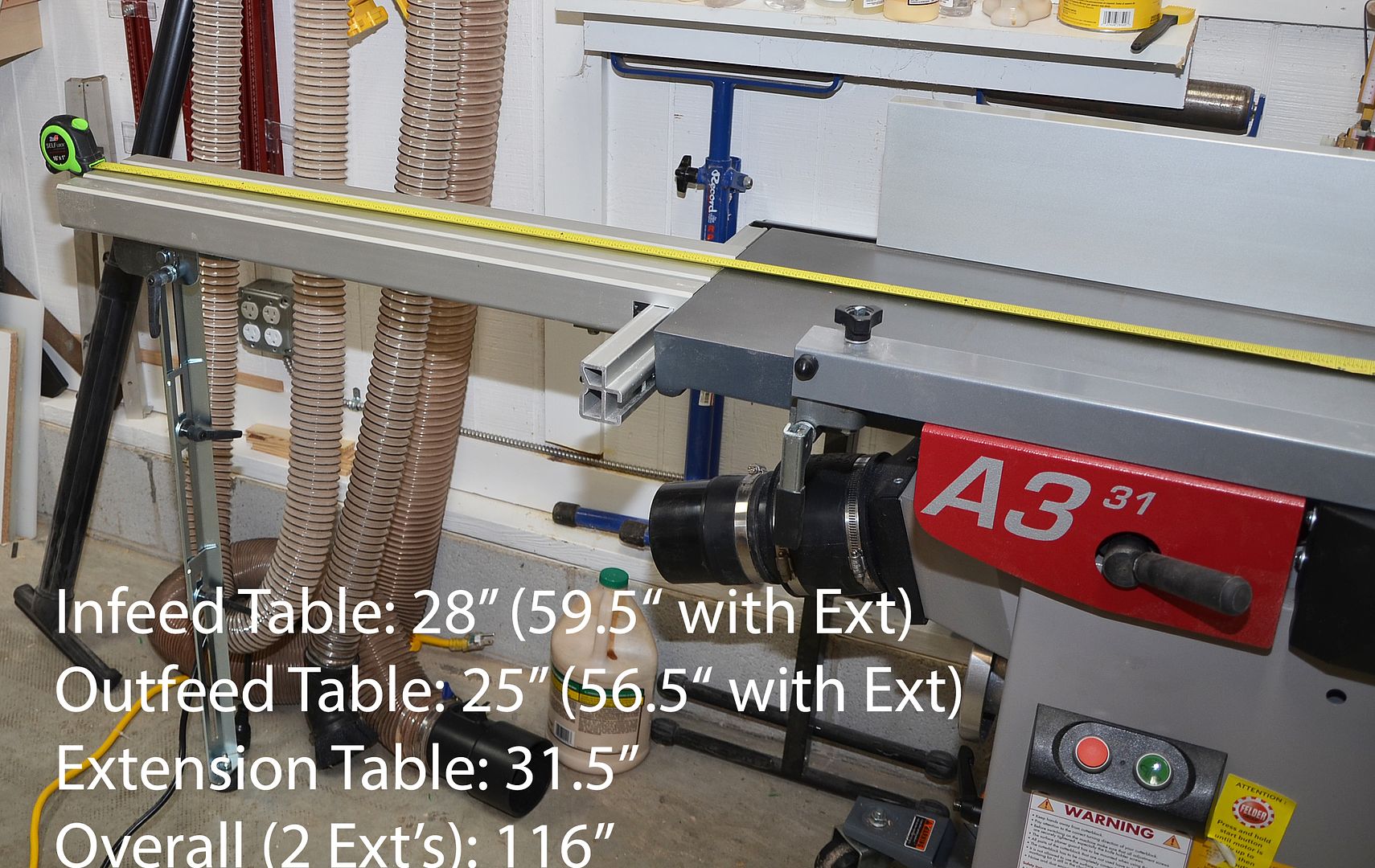

Hi Martin, I have a Hammer A3-31.

The longest boards I typically joint are about 6 feet long. I do have extension tables however I don't normally use them except on the planer outfeed (at 6 metres/minute feed small pieces were falling on the floor before I caught them).

The longest piece I've jointed has been a bed rail, I did use the extensions, short one on the infeed, long one on the outfeed.................Regards, Rod.

Reply With Quote

Reply With Quote

Now I skip plane rought boards to get an idea of the grain then cut to rough length before flattening and planing. Much less waste and easier to handle. One rule of thumb I've heard is you can face joint a board 1.5X - 2X the length of the jointer beds.

Now I skip plane rought boards to get an idea of the grain then cut to rough length before flattening and planing. Much less waste and easier to handle. One rule of thumb I've heard is you can face joint a board 1.5X - 2X the length of the jointer beds.