Considering this miter gauge but I have a real use question for real life users

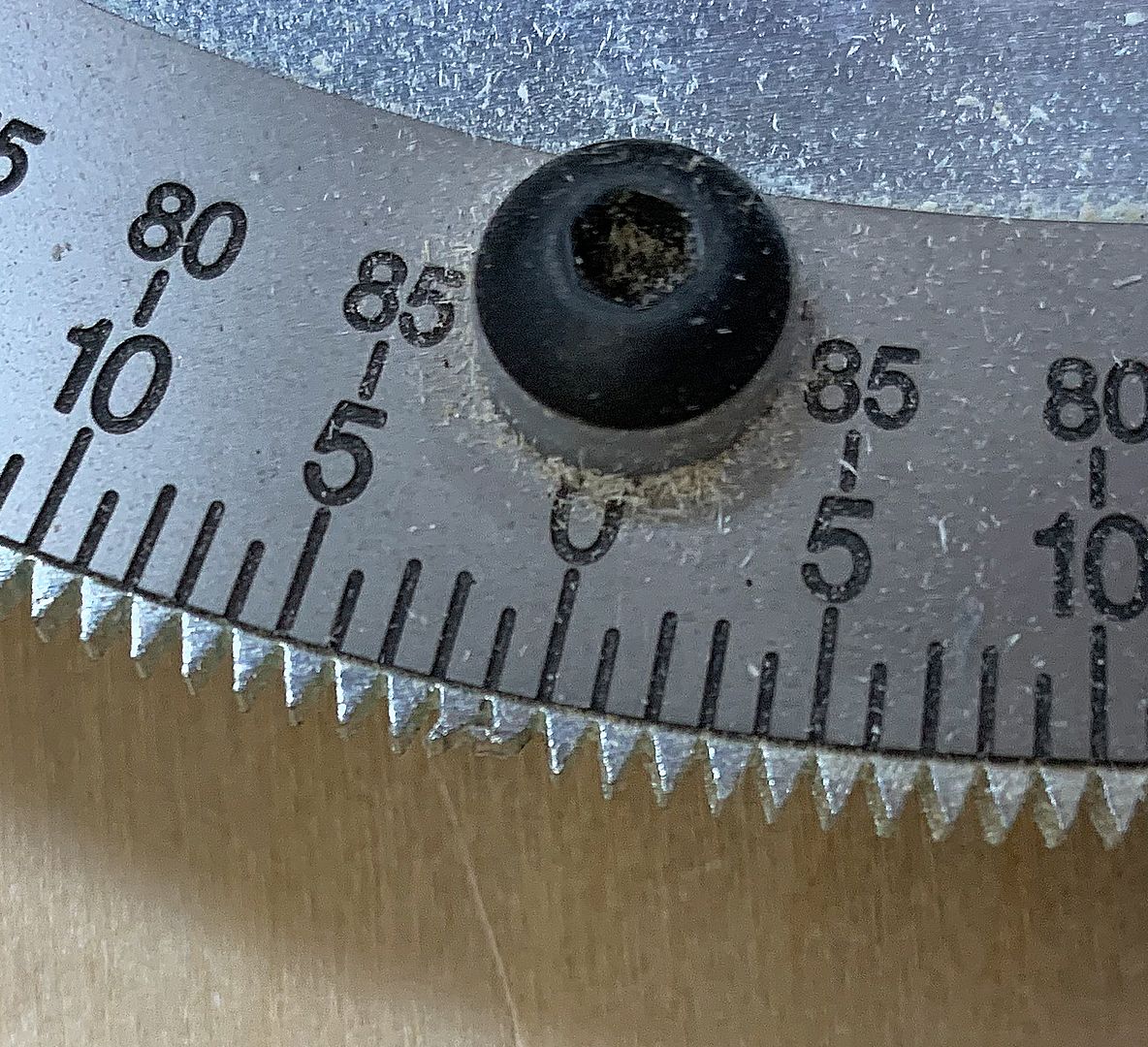

The videos and specs seem to universally love this tool but as I look at the vernier cursor area it looks fragile to me sticking out like it does.

p_miter1000hd_body1.png

Has anyone experienced issues with that?

I have a part time shop with safe storage but it's not full time for wood working shop and a smaller Bosch job site saw

Reply With Quote

Reply With Quote