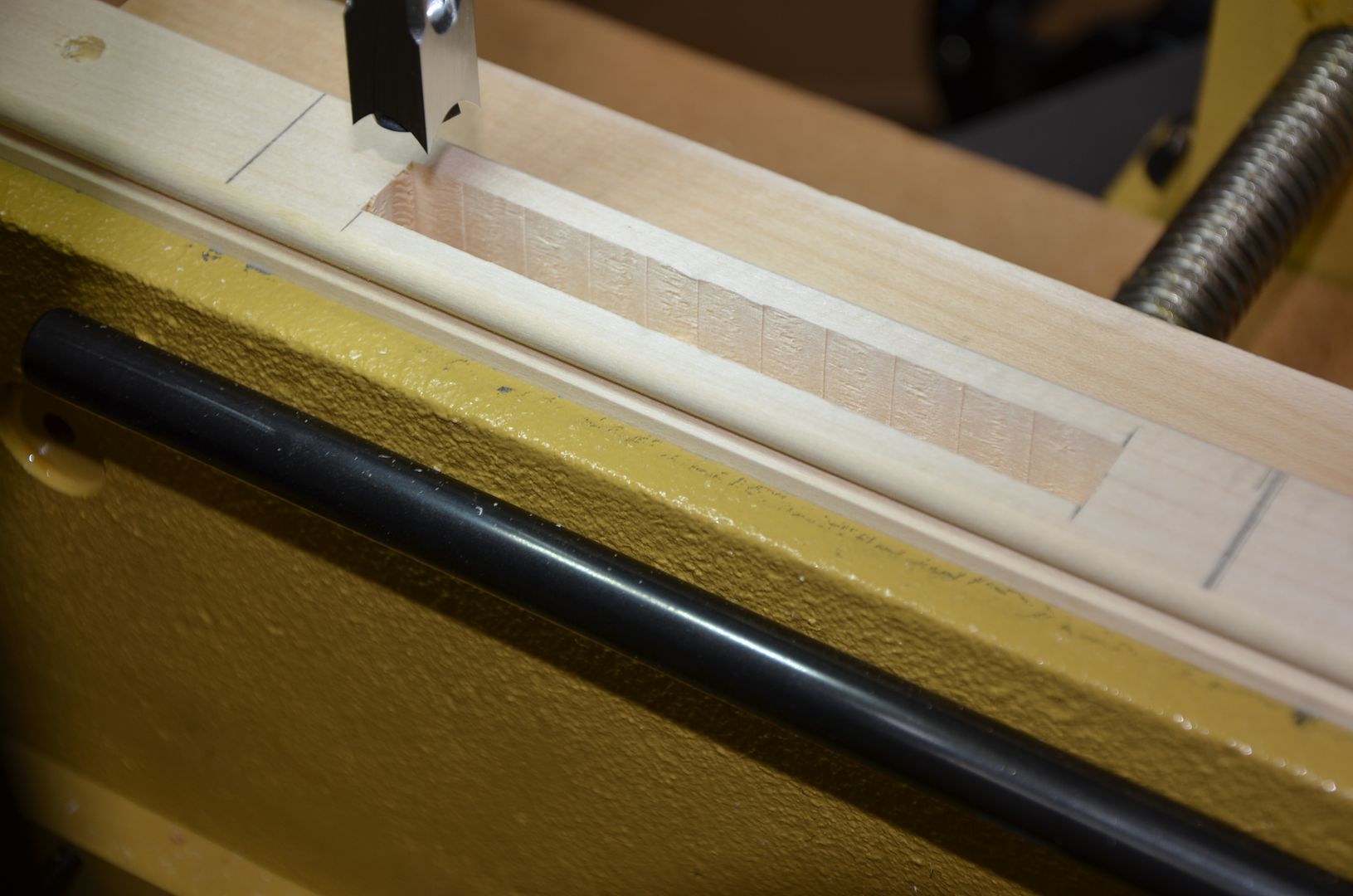

My experience with mortise & tenon joinery is very limited, so I really don't understand the round cornered mortise mating to a square cornered tenon as alluded to above. If the sides and ends of each are properly sized for a glue-up then how does a square corner fit into a round corner? I just see an interference fit that prevents assembly of the mating parts. I can accept a rounded tenon fitting into a square cornered mortise, but not the other way around. Perhaps my age is preventing me from understanding, but what did I miss from the above posts?

Also, I believe a round corner is less apt to fracture/split that a stressed square corner, so I've used the rounded corner for both the mortise and tenon.

Thoughts entering one's mind need not exit one's mouth!

As I age my memory fades .... and that's a load off my mind!

"We Live In The Land Of The Free, Only Because Of The Brave"

ďThe problems we face today are there because the people who work for a living are outnumbered by those who vote for a living."

"Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill

Reply With Quote

Reply With Quote