Well the carcase was finally glued up, everything square as can be ... and I forgot to take a photo of this!

However, while planing the outside, I discovered that the black walnut required nothing more advanced than a simple single-blade common angle plane. Many years ago I received a smoother from Steve Knight. This was the first occasion I got to use it.

Just wonderful to work this wood!

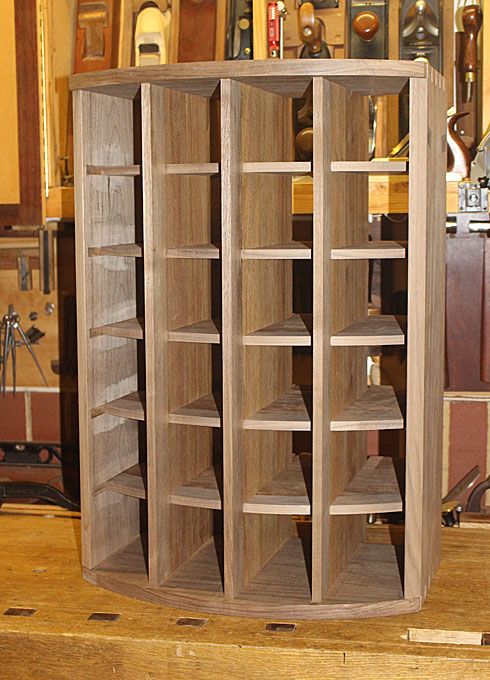

The next step was to complete the vertical dividers. These were inserted and, with some relief, these were square as well. A reward for attention to detail?

The photo below shows the next steps: the stopped dados need to be extended, and the faces of the dividers need to be shaped to match the angles of the carcase.

The dados are marked to 12mm from the edge ...

... and chiselled and pared away ...

These were then glued in place (yes, I got that one!) ...

During the dry fit I had been careful to fit them flush with the rear rebates, and then saw them parallel. This made it easier to ensure that they were glued square (since the fronts could be flush with the lower edge of the carcase, but not the upper edge, which has an overhang) ...

Time now to install the drawer blades. These were positioned loose, as before ...

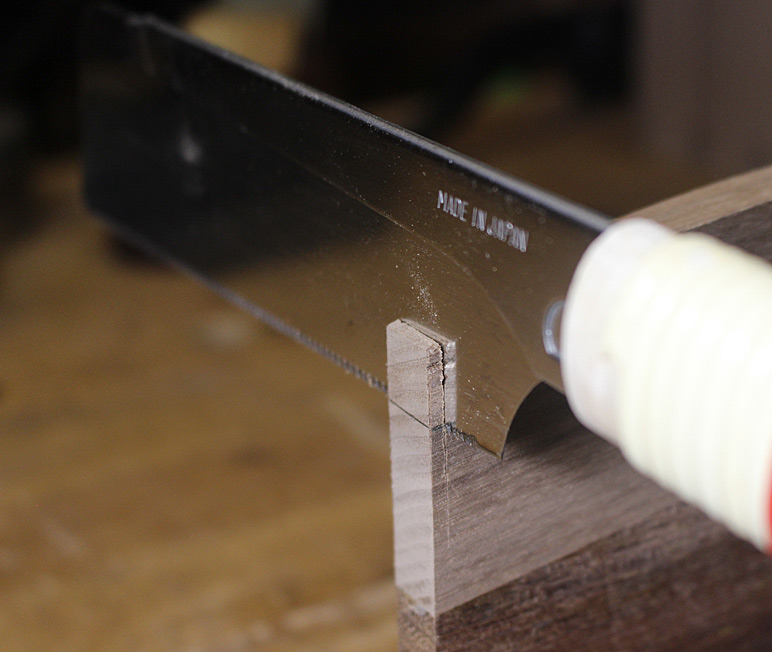

To fit them to the stopped dados, the front was marked out ...

Below the rebates are marked and knife walls cut ..

The first saw cut is across the top to establish the face ...

Then saw diagonally along the vertical line ...

.. before finishing on the horizontal ...

This will maximise obtaining a straight saw cut.

Reply With Quote

Reply With Quote