I have the Incra 1000HD, which is very good, but for 99% of cross cutting, I use a cross cut sled. The Incra 1000HD comes out when I need to cut an angle on the end of a piece of wood.

The Incra system comes with a full length front and rear rail, neither are carrying much load. I was concerned about the 4 places the rails attach to the cast iron table, but you can buy extra L brackets ($16) and beef that up to be pretty much the same mount points as the L channel of the OEM rail mount.

I did find out, the difference between the 32" and the 52" Incra system is just the table rails being 20" longer, The arm for the TS-LS positioner is the same length, so to do a wider rip cut, you have to move the base of the TS-LS positioner. Not a huge deal as you would have a set of reference stops for each position.

I looked it this, as I figured I could get about a 42" rip comfortably where my saw sits now. But I can actually achieve this with what I currently have as the central arm is the same for both lengths.

Personally, I would skip the SawStop outfeed table and make you own. The Incra rails offer a much easier attachment point than the OEM rear rail.

For Dust Collection, I bought a mobile dust collector, but for less than $100, I ran Schedule 20 6" sewar pipe to a couple of drops with blast gates. When I moved house I removed it. Being lightweight, I just had to sparkle a few mount holes.

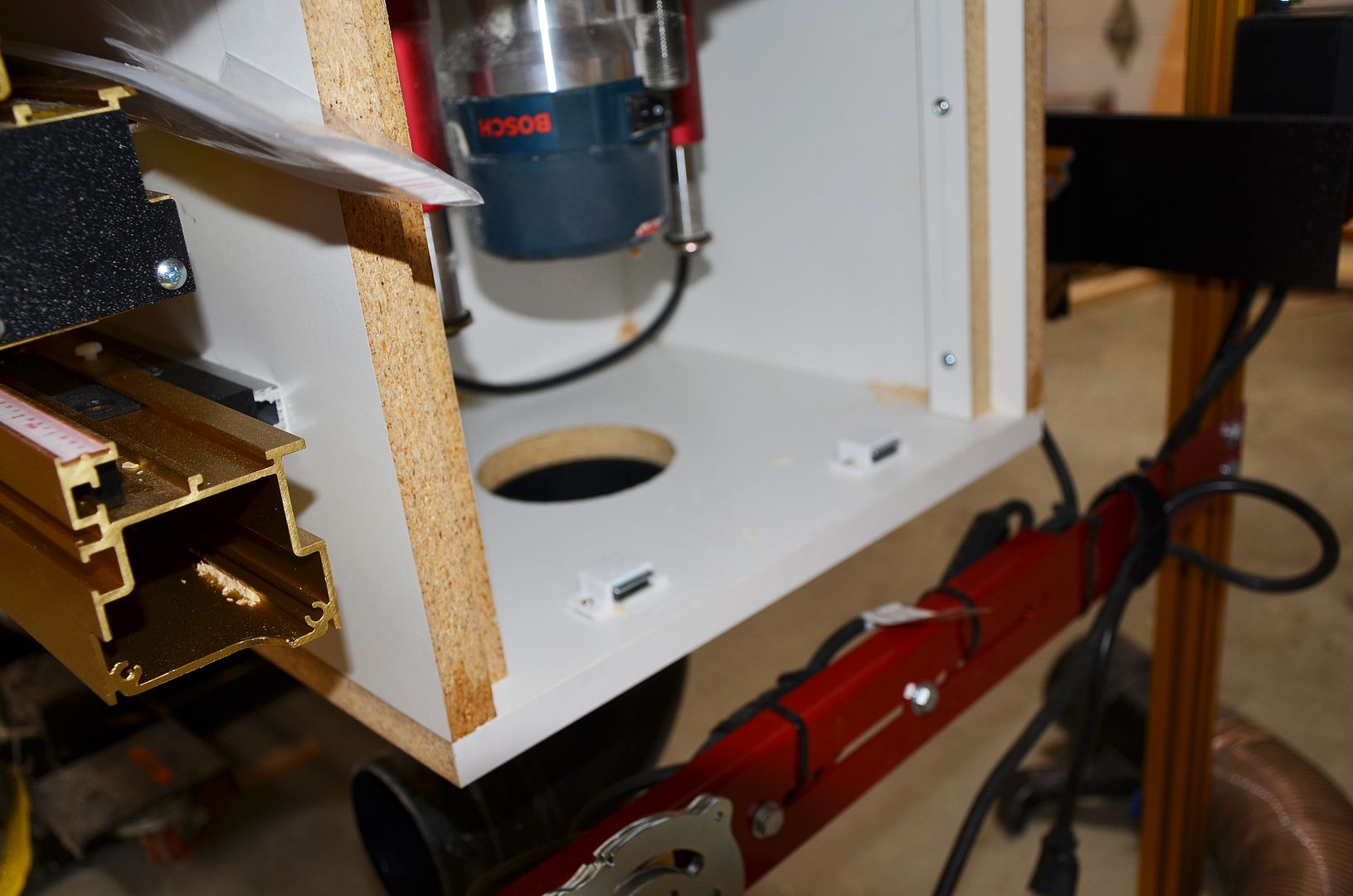

One thing you mentioned was using the router table, if I understand it, moving work parallel to the front rail, so you would have the support of the entire table.

My thought of this, you would have a vey short infeed support to the router bit and a massive support on the outfeed side. Using it right end, as in my video, you get reasonable support for both infeed and outfeed, but you could also slide your folding outfeed, along the fence rail, to provide extra table support and in theory, you could make a mini folding outfeed table that you could attach to the front rail when needed. You can see in my video, my current outfeed table is on casters and I actually rolled it down to provide extra infeed support for the long peices I was cutting.

Reply With Quote

Reply With Quote

The incra system is so versatile and useful, and with your technical expertise, you will master it in short time... for exact cuts and repeatability, it cant be beat. But for work that is not super critical

The incra system is so versatile and useful, and with your technical expertise, you will master it in short time... for exact cuts and repeatability, it cant be beat. But for work that is not super critical