I got this Combo Shaper Cutter Head about 6 months ago and other than a quick inspection, haven't done anything with it.

I've never used my Shaper yet, so this is a very rookie question.

I want to use this head to make a Tenon and will cut the bottom side of the Tenon and then flip the wood and repeat.

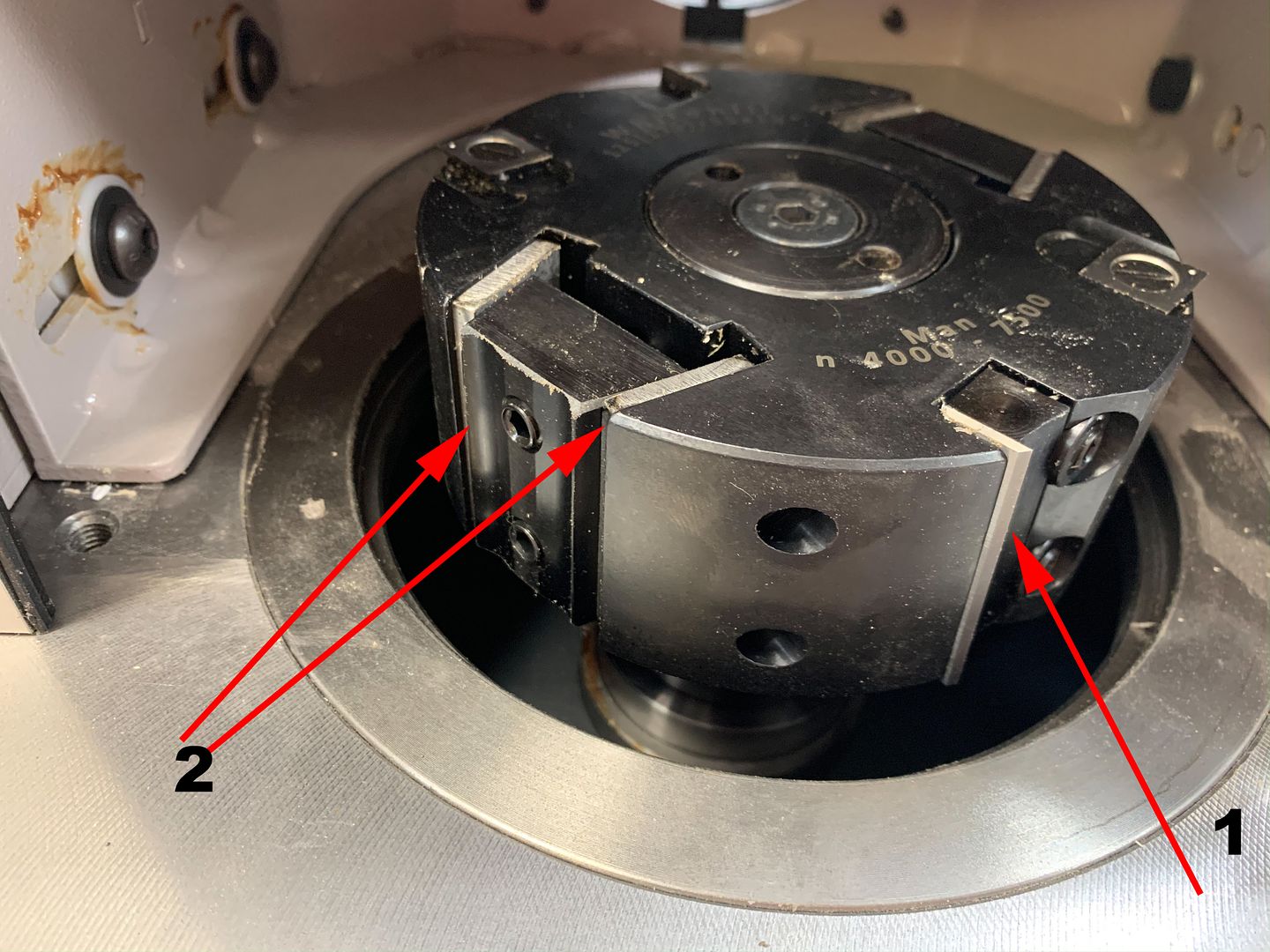

When I ordered it, I ordered about 6 other profile blades and the limiters to go in position '2' in the photo below.

As you can see, there are blanks installed in these spots currently. I expected to replace these with a couple of straight blades, but looked through all the blades I had and then discovered I don't have any straight blades. At which point I noticed blades in position '1, which are set at about a 15 degree angle from vertical.

I assume these are my straight/rabbiting blades.

(I would have called Whitehill, but I believe they are closed due to Covid-19)

Thanks

Reply With Quote

Reply With Quote