I'm thinking about adding a power feeder to my table saw (which will have the router table in the extension wing).

I want to be able to use it for both the router table and the table saw, but have it fold down completely below the outfeed end of the table saw when I want it completely out of the way. I don't want to bolt it to the table top like a production shop would, where they have dedicated table saws for ripping.

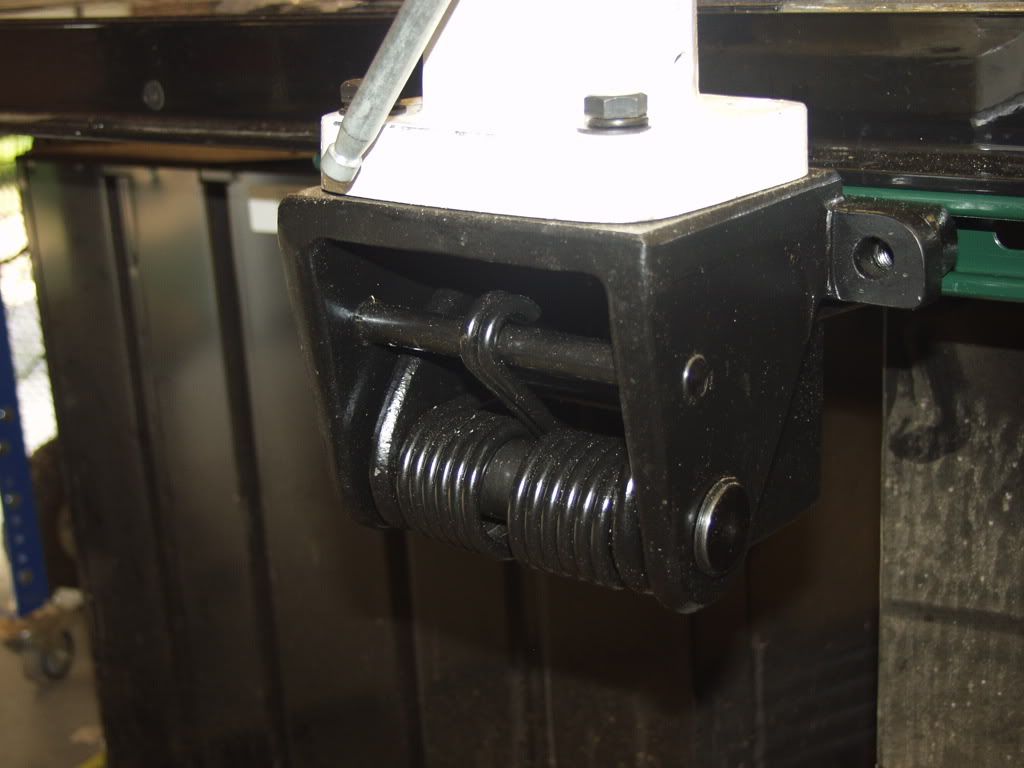

I'm blatantly steeling the idea from Felder (video fast forwarded to the right spot):

Has anybody retro-fitted something like this to a north american table saw before? I'm considering just buying the assembly from Hammer and fabbing up a mounting point somehow (I'm also a novice hobby welder, emphasis on "novice").

My biggest concern is the outfeed table on my saw. I want good support for rip cuts on plywood. I guess I could add second hinged section to my outfeed table to help with that.

Any creative ideas out there?

Reply With Quote

Reply With Quote