Rationale

The conclusion after Session Three was (1) I had either not found the sweet spot for the very hard Jarrah I was planing, or (2) the effect of a chip breaker deflecting shavings is wood dependent.

Session Four

The plane is an unmodified Stanley #604 with LN chipbreaker (given a 70 micro bevel and slightly cambered) and a custom M4 blade.

This time around I chose a piece of Tasmanian Oak. For non-Aussies, this is (in my experience) similar in density to USA White Oak and also to European Oak. Tassie Oak is not an oak, however, it is a eucalypt. As such, it tends to be a little more interlocked. This piece was fairly typical.

How would I know if I was in the "sweet spot"? Well the video shows the shavings coming off the chip breaker vertically. This is why I have begun to think of the chip breaker (never again a "cap iron"!) as a "chip bender".

I set the chip breaker at a modest 0.3 (keep in mind that the chip breaker readings are slightly larger at the edge of the blade compared to the centre of the blade) ...

The mouth was "wide" at about 1mm. No effort was made to close it down as I normally would do for a smoother.

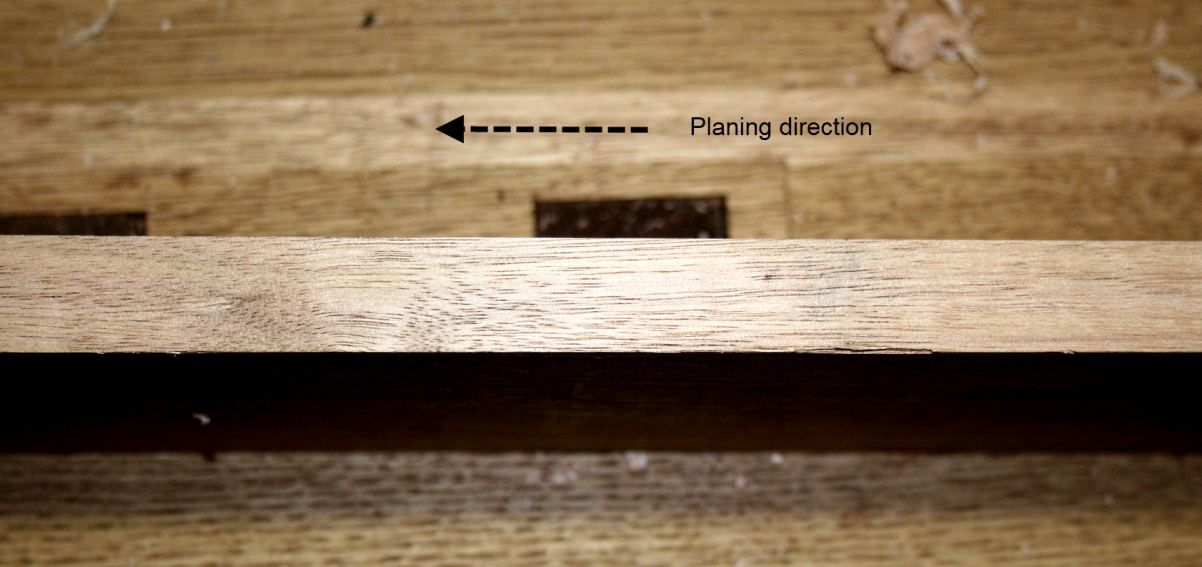

Here is the result ..

This was a good result. In the background you can see shavings from a chip breaker set back about 3mm. Those shavings are curled.

Of particular relevance here is that the planing took place into the grain.

The surface result was also superior - a shiny, clear and tear-out free finish ...

A close up around the knot reveals the absence of tear out ...

The second part of this session now moved to closing up the chip breaker to about 0.1 - 0.2mm ..

The result of this was very similar to Session 3, where the plane struggled to cut.

Clearly the chip breaker is now too close. However this is further evidence that it has a significant effect on the way the plane cuts.

For Part 3 the chip breaker was returned to the position of Part 1 ..

That particularly nasty piece of Jarrah (which is almost like end grain in the one section) was brought back. The #604 proceeded to plane this. The result was a little better than on the previous occasion, but not really that noticeably so. The board had some straight grained sections that were softer, and where the plane met this area, the shavings where long and straight. The surface quality was poor.

The LN #3 (with 55 degree frog, chip breaker set back 3mm) had its turn. The result was the same as before: decent surface to the touch, a noticeable improvement over the common angle #604 ...

The chip breaker in the LN was now adjusted to 0.3mm and the board planed again. The result was a significant improvement in the quality of the surface ..

This was repeated with the Veritas Small BU Smoother (with a 62 degree cutting angle). In the previous experiment the SBUS left a clearly better surface than the 55 degree LN #3. This time the SBUS was shaded ...

Neither LN nor SBUS produced shavings that were vertical. THis must be due to the high cutting angle.

Conclusions

There does appear to be a performance difference in the woods used thus far, indicating that the technique is likely to be wood dependent. The chipbreaker does, nevertheless, appear to be capable of improving the performance regardless of the wood type. However cutting angle does play a significant part as well, with a higher cutting angle still seen to be important for hard woods with interlocked grain.

Regards from Perth

Derek

Reply With Quote

Reply With Quote ).

).