Today was a public holiday in Western Australia (WA Day), and so I managed a few hours in the workshop this afternoon ("arvo", which is afternoon in Australian). The morning was filled with writing bloody reports. Aren't I the lucky one! It was great to escape back to the build.

I wanted to show some of the other preliminary tasks that are needed before one can begin dovetailing the drawers.

Here are the collective drawer fronts. They have been sized for height ...

The original rough sawn board of black walnut was cut into three sections, and each section is enough for two rows. The rows were separated, and will be used sequentially. This is shown above.

The original test drawer front served as a template for width ..

The plan is to work with one vertical row at a time, since each will have the same width. This will reduce set up time fitting each drawer blank.

Here is the template drawer front fitted to the lower most drawer ...

All the drawers in this row have the same width.

Fitting the drawer front involves (1) sizing the height ... this was done (above), then (2) mitering the sides to fit the drawer opening.

Begin by obtaining the angle across the opening ...

That was for the first row.

This is for the second row.

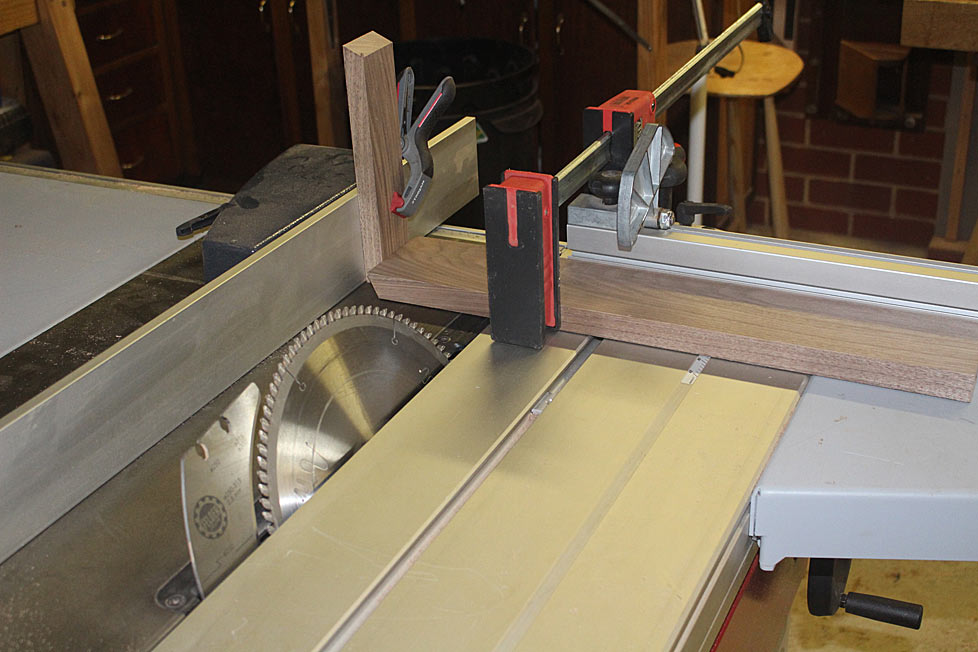

Transfer the angle to a second sliding bevel (to set the blade angle on my table saw) ...

Cut the angle on one end, and then set up the table saw for a repeat saw cut ...

The first row is done ...

A close up of some figure ...

I was looking at the effect of the straight drawers fronts against the curved drawer blades. It was interesting ... no, I'm sticking to curved drawers.

More next week.

Regards from Perth

Derek

Reply With Quote

Reply With Quote