I know this question comes up a lot, but the search results leave something to be desired. Rather than dig through everything, I am hoping to trouble you guys for a look at your dust collector closets?

I'm contemplating a variety of door solutions which will keep the sound to a minimum and also look nice. While I'm at it, I decided it would be handy to also enclose the area where the trash cans are, so I can hide everything ugly and noisy all at the same time.

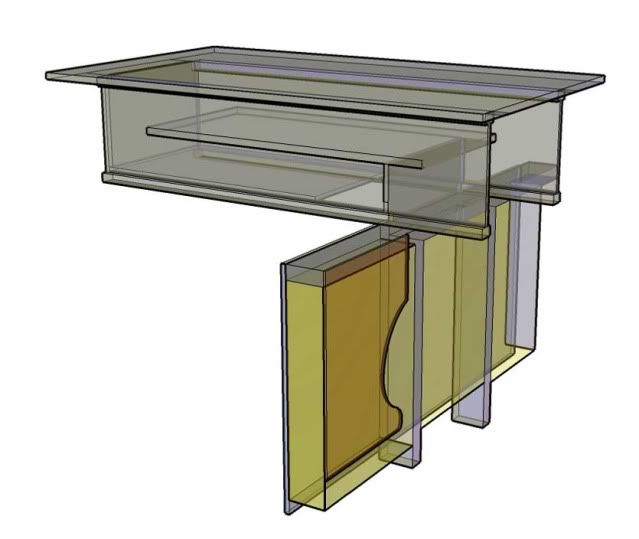

I'm contemplating using sliding doors, but unsure if they will allow enough of a seal to keep the noise at bay.

I'm also considering ways to avoid fixing the wall permanently to the house, and instead making some sort of stand-alone setup that maybe bolts to the walls at two spots but can be removed in the future.

So, I'm sure you guys have come up with some great solutions to this issue, can I trouble you for photos.

Reply With Quote

Reply With Quote

)

)