This is part 2/completion of build thread for a poplar Craftsman// Greene & Greene style coffee table 22” wide x 41” long x 21” tall. Open shelving on both sides with the central nest of 3 drawers. Part 1 for initial construction that is separate posts.

Rationale for this build is twofold: using up accumulated shop lumber too small for larger projects and also an attempt at redemption. I built a similar, slightly larger version of this table out of QSWO with an attempted a “Stickley” finish. Turned out bad! The finishing regimen was way over my head with multiple stains followed by surface topcoats etc. Resulted in a terrible, muddy finish-obscuring the compass inlay on the tabletop, in addition to my many other mistakes. My plan is to die the Poplar black, to hopefully hide the green color in the Poplar, while still allowing the figure to show through. Sounds like a very iffy strategy, but I guess we’ll just have to see!

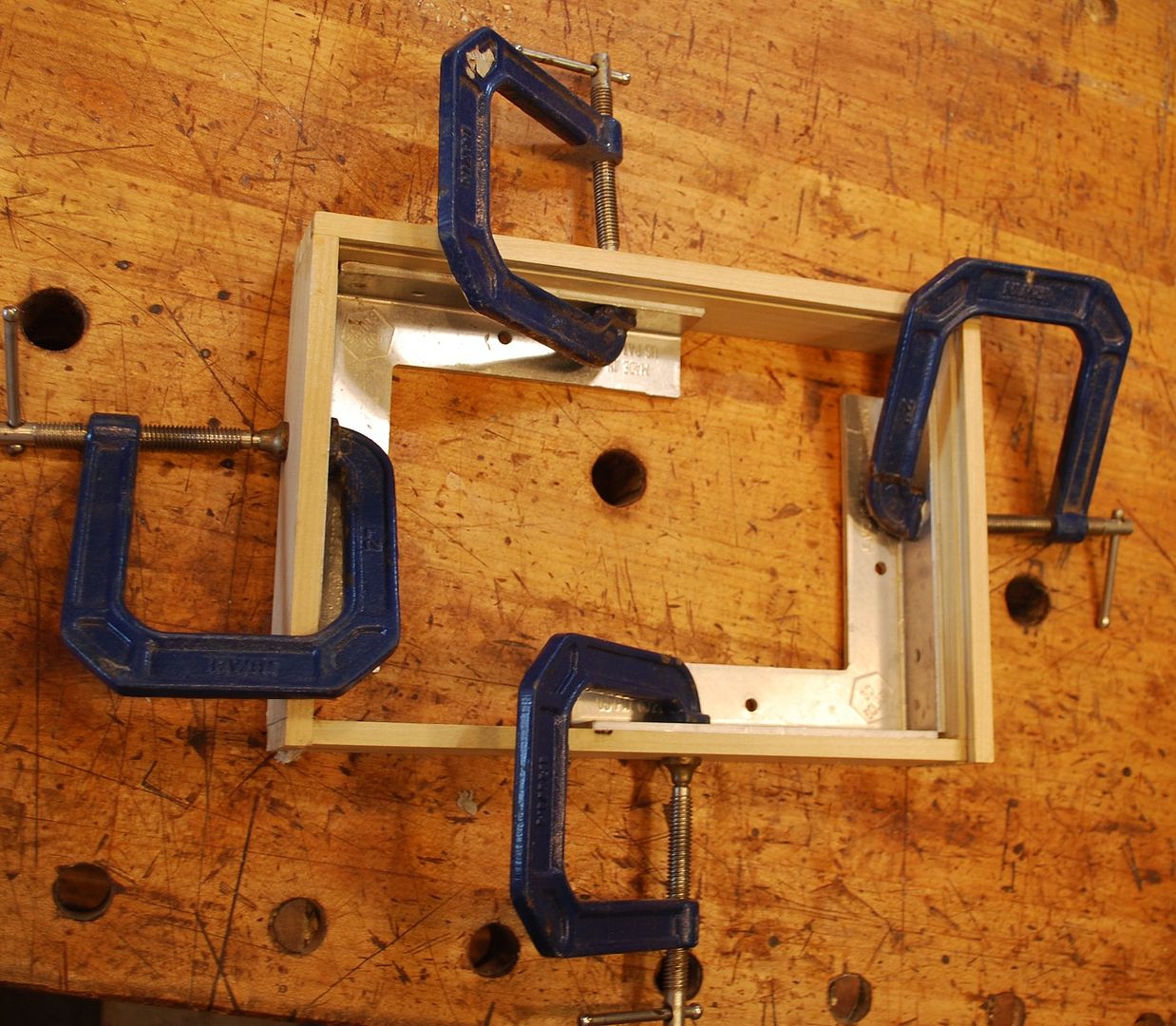

Here’s some pictures of building the 6 drawers that fit in the central portion of the coffee table. Nothing particularly insightful other than dividers and 90° clamping squares are helpful.

Creating the breadboard ends for the tabletop using shop built rabbit plane (probably one of my most useful shop built tools), and small shoulder plane for trimming shoulders of the breadboard rabbit right to the layout line established with marking gauge.

Here’s the layout for tennons and corresponding mortises for breadboard ends. No pics, but I find simple story stick super helpful for transferring width of tennons from one side of the tabletop to the other.

Reply With Quote

Reply With Quote