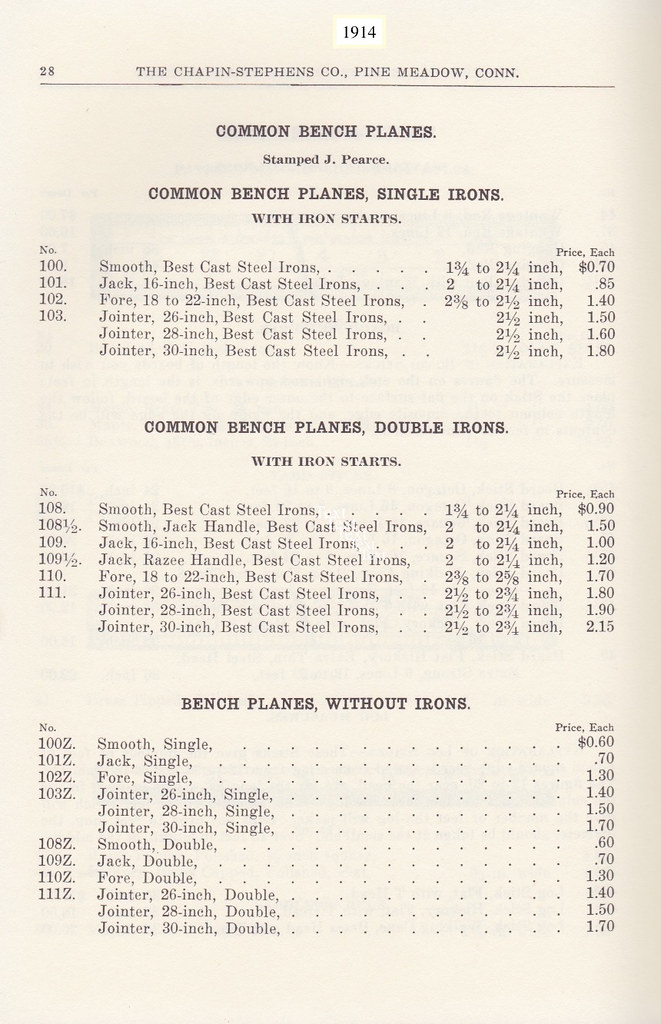

Received this 16 inch wooden Jack Plane on Saturday morning from an Australian seller. It was manufactured by The Chapin Stephens Co; New York (USA). Both the main stock of the plane and its wedge are both stamped by its previous owner J.LOADER. A special thanks to SMC members Joe Bailey & Don McConnell for providing the information that enabled this planes manufacture date to be narrowed down to 1901-1929. Note: Stanley Co. bought the firm out in 1929, and discontinued the wooden plane making side of this business.

You will note from the following photo that after unpacking, the wedge is sitting unusually high within its abutments. Details as to why will become more evident further into the post.

1st up is the condition of the original iron. Its lost around 1 5/16" of its original depth. Likely its been left within 1/2" of usable blade below the softer laminate. The decision was made to put the original iron aside, and replace it with a Nos Isaac Greaves tapered iron of matching width. I will reuse the original cap iron.

Moving onto the bed on the main stock. Chalking indicated the bed had moved was out of flat.

The bed was re-worked until the chalking indicated the full surface of the bed was back to being flat. The middle area of the bed was then lightly worked back to leave the critical areas slightly proud.

Moving on to the fit of the wedge within its abutments.

The wedge was then lightly flat sanded on both of its primary faces. The abutments were also lightly worked back to increase the clearance at the sole from 1/8" to 1/4". That will allow me to later proceed with a partial infill to close up the existing mouth opening. (A full laminate wont be required.) Fine tuning the fit of the wedge was then carried out with the aid of chalking, until contact was made across the full length of the abutments on both sides . 2 additional points to mention. The back of the wedge that allows the upper domed nut of the cap iron to pass unhindered had to be further excavated by 1", to allow the cutting iron to meet flush with the sole. (cap iron was set 1mm behind the irons cutting edge). The ends of the wedge tines also needed trimming back to insure they didn't encroach into the later fit of the 1/4" thick partial laminate. The following photo's show the fit of the wedge after the abutments were fettling in.

The top of the wedge was shortened by 1/4" to remove the damaged area caused by previous hammering.

The original finish on the wedge was then cleaned down using denatured alcohol, before an antique mix comprising of red and black powder tint, mixed into a small amount of Danish Oil was then applied. The following photo shows the end result after all the above mentioned had been completed.

Next on the list of things that need to be done is to re-flattening the sole, and fit a partial laminate to close up the existing mouth opening.

regards Stewie;

Reply With Quote

Reply With Quote