The house was over a hundred years old and was situated in a very up-scale neighborhood. Any investment in a good quality, home improvement was a wise one.

Their dining room & foyer, staircase & hallway… were the first places that were seen when you entered their home. We were asked to build wainscot to adorn all of these walls.

They wanted a more formal, frame & raised panel wainscot, not simply bead board with a cap, as seen in many 'turn of the century' country homes.

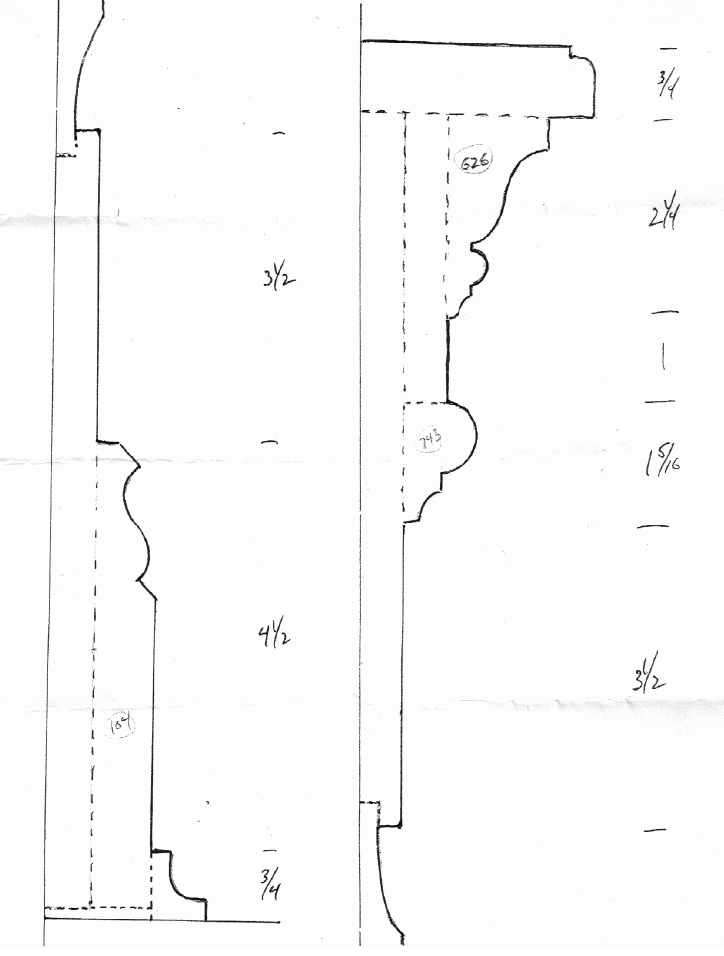

We created a sample of the wainscot 34" high but only 4" wide … based on their approval of the final profile drawing (showing the cap & base sections).

When we create wainscot of frame and FLAT panel area, we can choose final panel widths on location as these panels are formed simply by deciding where the stiles are placed. Since these panels were to be raised, they had to be made, ahead of time, in the shop… so we carefully measured all the walls to determined each of the final panel's sizes.

We had three radiator covers to make. Each had to ' fit ' within the wainscot very well … (both in terms of size & style). We first created the covers faces in the shop and sealed them well, backside & front.

I usually do a drawing of the frame & panel placement right on the walls. This not only verifies the sizes of the panels to be made back in the shop …but it also helps the client to envision what this 'wall covering' will look like. This becomes even more critical for those diamond-shaped panels climbing the staircase. Although not as flat as we would have liked, the existing walls were of lathe and plaster and solid as a rock. So we used construction adhesive and shot into the studs. We had made the panels a 1/4" less high & wide where there edges ran beneath the surrounding frame (stiles & rails) so we had more room to compensate for error. Here are 2 shots of the staircase being installed.

Our installation time was somewhat limited so we began installing panels and customizing the radiator's covers for a tight fit as the walls were less than truly flat & our painter began placing a final coat on those sections already completed. Here are two walls in the dining room freshly done.

The only way to see the whole job is to show this hand held, short video I managed to grab when I returned two weeks later to do another project for them. This good work payed off, it seems. Here is the link… / hope you enjoy how it came out...

http://youtu.be/imOwgRz07P4

Russell Hudson / Hudson Cabinetmaking, Inc. (you can reach my sire by clicking on my name at beginning of this article)

Reply With Quote

Reply With Quote