Hey all,

I am getting ready to break ground in my basement to convert it to a workshop. I'll have a dedicated 15'x18' space to make things happen. It's not ideally how big (or small I guess) I would like it to be, but I've drawn out plans to make sure I'll have enough room for my essentials. I'll just have to get crafty when it comes to storage and things like that.

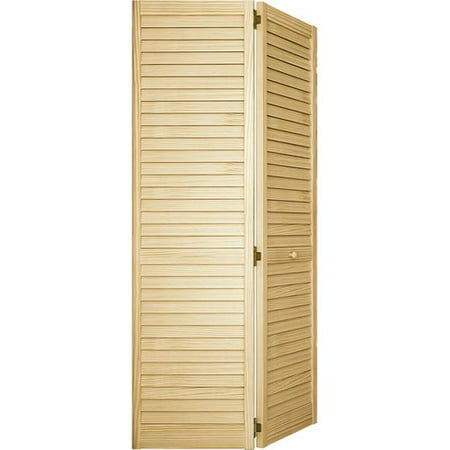

Q1. My home HVAC is in a closet that is built under my stairs to go upstairs which will be part of my workshop. I don't want any saw dust causing issues with it. I was thinking of hanging a thick blanket (maybe a sports theme one to look decent?) in front of the door to sort of "filter" the air going into there. Right now my closet doors are louver style, so there are plenty of places for dust to find its way into the closet. Would love some recommendations.

Q2. I have most of the portable power tools, and hand tools to get me started (drills, impact drivers, block planes, stanley 3 thru 8 bench planes, saws, etc etc), but I am pretty limited on the larger tools. I have a Hitachi C10RJ job site saw that works for my needs now (have to do all my big cuts outside), but definitely not something I want as a dedicated table saw. Here is my "wish list" that I tried to keep under $5k (incl. shipping). These prices are all new, so I will definitely look at the secondhand market to save some money. Do you think a 15'x18' workshop would be able to house these comfortably? I mean they look fine in my drawing plans, but that doesn't always work out in reality!

1) Sawstop 36" Contractor Table Saw w/T glide fence $1950

2) Rikon 1.5HP 14" band saw $800

3) Dewalt DW735X Planer w/Shelix cutter head $1100

4) Festool ROS $200

5) Strong shop vac + Dust Deputy for dust collection ~$200

6) Disc/Belt sander combo $75 (Harbor Freight)

7) Spindle Sander $130

Reply With Quote

Reply With Quote