WOW!!!!!!!!!!!!!!!!!!!!! Nice shop.

Ever find something in the storage building that you forgot you had?I "discovered" my old Pioneer surround sound system over the weekend. I replaced it with a super nice Klipsch system a few years ago. Didn't take long for me to have the old Pioneer in the shop and hooked up. Only problem was the old system has no Bluetooth or even a 3.5 input. Solved that problem today with a trip to Best Buy. Picked a little Aluratek universal Bluetooth receiver that came with a RCA cable to mate up to the old system. Wow. What an improvement!!!

Found a nice spot for the receiver and the center speaker on the shelf above the Performax in the center of the west wall.

Here's the tiny Bluetooth receiver. Pretty cool to be able to easily play my favs from my phone on the old system.

[SIGPIC][/SIGPIC]

One of the coolest shop tours vids I've ever seen, and the racing stuff is a BIG bonus.

On another note:

Guess that my now long ago sold '73 Ducati 750 GT is sure 'nuff a dinosaur. I had to keep the helmet as a reminder of the days when I was less brittle.

Bill

On the other hand, I still have five fingers.

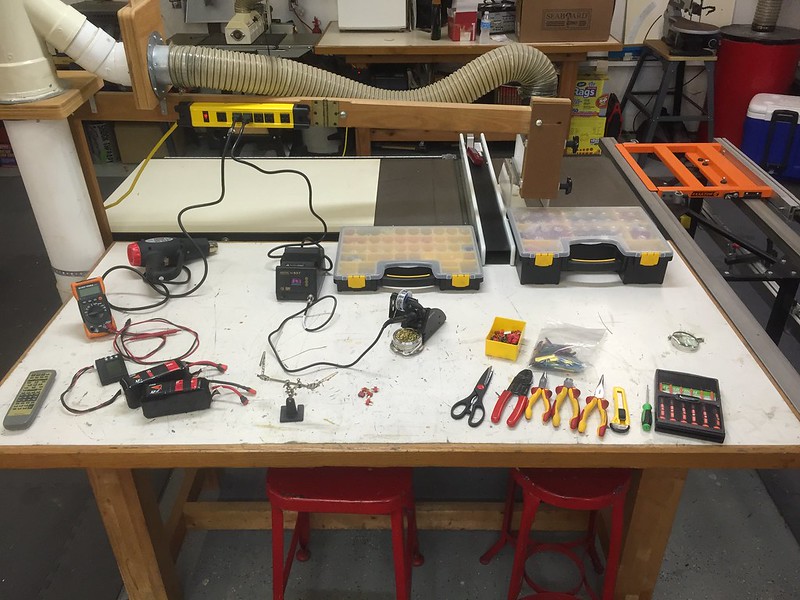

Few recent additions and updates to the shop. Nothing to do with woodworking but some needed updates for sure. I decided that I needed to step up my soldering game a bit as I have new modules for the dragster battery pack that need all the connectors changed before I can use them. I decided on the Aoyue 937+. Got it from Amazon for $60.00. Added some extra tips, solder, tip cleaning metal sponge etc.. so all together a little over $100 to get pretty seriously into the soldering deal.

Link at Amazon...

http://www.amazon.com/gp/product/B00...=sr_1_1&sr=8-1

I typically use the out feed bench behind the table saw for such projects but one thing that I've needed to do but never have is to get some electricity to that bench. A trip to Harbor Freight solved that. I got the heavy duty power strip and mounted it to the back side of my overhead guard on the table saw. $19.00 with the 20% off coupon.

Link to the power strip...

http://www.harborfreight.com/6-outle...ing-62437.html

All I need to do is solder wires and/or battery connections so this should do nicely for me.

[SIGPIC][/SIGPIC]

Now for the one thing leads to another file, I need a way to store the soldering station and accessories. Another Harbor Freight purchase solved that problem as well. I got the black 18x6x13 aluminum case with the dividers and foam padding. $24.00 after the 20% coupon. I'm blown away at how cool the case is.

Link at Harbor Freight...

http://www.harborfreight.com/tool-st...ase-62271.html

It is a nice looking case and appears to be well made.

Comes with thick foam and assorted dividers.

Removable tool holder in the lid.

There is egg crate foam behind the tool holder.

The edges of the case have the same sort of divider material so the interior is infinitely adjustable.

The foam is perforated in small squares so it is super easy to customize.

And here's the finished case. I still need to glue down the foam and the dividers but overall I am super happy with how this worked out for the soldering station. Pretty awesome deal for $24.00.

Last edited by Terry Hatfield; 03-12-2016 at 7:23 PM.

[SIGPIC][/SIGPIC]

That's an outstanding shop. And the electric dragster is very interesting and cool.

You must be a stickler for clean-up after working your projects & tasks. I'm in the processing of moving my woodworking tools to a basement shop location so I keep the sawdust out of the car projects and mechanical tools.

Thank you for posting all this. I've really enjoyed seeing what you've done. One day my shop will be there, in about 20 years!

Well a couple of years have passes and I've continued to work on and in the shop. I've rearranged and added quite a few things. Expanded into more metalworking equipment even though I'm terrible at it so far. I'll highlight some of the major changes and post a few overall pics from the latest set of shop pics.

The main additions are all metalworking. I added a Enco 105-111 mill/drill a few months ago. Kind of a cool story. Saw it a couple hours away on Craig's List for $500. Bought it from the original owner and got all the original paperwork and a good bit of tooling. He had built a base for it but I didn't care for it and built my own. I also did a complete restoration of the mill. I added a Z axis DRO and a few other goodies.

The stand is wood with a piece of a solid core door for a top. I had a stainless pan made to cover the door and added the aluminum tread plate side inserts and drawer fronts.

I milled Doug Fir construction lumber for the base. 3/4" baltic birch ply for the sides and back inserts. Drawers are from 1/2" BB and are 4 corner half blind dovetailed with 1/2" BB bottoms. All are on 100lb. full extension slides.

Bunch more mill restoration photos in this Flickr album...

https://www.flickr.com/photos/933967...h/43026791012/

[SIGPIC][/SIGPIC]

Also added a Grizzly G8688 mini lathe on a modified Harbor Freight 4 drawer cart and the most recent addition is a Grizzly G0752 10x22 lathe on a Husky 61" workbench from Home Depot. I bought the G8688 new and the G0752 was another Craig's List find. I did pretty major disassembly and restoration on the G0752.

I love the little mini and I did a lot on it but it's overall lack of power and size made we want something bigger.

So enter the G0752...

It was in good shape as far as bearings and such but was kinda ugly and very dirty. I did a good bit of maintenance along with disassembly, cleaning and refinishing. Lots of very poor paint on the lathe right from Grizzly. The carriage assembly had zero primer. Just painted right over the raw casting.

I made leveling plates and have done quite a few mods with more to come.

[SIGPIC][/SIGPIC]

I've also rearranged and added to the East wall. I bought a bench at Home Depot to house my Northern Tool 14: cold cut saw and Dayton 2x42 belt sander that I've extensively modded for grinding HSS tools for the lathe.

The modded sander. I removed the original platen and backer and fabbed a new platena nd backer from 2x3 tubing with a tool steel blacker plate and Pyroceram glass platen. I also made a new table from 1/4" steel plate.

The new platen assy.

Original vs the replacement.

The sanders does a fantastic job of forming the HSS blanks.

[SIGPIC][/SIGPIC]