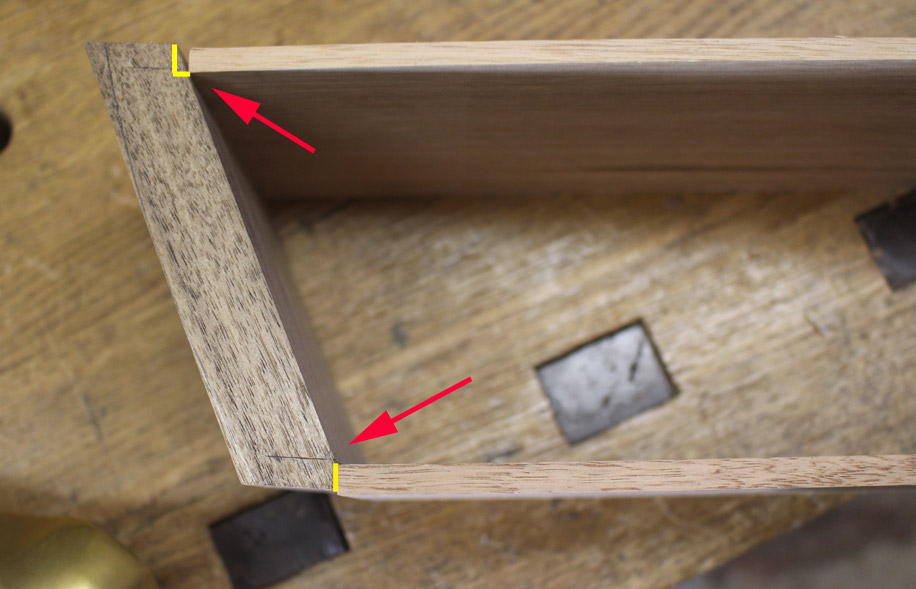

I always like to try things. When I read Derek's thread about angled drawers and his approach I just had to try it by hand. I had a piece of walnut scrap and an oak scrap. I marked it out at 15* penciled it in hand cut the angle on the ends penciled in some dovetails and sawed it out. Chopped and pared out the waste. This is what it ended up. Not bad but not easy at all. Took an hour just for one corner. Without setting up some fixtures to aide in the work I would not want to do 48 drawers. Kudos to Derek and his methods. I just enjoy experiments.

Jim

Reply With Quote

Reply With Quote