Some time back I asked a woodworker friend - who specialises in dust control - about drilling a ZCI to increase airflow to the main dust collector (I have a Hammer K3 with a ZCI from Felder). He said "

don't do it". Apparently, after much research, any holes drilled actually restrict air flow. I thought this illogical, but he showed me the studies, and it required very careful placement of holes, and of a certain size to make any positive difference. Simply drilling holes at random makes the airflow worse!

Well this information came back to me today after I tested out my over-the-blade collector. I am still shaking my head at the results.

My dust collection is a 2 hp Carbatec with 5" hose. I would prefer 6", however all my machines are by Hammer - the tablesaw is a K3 - and they have 5" outlets. I plan to add 6" ports when I upgrade the DC. The suction from the DC is adequate for all the machines I have. It is not as though there is inadequate suction. It is not enough, however, to suck up via both the main outlet of the tablesaw and the blade guard .. (or so I thought - now I am having second thoughts ... the plot thickens

). The outlet from the blade guard is (from memory) 2".

So a few months ago I added a hose via my Festool CT26E to the blade guard ....

It seemed to work, but I must admit it was more work and I got lazy, and so did not use it much.

Today I was fitting some dividers to an apothecary chest I am building (see

here for the build), and decided to use the overhead dust collector. I was curious (with this thread in mind) to see how well it collected the dust ...

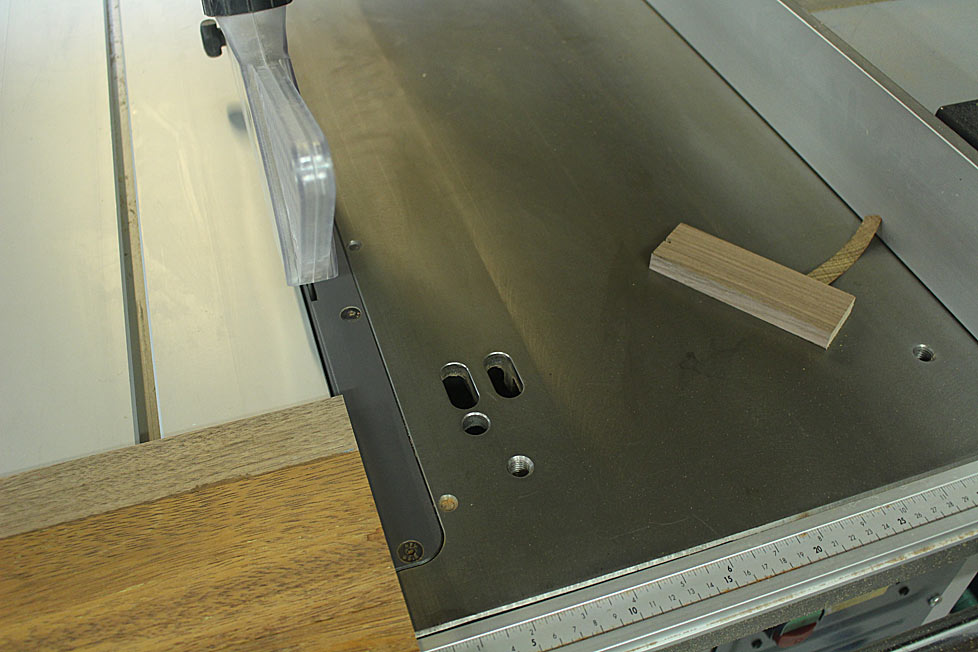

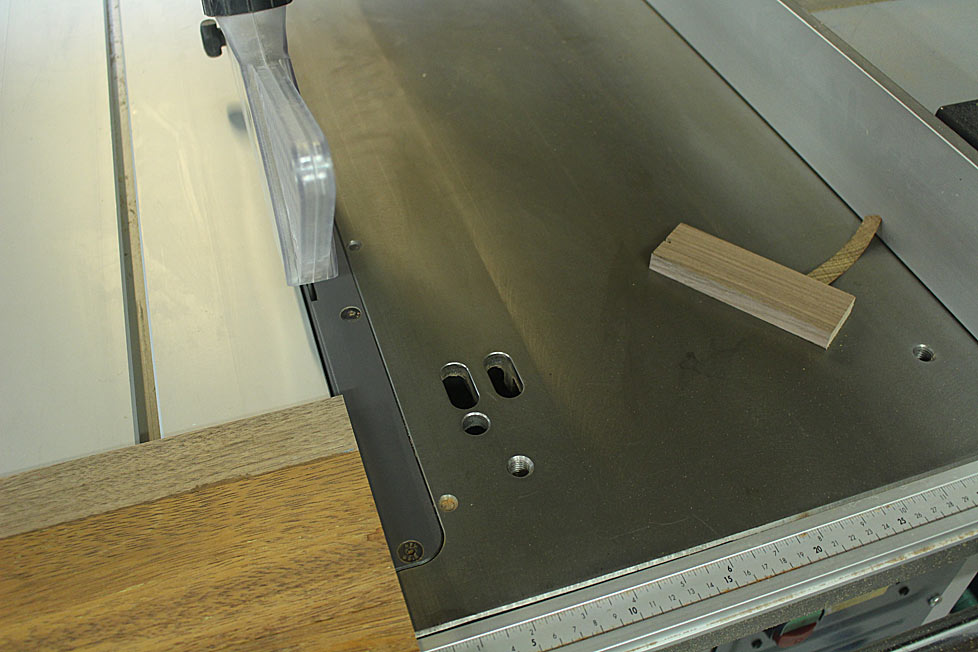

On went the CT26E, and this is the result ...

Dust!

I then had a lightbulb moment and decided to switch off the CT26E, and tried with a second divider ...

No

No dust!

hmmmm ... so I decided to use the CT26E again, and cut half way through the third (and last) divider ...

No dust,

again!

I then tried the dust collector on the remaining half ...

Dust!!

I think even blind Freddy can see the pattern that has emerged.

One last trial. This time I disconnected the hose to the blade guard and capped it. Tried again ...

And that is the way it will remain now.

Summary: overhead dust collection is overrated.

Regards from Perth

Derek

Reply With Quote

Reply With Quote

). The outlet from the blade guard is (from memory) 2".

). The outlet from the blade guard is (from memory) 2".