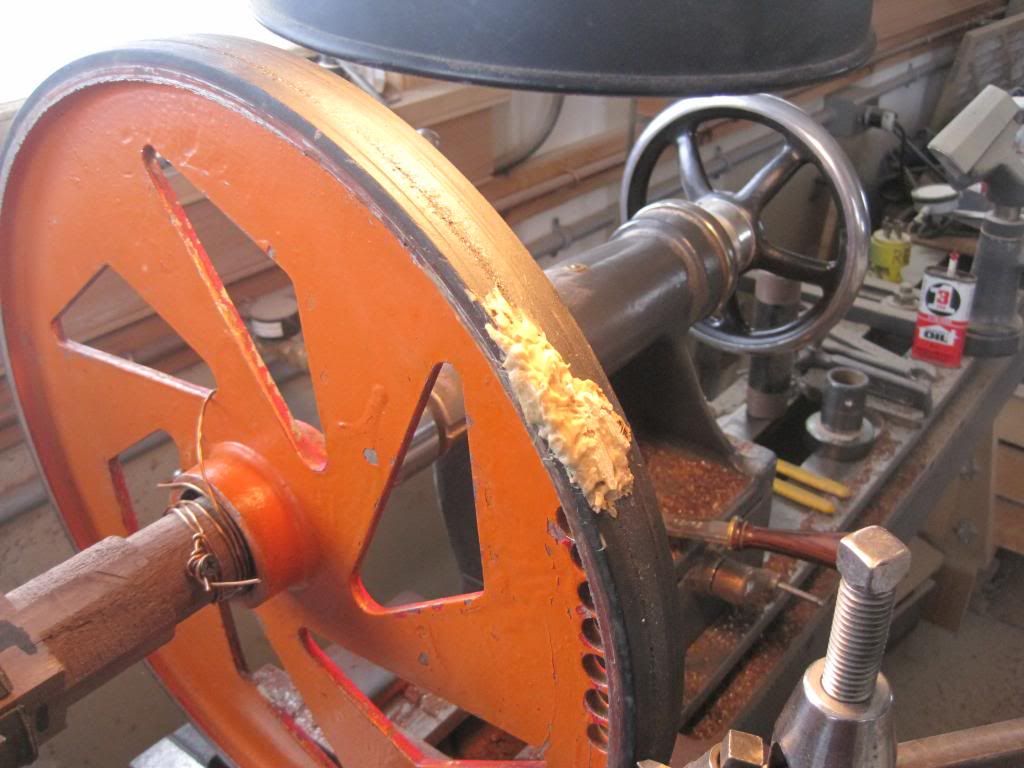

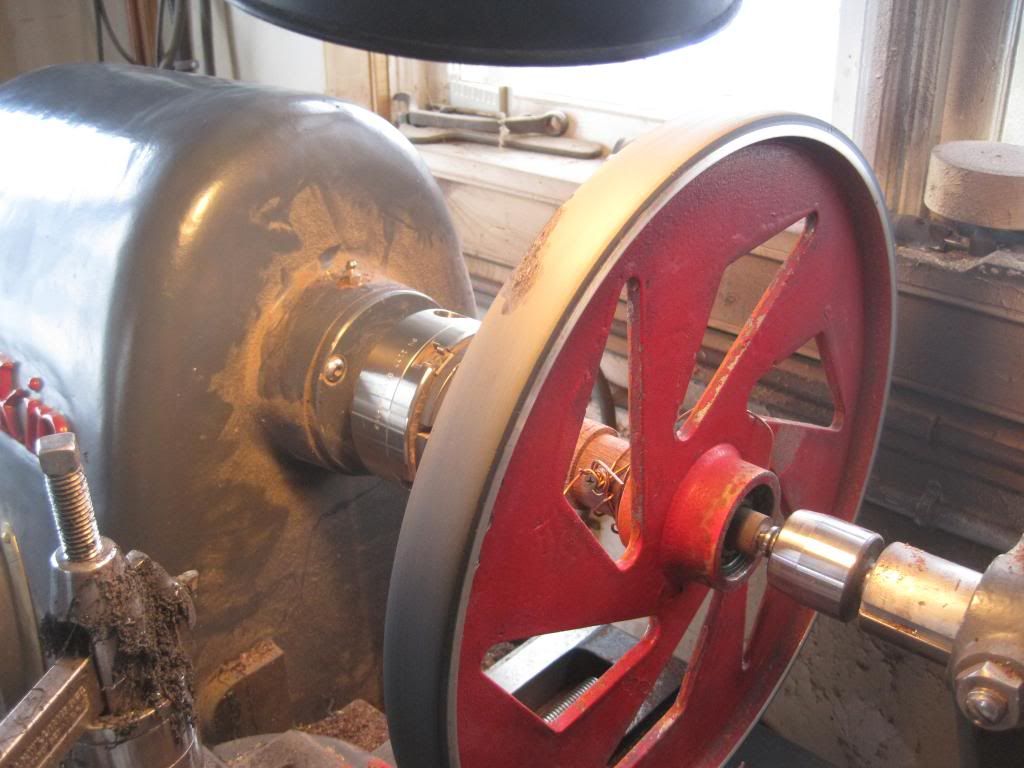

I have about finished restoring my WT band saw. The only thing remaining is to replace the tires while I have everything disassembled. Never done this before. The old tires look like black rubber and appear to have been glued on the wheel. From some of the articles I've been reading the tires need to be glued on and crowned. Any advise: what kind of glue, is glue really necessary, are urethane tires a better fix, and please tell me the best way to crown a tire and is that really necessary? Thanks.

Reply With Quote

Reply With Quote