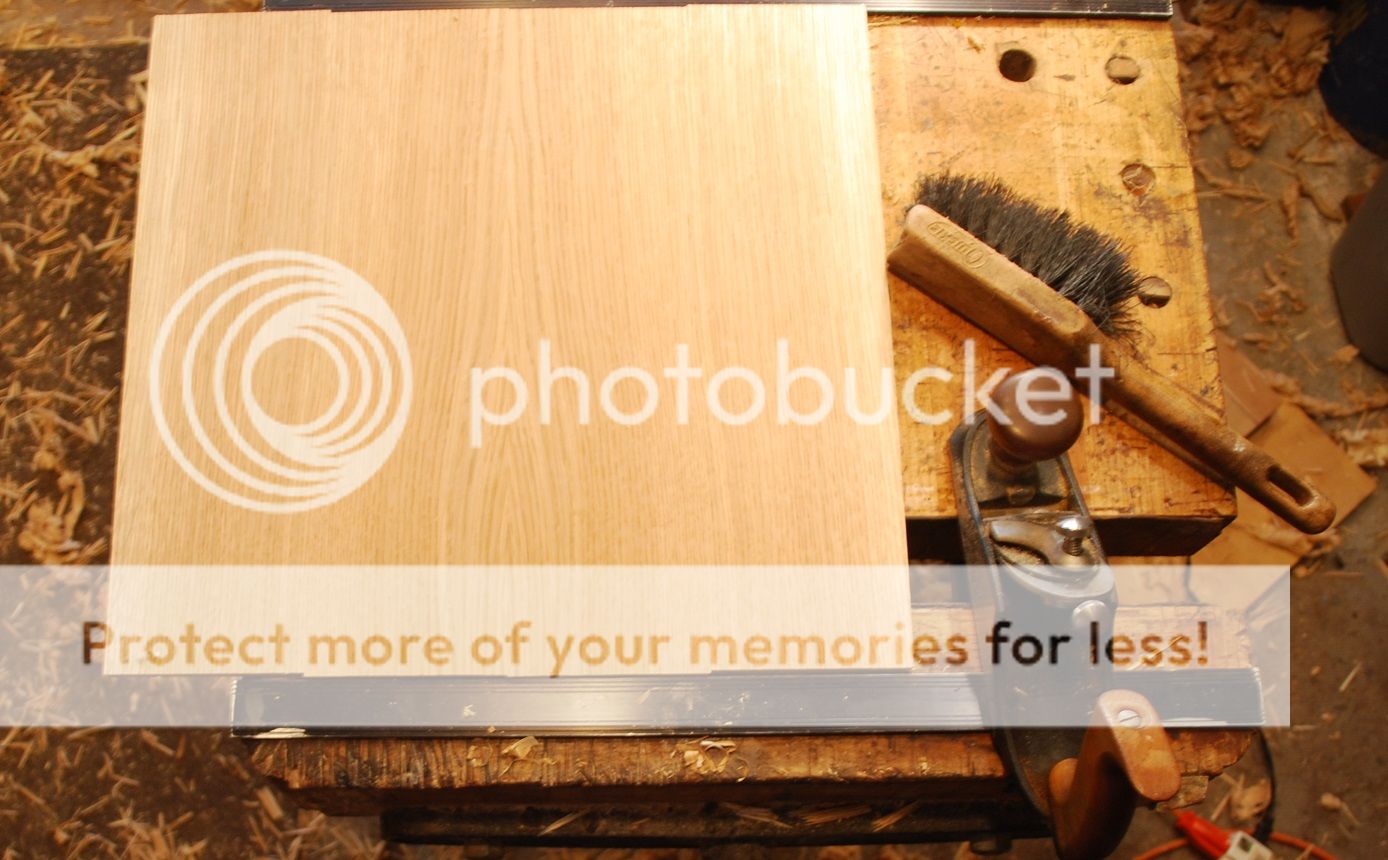

Here are all the panel glue ups spread across every available horizontal surface in the shop.

Grain match results after glue up and initial panel surfacing. I like to rough panel surfacing before sawing to final dimensions so that any spelching resulting from cross grain planing is sawing off in final dimensioning.

Given I don’t have a table saw, the panel gauge is essential tool for ripping panels to width parallel edges. Earlier versions of my shop made panel gauge is had cutting blades, but now I can’t see those layout marks so easily so panel gauge now as 9 mm wide mechanical pencil.

It’s always interesting to me how much my power tool woodworking friends are surprised/impressed with accuracy of dimensioning glued up panels that’s easily achieved with well-tuned hand saws.

LV shooting plane is my most expensive hand tool splurge and for me worth every penny – performs critically important, fundamental dimensioning tasks exceptionally well.

Final check is do all the complementary carcass pieces look the same.

Here’s the layout for the large carcass finger joints characteristic of the Greene & Greene style, and bevel on the edge of the finger joints. For me easier to plane the bevel with block plane prior to cutting the joints.

Reply With Quote

Reply With Quote