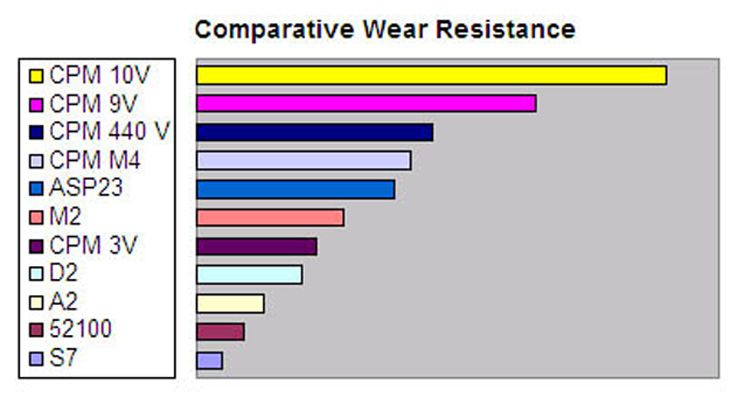

There has been considerable discussion about the merits of the "new" powdered metal super steels over the past year. Of course these are not new steels - they have been around quite a while and "old hat" to knife makers. However they represent new possibilities for woodworkers in the form of longer-lasting edges.

Longer lasting edges reflect high abrasion resistance, and the challenge with these super steels is to find an efficient and economical sharpening regime. Put away the Japanese waterstones, even the ceramic variety. Hide the sandpaper, and don't even admit to thinking that you may try oil stones .... none of these are effective. Yes, my Professional Shaptons do work, but ever so slowly, and you will be fooled (as I was) into believing that you have a working edge. The only medium that works effectively is diamond. I used diamond paste on a cast iron substrate with 40, 10, and 0.5 micron grits. With diamond, these steels were sharpened as easily as my A2 and laminated Japanese blades are on Pro Shaptons.

Using the above regime, all chisels easily pared Radiata Pine end grain as a pre-assessment screening.

The Steels

There are three powdered metal chisels, CPM 3V, CPM 10V and CPM M4. These blades were supplied by John Payne, who arranged for their heat treating. Hopefully John will join the thread and provide some details about their hardness and heat treating.

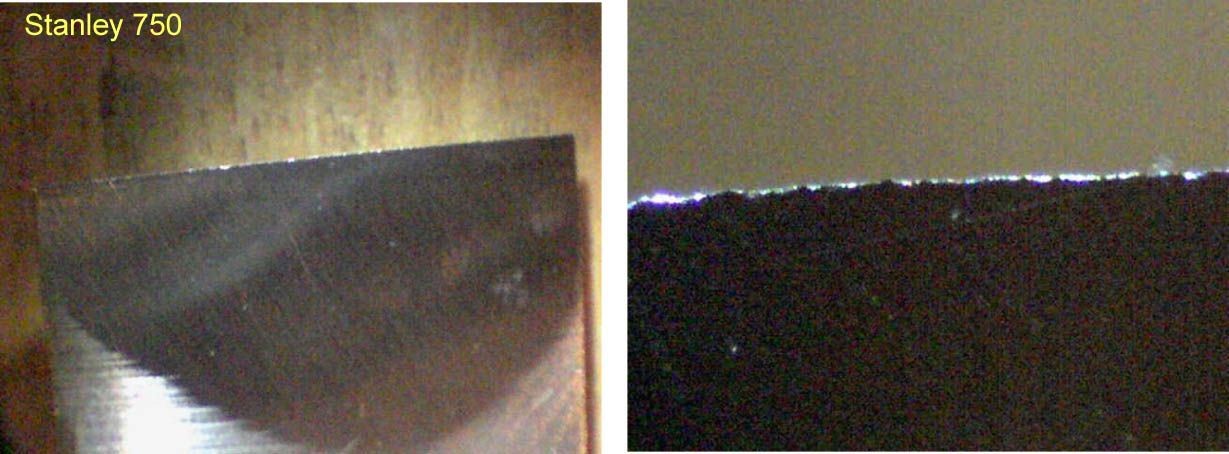

As a measure of control, I added a vintage Stanley 750 chisel, which is likely to be W1 steel. I also added a 30-year old Koyamaichi dovetail chisel, which I believe to be white steel. Stu Tierney will no doubt challenge me if I am incorrect

Five 3/4" chisels: 3V, 10V, M4, W1 (Stanley), and Laminated White (Koyamaichi)

The Test

I wanted a Real World evaluation, and so took the opportunity to chop out the dovetail pins in a 3/4" thick Jarrah carcase for a cabinet I am constructing. Each pin was 45mm in length.

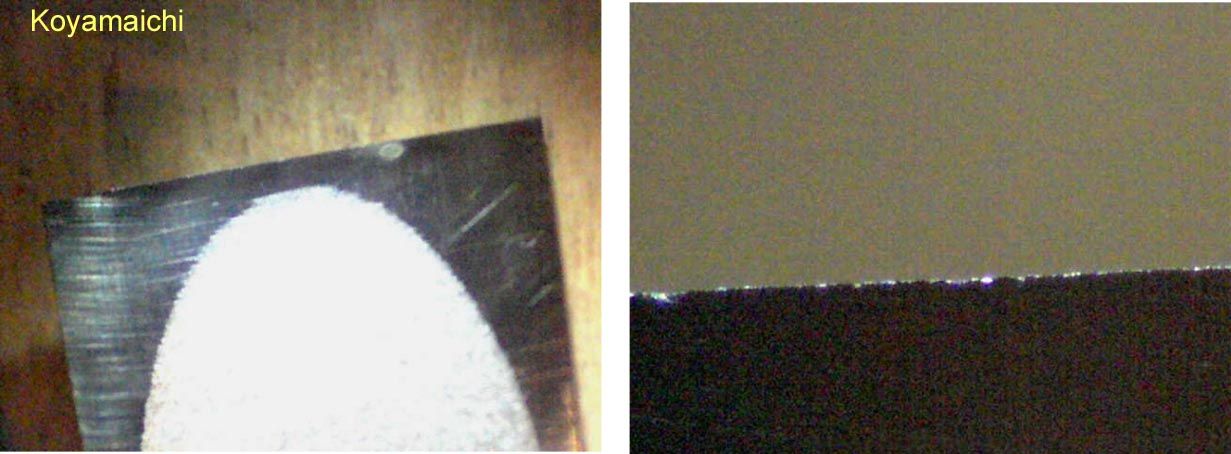

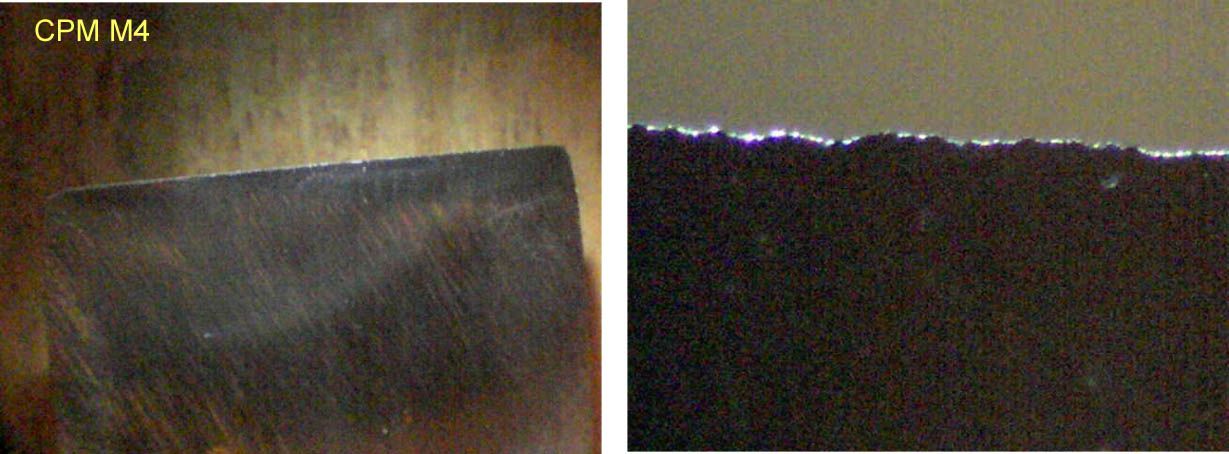

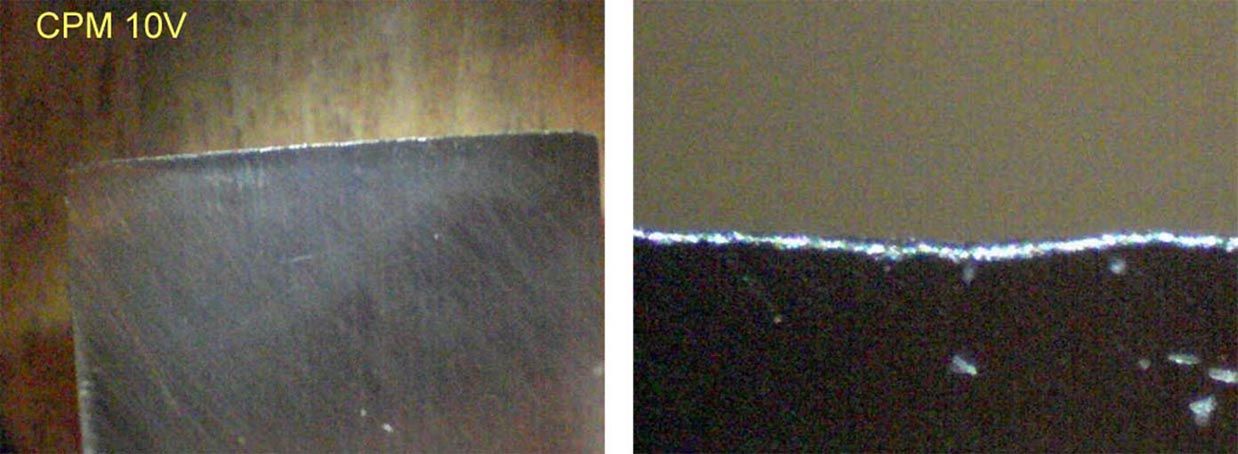

The method involved chopping out one half of a pin waste with each chisel in approximately 1/16" - 1/32" slices, checking the blade subjectively for a wire edge (by touch), testing the edge for sharpness by paring end grain Radiata Pine, turning the Jarrah board over and completing the removal of waste, and repeating the checks. At the conclusion, the blade edges were photographed at 200 magnification.

Half way ...

The Results

All the chisels were able to chop Jarrah waste even when the edges were dull. Few could pare end grain Pine comfortably after chopping the first half of the Pin waste, and only one chisel stood out as a tool of significant worth, the Koyamaichi. In second place was the M4 chisel, with the 3V coming in after this. The Stanley and 10V came in at the tail, with the Stanley just shading the 10V.

The Koyamaichi was outstanding. Not only did it fail to evidence signs of a wire edge (i.e. steel edge folding) at the half-way stage, but it was still paring end grain after 9 full dovetails. By contrast, only the M4 and 3V chisels were able to pare end grain at the end of a single dovetail, and at this stage they performed less well than the Koyamaichi did at the end of 9!

What of the Stanley? Well it did not disgrace itself and, in fact, did a very decent job. The 3V was tested initially with a 25 degree bevel (as this was the angle recommended). The Stanley (also with a 25 degree bevel) was better than the 3V in all departments (edge holding and performance) at this stage. However the 3V improved significantly when the bevel angle was increased to 30 degrees.

The Koyamaichi, M4 and 10V were given 30 degree bevels at the start (all recommended angles). This appears to be a good choice as the latter two blades developed only a fine wire edge. The wire edge on the Koyamachi was difficult to find.

Images

The images are in a set of two, with the first a magnification of 10X of the back of the blade, and the second image a magnification at 200x.

Koyamaichi ...

M4 ...

3V - note that the top images are with a 25 degree bevel, and the lower at 30 degrees ...

Stanley 750 ...

10V ...

In Summary

Relatively better performances from 3V and M4, and superlative performances from Koyamaichi laminated white steel.

Will there be a different presentation when the test is repeated, and will these results differ from blades used for planing?

Regards from Perth

Derek

Reply With Quote

Reply With Quote