handle. The 'square' box on top of the contactor was stuck in the down position. The way contactors are made is the spring is under the contact points. So if they are fused shut the spring is compressed.

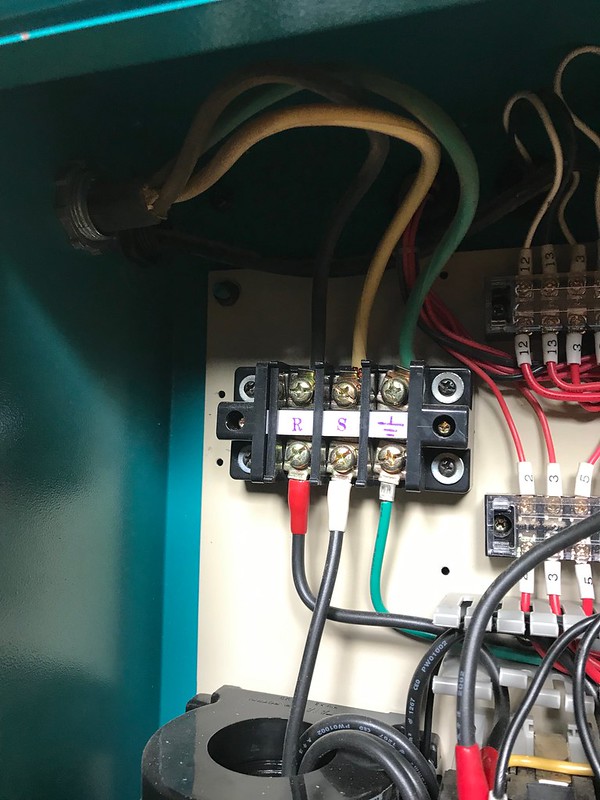

Knowing this I just looked at the picture of the wiring and it looks like T1 and T2 look to be on the same side of the contactors and L1 and L2. If so that's your problem. They should be on opposite sides of the contactors.

Reply With Quote

Reply With Quote