I am building some 8/12, 16' trusses for my last wooden building on the place to help "fire harden" the structure. My shop is basically a 30x30 with a 4x14 corner bump out for the big overhead door. Pretty much everything in the place is mobile and that is good and bad. Since putting the place up in '15 I have been so busy in turning out assorted projects for my wife and my daughters that I have not gotten the place really set up and the mobility inevitably leads to clutter. I do clutter very well and it is beginning to drive me nuts. A 16' truss points out these issues really well. The 34' wall has an overhead door on either end on adjacent walls and I want to build a permanent place to dimension lumber. I could go end to end, but think that would be excessive for my use. These 16's are the longest boards I've had to deal with. Most of my work is tables, stairs, doors, furniture, etc.

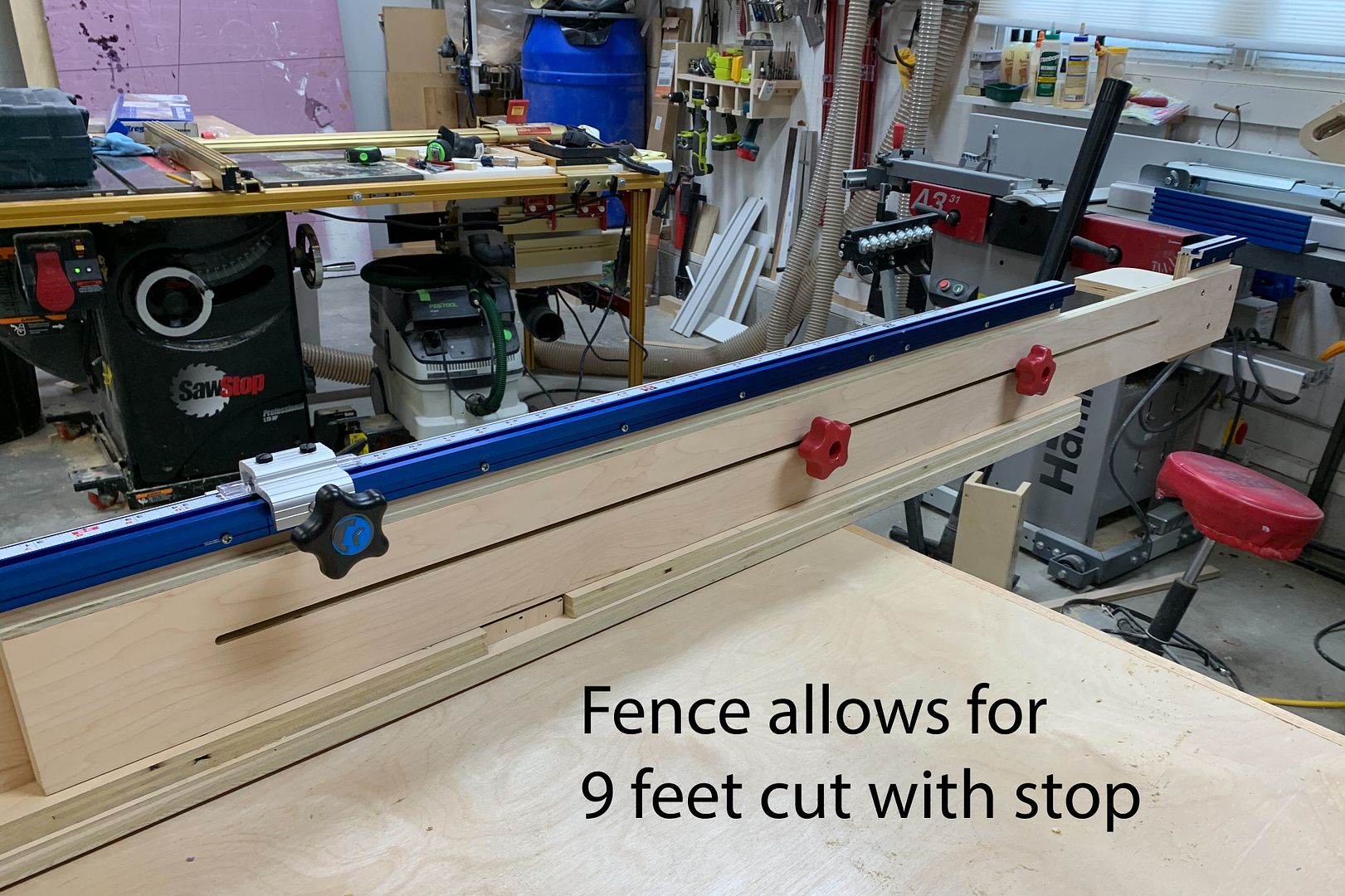

What do you like dimension (L/W/D) wise on this kind of work station. I think for dust collection, which I know is a problem with these saws I will position a shop vac/DD set up below it. I will get a new chop saw for this? I do not want a slider as I don't want this station to be to deep. Shelves and drawers will be below. Fence? Pictures would be great and I am much obliged for any guidance.

Reply With Quote

Reply With Quote