This is a long post, and so feel free to skim through it. Who needs another dovetailing documentary?

This one is specific to the back of a drawer, and so is different from the through dovetails which one might use on boxes. Also, I have a few techniques to share, ones that I do not see mentioned much, if at all.

The drawer is one in the Apothecary chest. What has been shown before was the dovetailing hijinks needed for the curved fronts. This affects the drawer sides as well, since they are not equal in length. In fact, the length for the sides need to be measured individually.

Here is a drawer front with sides ...

It is fitted in the recess and positioned carefully (top right hand drawer) ...

At the rear of the chest, the drawer sides are clamped to avoid any movement ...

Now the drawer side length can be marked. The final length is 10mm in from the back of the recess.

We are ready to begin joining the rear of the drawer. A drawer back has been added to the parts ...

"Drop" (the gauge) for the width of the drawer back and transfer it to the ends of the drawer sides ...

Now do the same for the drawer sides and transfer this to the drawer back ...

With 24 drawers, it was quicker and easier to make up a template for positioning the tails ...

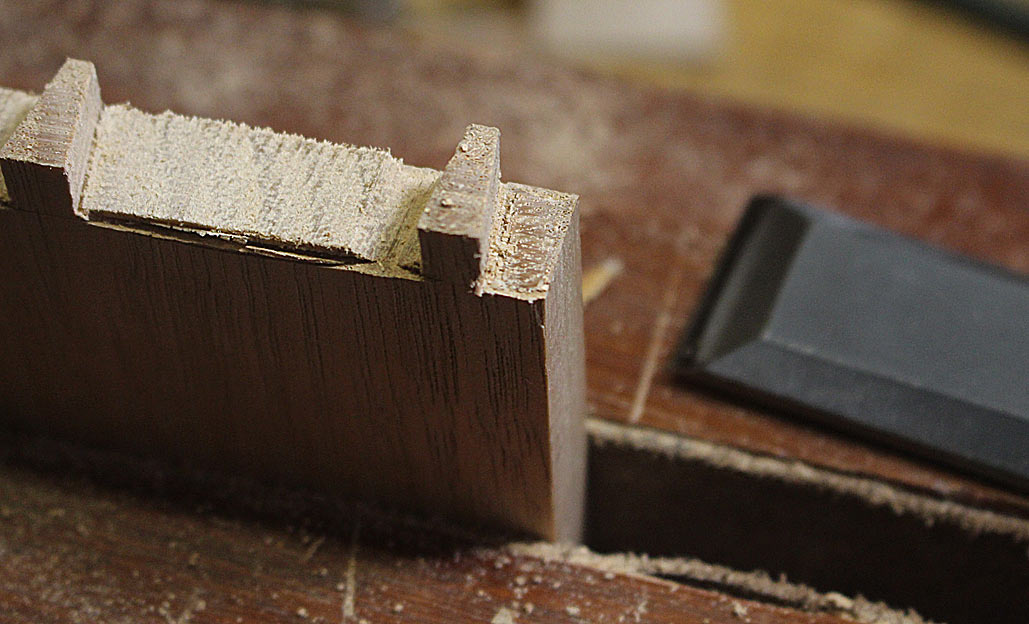

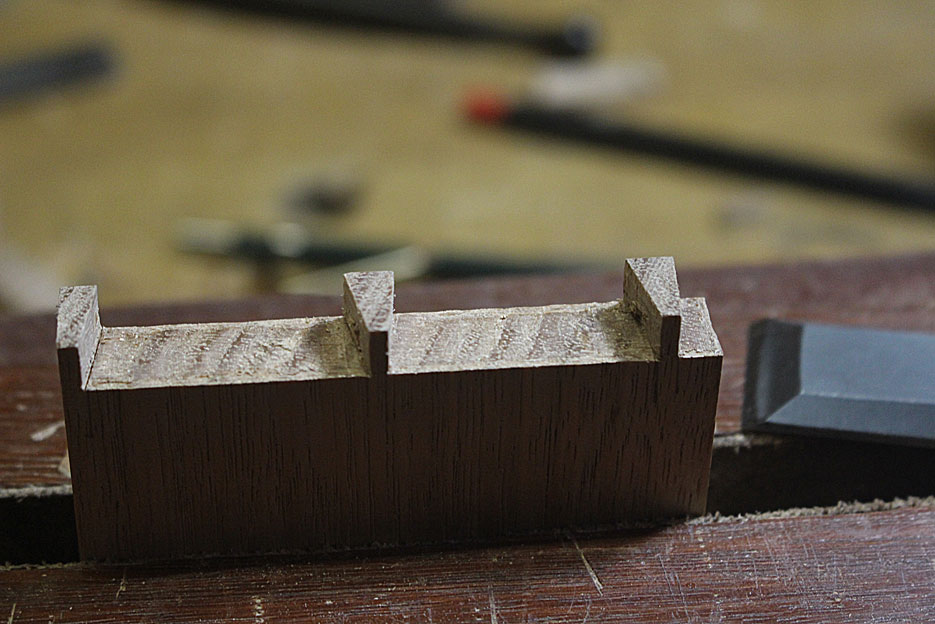

Note that the tail alongside the groove (for the drawer bottom) is not a triangle, but one side is vertical (flanking the groove) ...

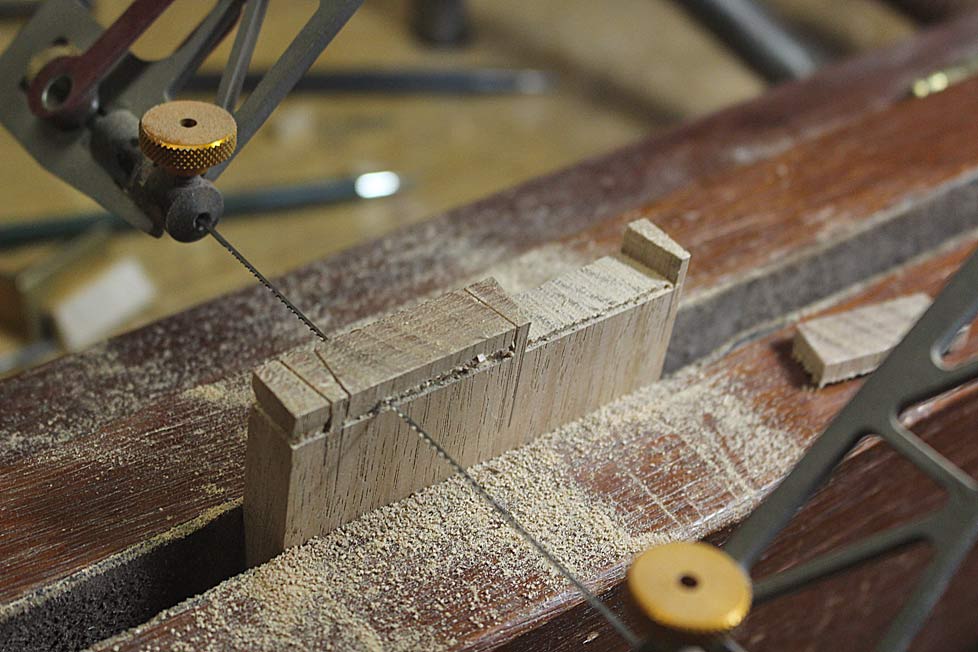

Saw both drawer sides ...

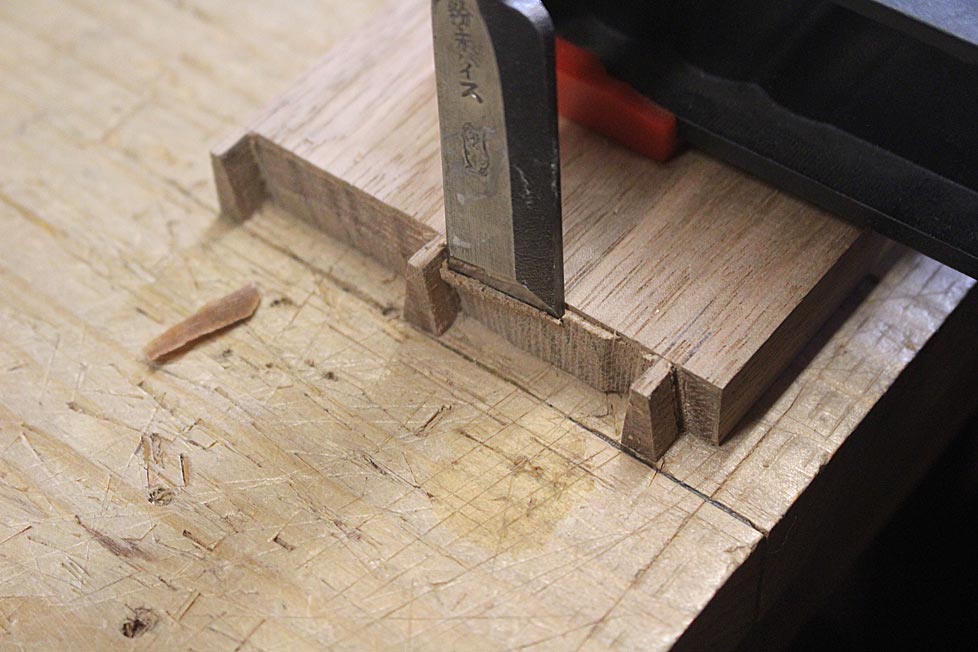

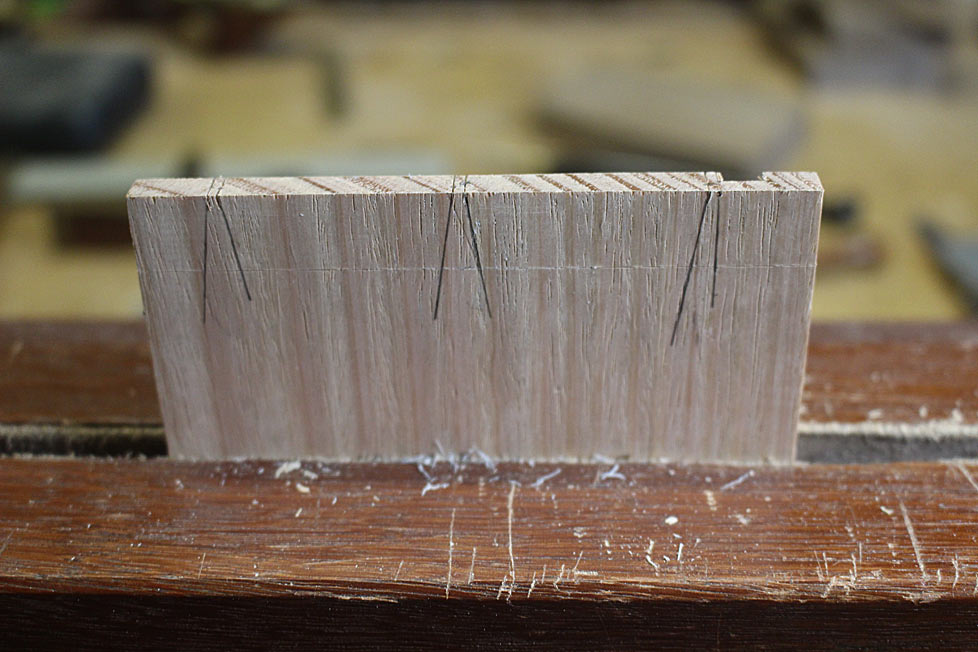

Time to remove the waste from the tails. First, create a chisel wall for all the tails ...

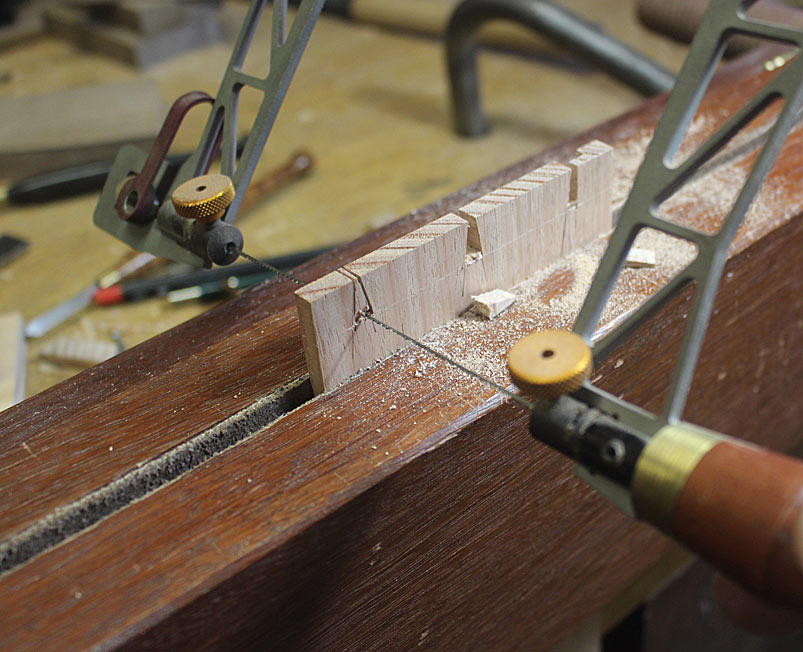

Fretsaw the waste to 1-2mm from the line ...

Remove the waste in thin layers for the cleanest finish. Note that the Tasmanian Oak is too thin (6.5m) to confidently pare half way by hand (better to use a hammer for precision). By taking very fine layers it is possible to push through the board without spelching the other side ...

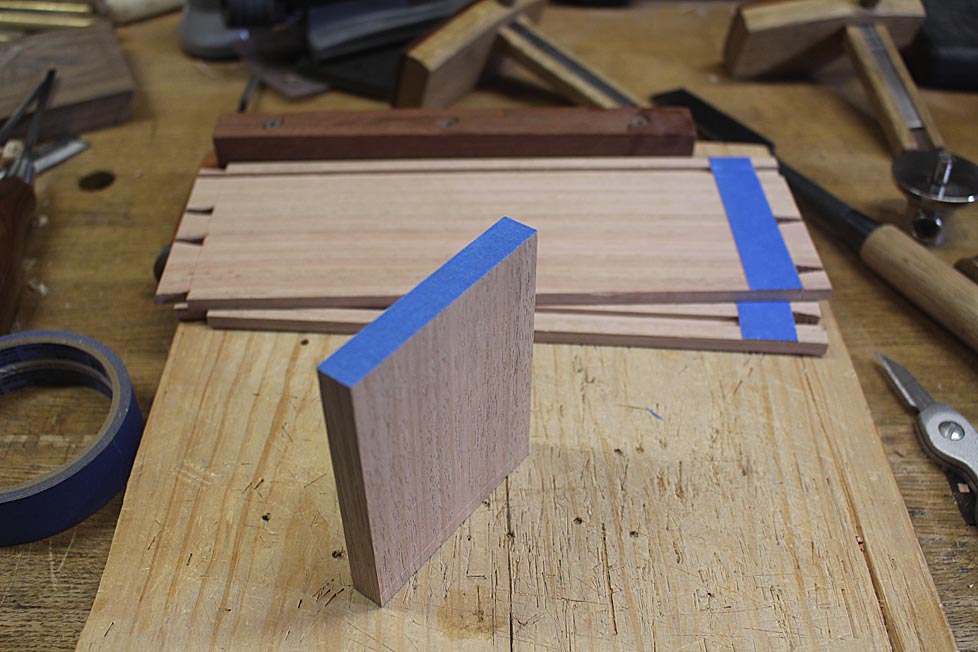

Blue tape on everything!! The drawer sides have blue tape ala the #140 trick (I wrote this up recently on my website). There are 4 layers. The drawer back has tape to aid in transferring marks (don't knock it if your eyesight is better than mine).

Transfer the tails to the pin board ...

The great thing about the blue tape method is that you only need one knife stroke to cut through. No sawing away to make an impression in the end grain. Saw against the tape. Go for it!

Reply With Quote

Reply With Quote