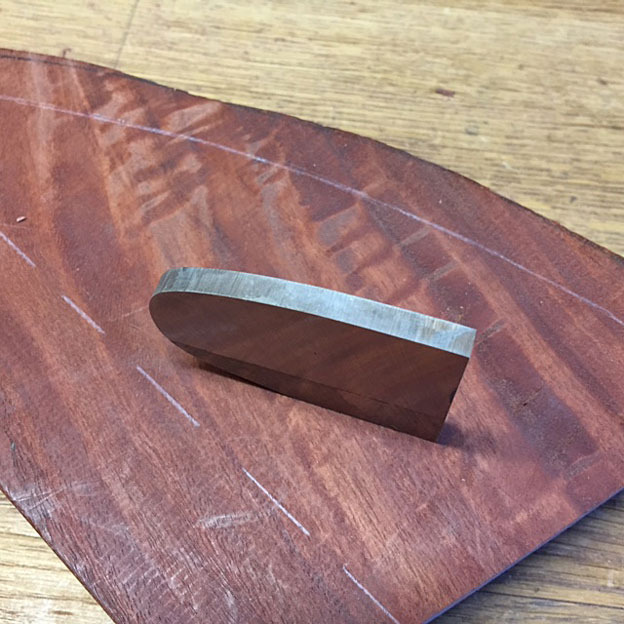

My now deceased father showed me 3 or 4 decades ago how to grind a used up mill file in much the same way as Derek's, the Stew Mac (which I have) and Jessica's suggestion for removing the bevel of a chisel. A scraper that does not get much love, but is extremely effective, is a Stanley 82 or even the 83. Another is what Lee Valley refers to as their chair scraper. These latter mentioned scrapers are quite capable of fine work, if you take your time with edge prep.

If the thunder don't get you, the lightning will.

Reply With Quote

Reply With Quote