Hi everyone,

i work in the Electrical industry and for the last year kept seeing these engraved panel labels at every customer that I visited, after some investigating and digging around I saw an opportunity.

by chance i found a guy who worked from home making these on a small scale for one or two clients, he agreed to take on some more work so i started putting some work to him and selling them on to a few contacts i have.

That was in Novemember, since then i have manged to make enough money and purchased some equipment.

I have the following.

Routout CNC Machine

Gravograph Beveller

Pillar drill

Bench saw with a carbide blade for cutting to size. not ideal but does the job.

I have manged to produce a few jobs myself but I am having issues with getting the depth of the engraving consistent, Its not been to bad on small lines of text but I have just been given a job to produce 30 logo labels and i am really struggling. The first line starts ok but as it makes its way along the label its not going deep enough and only just marking the material.

Also setting up for each label seems to be taking a while, re-positioning the Z axis and the depth being different to the last label i have done.

This is the only type of engraving I am interested in doing. I this machine ok for this or should i look at a different machine which wont have the above issues, something like a Suregrave Wizard or should I stick with this and try to figure out a better way of doing things.

My machine, MDF bed, the routed out area use to have a vacuum bed

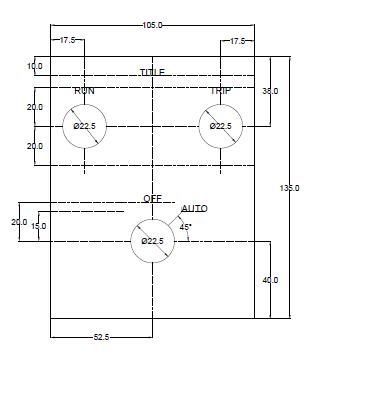

and the below is what i produce

Reply With Quote

Reply With Quote