That's a great scan! It seems to confirm what I'd suspected which is if you can get the hang angles lined up there's no particular magic to handle down. Handle up is probably marginally better for the blade straightness but I seriously doubt it all that much better given my sawing technique. I wouldn't have thought about the slots running with the grain but that's a good idea.

I do have two things going for me:

- Almost all the saws I've inherited need new handles so I'm somewhat at liberty to pick the "hang angle" if I may use that term.

- This is Colorado and there is no moisture. In fact the climate is actively trying to dehydrate me and my family into a prune which took some getting used to when I moved here.

The Oracle of Google seems to indicate kerosene will indeed absorb moisture. Pure SWAG, but in this day and age I'm pretty sure a bunch of silica beads or your local disposable diaper hydro gel filling will likely absorb several orders of magnitude more water. And be way easier to contain. Also smell nicer. Also not spill all over. Also not catch on fire.

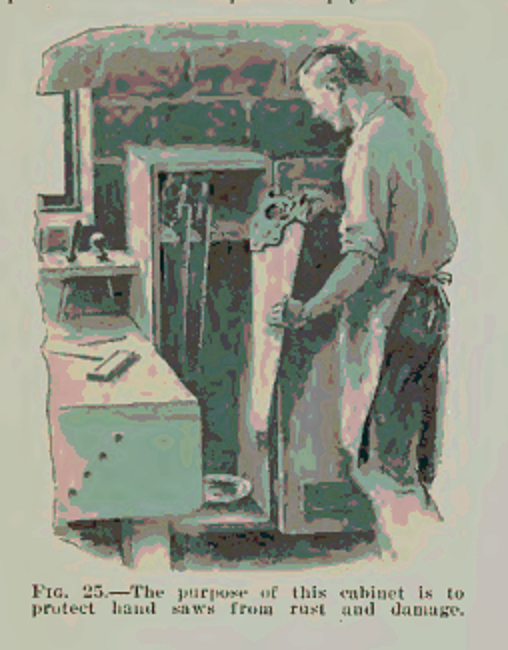

Obviously the trick only works if it's an enclosed cabinet. In my case I suspect most of my rust issues are from sawdust and the salt/sweat from my hands not getting properly wiped off.

Reply With Quote

Reply With Quote

So, one barrel of oil with some holes in it to put saw plates through them, hehe.

So, one barrel of oil with some holes in it to put saw plates through them, hehe.