Hello

Im looking for some dust collection advice as I am unable to find the answer online.

I’m in the planning stages of setting up my garage with a few items: table saw, mitersaw, router, small drill press, circ saw and jig saw.

All equipment will be used from the same workbench roughly.

My dust collector is a Magnum Industrial 1.5 HP Dust Collector with Canister

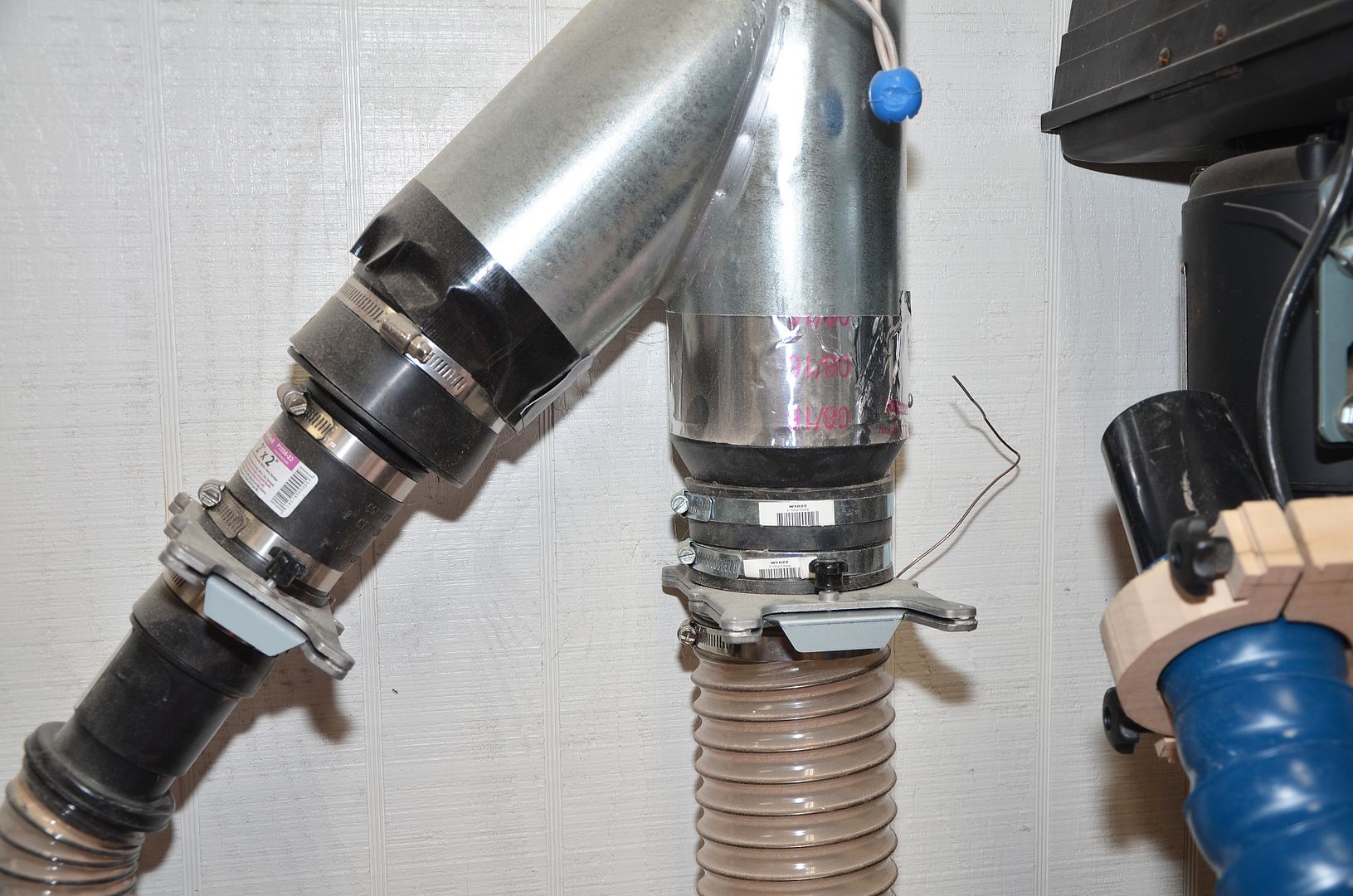

11-250 with 1280cfm. It will be Adapted with a cyclone for two stage. It has the option of single 6” or dual 4” connections.

Ideally I would like to have dust collection on the top and bottom of each machine. For example the router to have 1 on the fence and one below the router cabinet. What would be the best approach:

1. Run both 4” dust collection to the machines, use 4” hose to the bottom and 4” to 2” adaptor to the devices built in dust collection fitting. If option 1, should I have 2 cyclones one for each 4” hose.

2. Run 6” to the bottom (I don’t see any 6” hoods/flanges, I only see 4”) with a 6” to 4” hood/flange and add a separate shopvac to the 2” device?

3. Run 6” to the device and have a 4” T spit to run 4” to the top and 4” to the bottom?

Or any other suggestions would be appreciated.

Reply With Quote

Reply With Quote