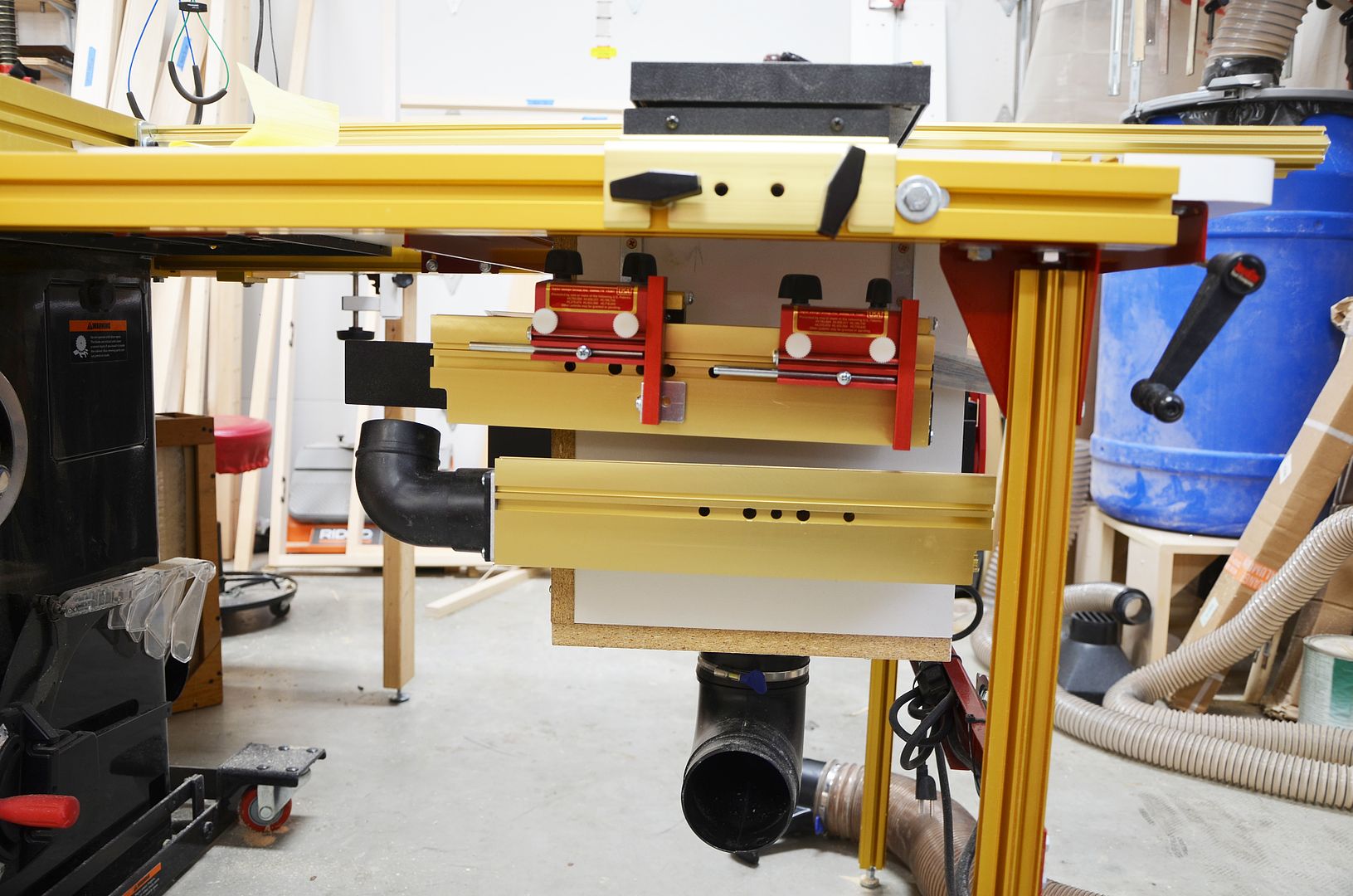

How do people store the common tools used for your table saw. My 66 has an extension table but it has a router in it with a dust "bucket". If I make something it has to work around it leaving me enough room to access it if I need to remove it. My saw is on a mobile base with out the extension but I could add one if needed.

I've been bouncing around with ideas from just putting hooks on the underside of the fence rail in the front to making something thin that can slide out (like a pull out broom cabinet). I don't want something that's too cumbersome though. Simple always seams better in my shop. I've even thought of making something complicated that would include dust extraction for the router and multiple drawers to store saw blades and what not but I really don't think there's going to be that much stuff and since it's mobile I'm not sure if the added bulk will be more problematic than helpful.

Reply With Quote

Reply With Quote