A client of ours was interested in our making a king sized bed for him, from whose footboard a TV rose.

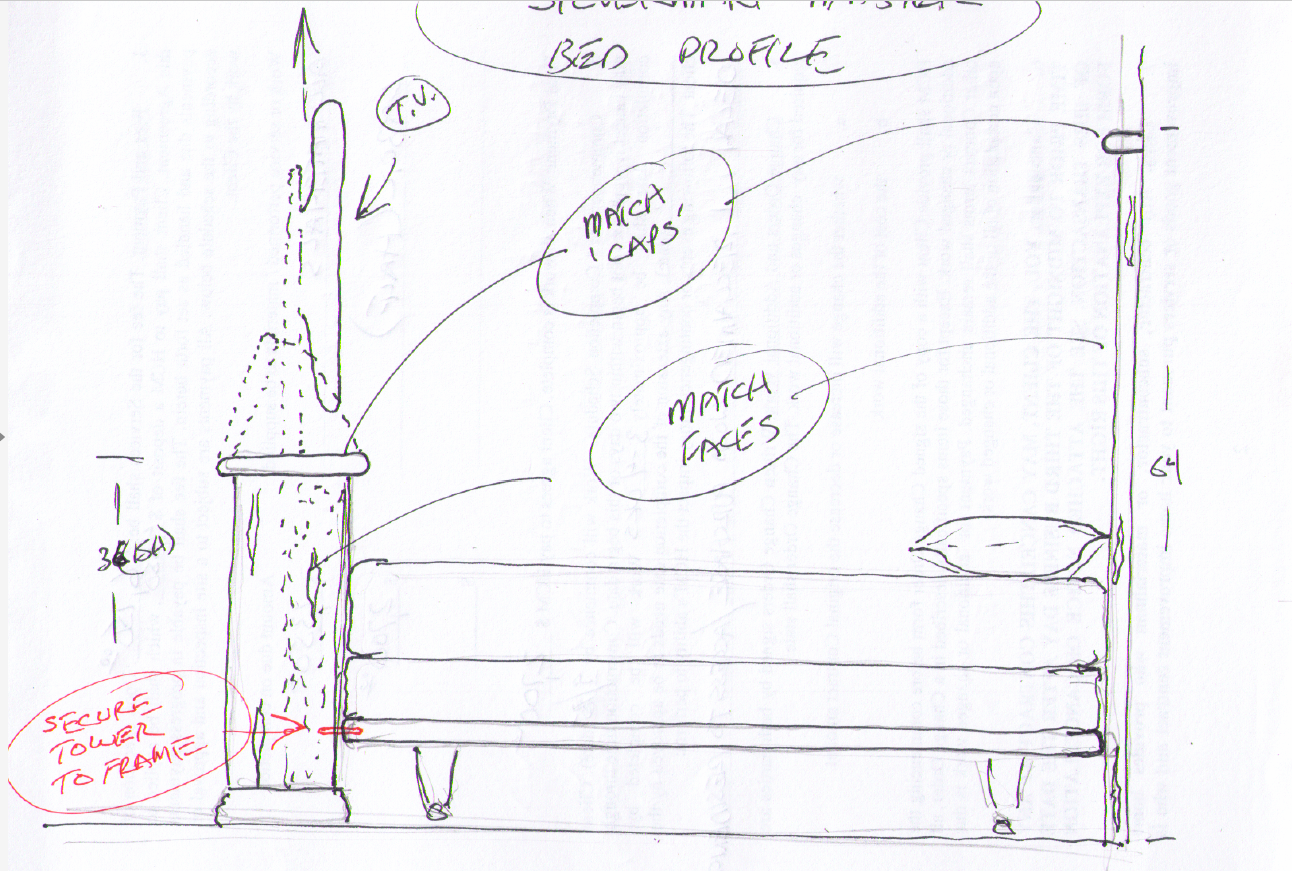

He liked the surface texture and color of aged wood so we took him to a reclaimed lumber facility and found some barn siding in sufficient quantity to make the headboard and ‘cabinet’ footboard. Here is the sketch I did for him as well.

After selecting those boards that would fit well together, we wire brushed them to remove a century’s worth of old dirt & grime embedded in the surface. Then we sanded them just enough to make them smooth to the touch while keeping as much of that aged patina surface as possible.

Here is the headboard (and parts for the footboard) drying after two coats of urethane. The urethane sunk into the surface much like an oil finish does. We wanted some protection but still see and feel the aged texture of the wood.

When building with reclaimed wood, the key is to have no freshly cut edges showing because they’d be be noticeably lighter in color. We capped the outside cut board ends with pieces that acted as legs and that hid those cross cuts at the same time.

Considering both the flat screen TV and it’s lift mechanism, I determined that we’d need an interior depth of ten (aprox) inches. Here’s a video I grabbed while assembling the footboard (console/cabinet). It is upside down on the work bench and all the newly re-sawn surfaces face the cabinet’s inside.

assembling video

We wanted this footboard to occupy as little floor space as possible (it is as wide as the bed but only 12” deep) and the height of the TV & lift mechanism when fully extended made it unstable enough to be dangerous. That’s is why we bolted the cabinet to the bed’s steel frame (shown in the design sketch).

Here’s short vid I took a few weeks after we were done…

(sorry about the cut in the middle / takes too long to go all the way and down, folks)

Finished TV Lift Bed video

Reply With Quote

Reply With Quote