This weekend I spent time preparing to build the drawers for the apothecary chest. There are 24 drawers, which makes 48 drawer sides, plus 24 drawer fronts and 24 drawer backs. And then there are 24 drawer bottoms. And slips for the drawers.

All this before building the drawers can begin. I wonder how long this would take if I did it all with hand tools?

I've been reading the posts by Chris Schwarz about the forthcoming publication of John Brown's “Welsh Stick Chairs”. This was a seminal book in the same manner as James Krenov's "A Cabinetmaker's Notebook". I've not read John Brown's book, and I am looking forward to doing so. I have read Jim Krenov many times. It seems to me that they are similar in the way that they value the craft that is woodworking, and the importance of hand tools. However, they differ in the way they view machines. Krenov used his to prepare the way for hand tools. Brown would have nothing to do with them. It seemed he feared that craft would be lost if machines were used ...

"The hand too maker needs the best bench he can make – or afford! You must know your tools, what they are made of, fine adjustments and sharpening angles. Everything must be clean and sharp. Tools talk to the craftsman, and will let you know when they are right. What the machine does by noisy, brute force, you will be able to do with quiet cunning"

"I would not go so far as to say that there are no skills necessary to working machines. It is important to be able to read and interpret complicated instructions. What you end up with is engineering skills – precision engineering in wood".

Link: http://tonykonovaloff.com/?page_id=54

What has this to do with the work I did this weekend? Well, I could relate to the role of engineer. Preparing the wood for the drawers with my machines was the work of a machinist. Would I have rather spent the time doing this by hand? Well, I have done this in the past - I worked almost exclusively with handtools and a few hand power tools for over 25 years before purchasing a tablesaw, jointer, thicknesser/planer, and bandsaw. I began upgrading these over the past 7 years. I would not go back. Machines do not replace handwork.

The question is whether this compromises the work I do?

The drawers have Tasmanian Oak sides and back. The drawer front will be Black Walnut to match the carcase. The oak has become harder to come by in Perth. I prize it because it is all quarter sawn, which is ideal for drawer sides as it is stable. It is light in colour and a good contrast to dark timbers. But I have so little now. Much of it is narrow boards - I grabbed everything that my local Bunnings store had a few years ago when I heard they were no longer going to sell it.

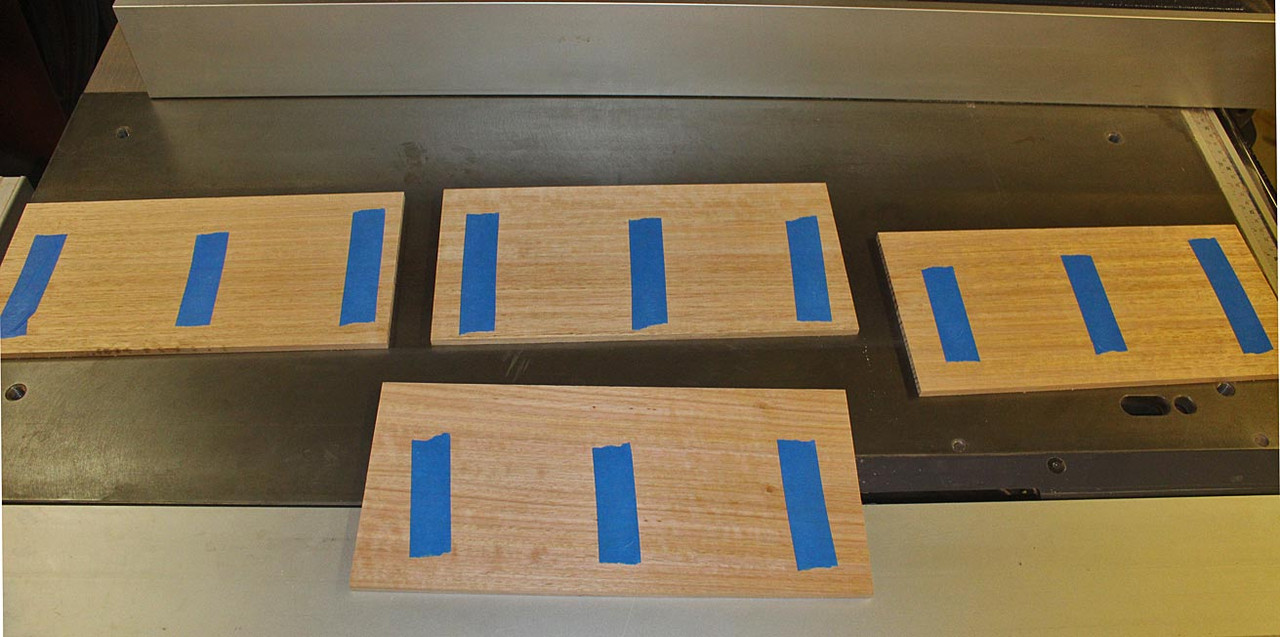

These boards would be resawn and book-matched to become the drawer sides ...

Where my jointer-thicknesser/planer excels is that I can cut the boards to short lengths, and still process them. Shorter boards will not lose much waste when flattening ...

This was at the end of Saturday. Drawer sides taken to 1/4" and stickered. I have had good fortune with this method in the past. The wood is stable and cleaned up with a cabinet scraper. If there is any slight movement, it will be taken out when dovetailed.

The black walnut is rough sawn. This board is 1" thick and will make all the drawer fronts.

The tablesaw is new. The slider is magic to rip as well as crosscut. Here is a Frans and Fritz jig used to quickly rip the short lengths into two sections (= two rows of drawer fronts) ...

This is just raw material. It does not replace the handwork in building the drawers.

I have begun fitting the drawer sides to the drawer blades ...

There is so much more still to do ... and I have not even made the drawer bottoms or slips.

Regards from Perth

Derek

Reply With Quote

Reply With Quote

Is that a Davis and a Starrett I see there?

Is that a Davis and a Starrett I see there?