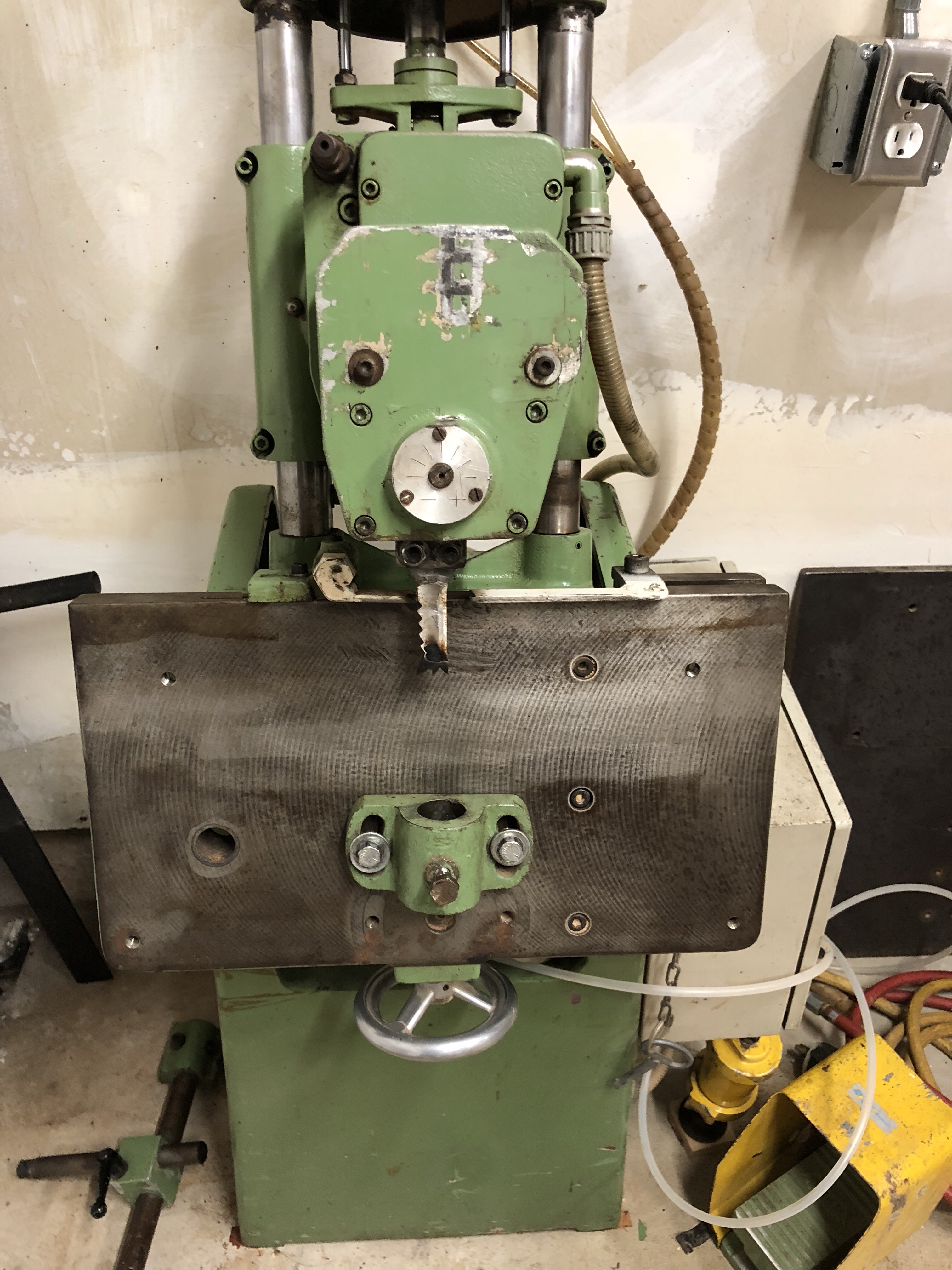

After a long but mainly passive search, one of these machines came up for sale near me. I plan to restore it. It runs well and the pneumatics function but it has a few points i need to address.

If nothing else I can greatly admire whomever designed this machine, it leaves me in awe a bit.

Reply With Quote

Reply With Quote

Thanks for sharing that video, Mark!

Thanks for sharing that video, Mark!