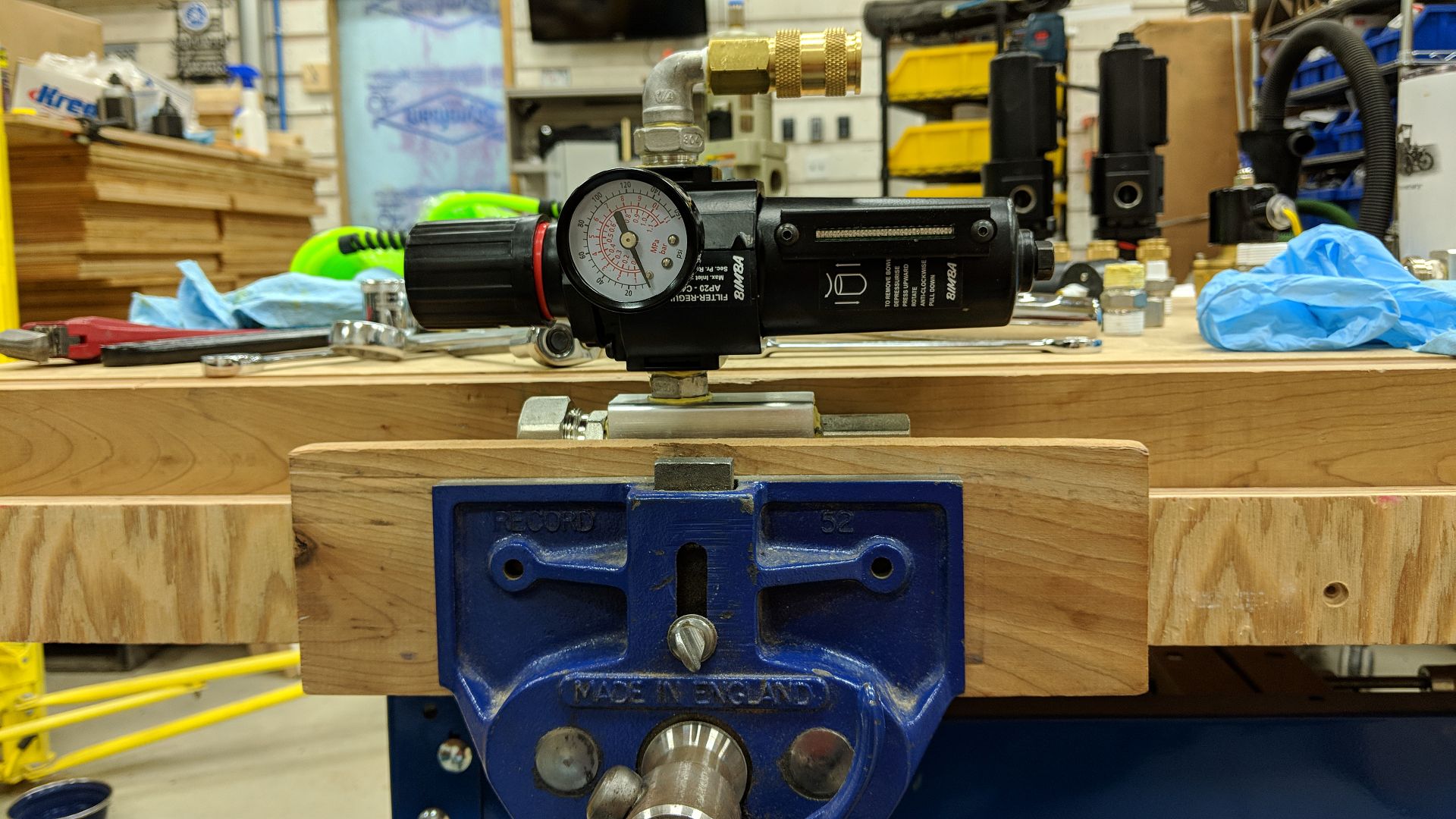

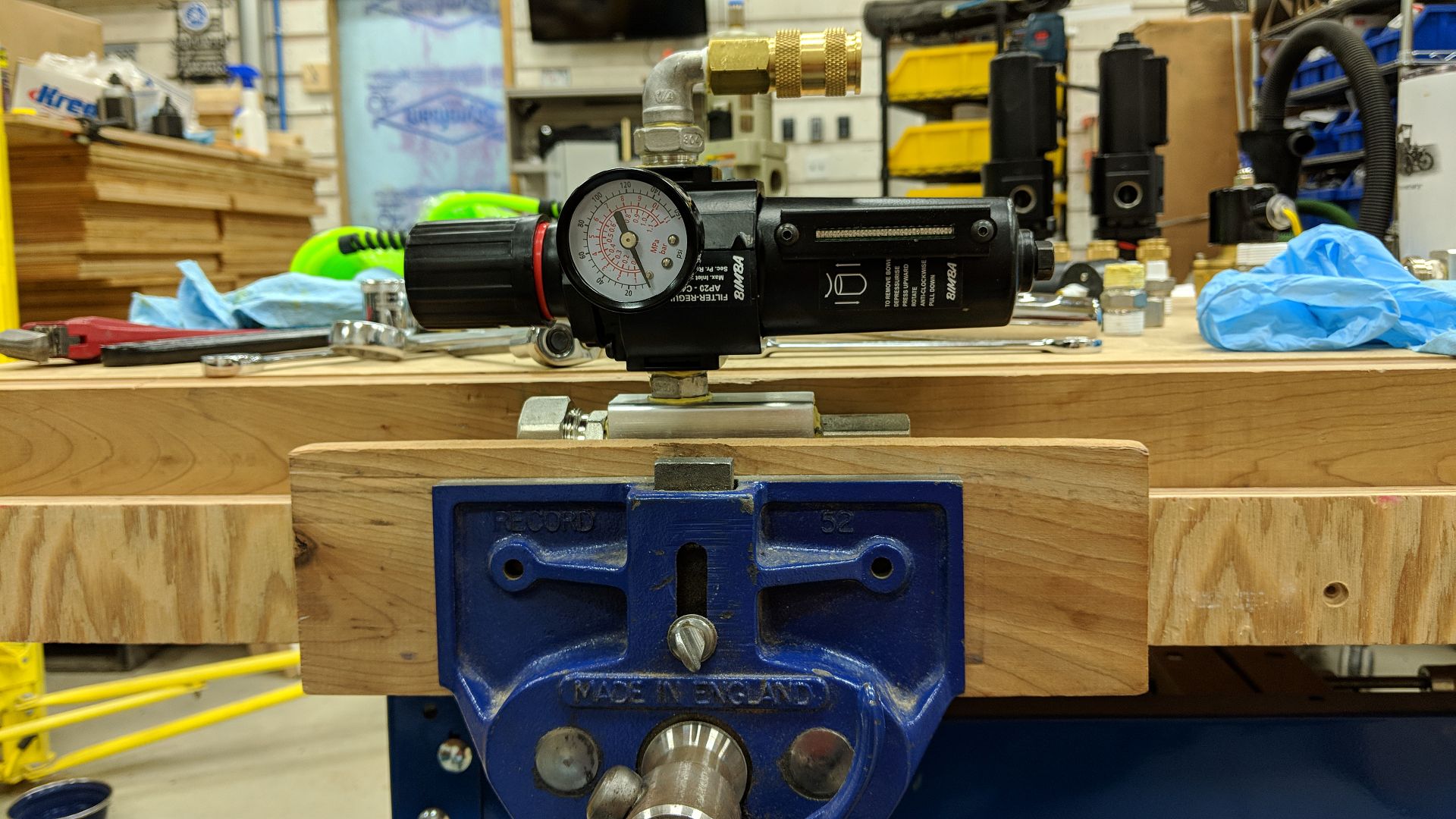

Blocks and fittings.

Blocks and fittings.

Looking great Mike. Are you beginning to see the light at the end of the tunnel? At least on the major part of the shop build.

Yes sir. 12x24 8' tall Mezzanine will be next Major shop add.

Nice to see I am not the only one to use my bench for non-woodworking tasks.

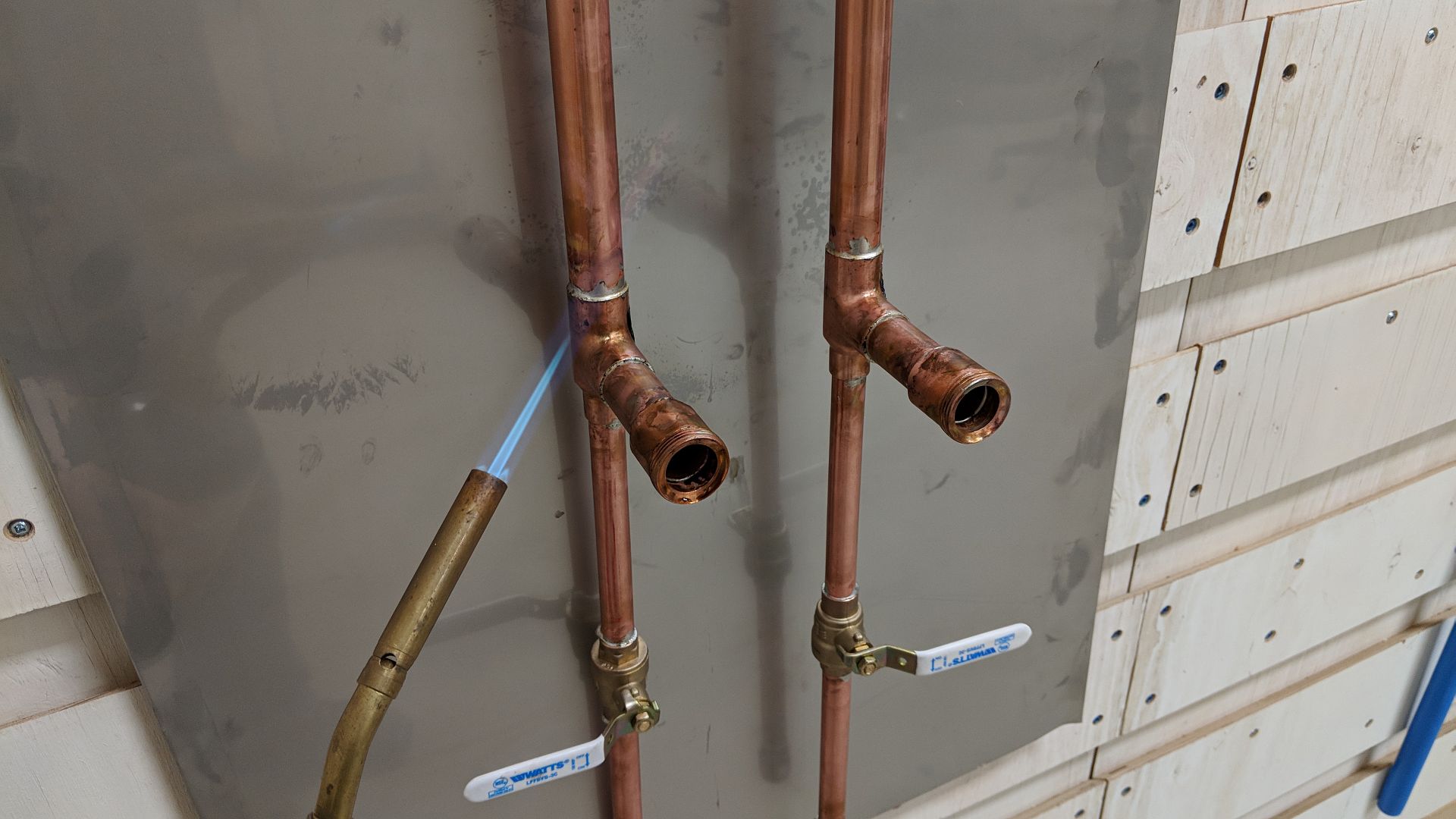

Built an aftercooler for the north wall airline setup. It is 50' of 3/4" type M copper. Also built a slat-wall soldering protection shield to protect my walls while installing it..

Compressor compressors air, some moisture goes in tank and now that has a timer drain valver to drain that. Air then goes through a ball valve and into an air regulator with a water seperator. Then it enters 50' of 3/" copper that has two verticles and two horizontals that slope down, and each vertical has a drain leg. That air in the copper aftercooler cools to ambiant room temperature and condenses even more moisture out of the air. Then it enters the r410 refridgerated dryer. Then it enters the main shop air line. The entrance vertical is the tallest. It branches around half the building to 5 drops and one ceiling run. All the lines fall away from the compressor. Each vertical drop has a drain leg and an air regulator with a water trap. The ceiling port is NC electric solenoid valve remote controlled. It will be for a mill drop out on the floor away from a wall. No good place for a ball valve on that. Ive sure tried a lot to ensure minimal to no moisture is in my air lines.

That should work great-belt, suspenders, raincoat, and armour. Where's the dryer drain? I'd like to see how much the water filters at the drops catch. I'd bet nothing left to catch.

The dryers drain comes out the back right. I have all the drains (tank, lines of aftercooler, and dryer) tied to 1/4 line. I just got tees today to run those into a wide lid oil recycling tank. Considering timed drain automationg the aftercooler too and also putting the dryer on a relay switched outlet to turn on when the compressor runs.

So I am going to try the Ventamatic ICF72 72" diameter Big Air Fans. Found a deal on them so I bought 4. More to come on those.

I will also work on the south wall aftercooler this weekend and get that dryer connected.

Glad its my shop I am responsible for - I only have to make me happy.

Very nice, looking good!

Unique opportunity today. High tension power poles are getting changed out next door. I let the crews use my access road. They are super happy with me. It was a slow clean up day. Talked to a gal who drives a big huge mountain size loader and she hooked me up with the boss. He had a track hoe guy help me move my mill into the new shed. After that five linemen the size of nfl linemen helped my Egyptian style roll it into place. Next tool to purchase, a real johnson bar like they have!!

They also cleaned out the back of my pond of willows and re terraced my back 4 acres with dirt. I bought the entire 25 man crew lunch. We get along great. Never underestimate the power of just being nice and buying folks a lunch. That pizza lunch saved me thousands of dollars in work today.

Crazy day!!

Very cool Mike! Good thinkin on your part!

Jeff

Great trade! I love trading for work. Just a little while ago, this afternoon, I traded a grading crew a place to dump stumps for doing a job that would have taken me three days with my tractor. They were having to drive 25 miles one way to dump a load of stumps, so they're getting a good deal too.

First fan is up